From the 23rd to the 25th of January 2024, MUNICH FABRIC START will return as a critical meeting point for the European fashion sector, bringing together the “who’s who” of fashion makers and designers, to help influence and kickstart the development of their collections for the spring summer season 2025. Spanning an area of approximately 42,500 square metres, divided into eight areas – including THE SOURCE, BLUEZONE and KEYHOUSE – showcasing around 1,000 collections for the fashion and apparel industry from exhibitors worldwide, all within a highly professional working atmosphere. The elaborately staged trend forums and sample areas will present a concentrated essence of the new colour and material trends, innovations and inspirations for the season Spring/Summer 25 providing inspiration and guidance, and giving the industry some much-needed clarity at a time of historic uncertainty.

Key Takeaways:

- Uncertainty is everywhere – in geopolitics, in trends, and in supply chains – making it difficult for fashion to find the right way forward.

- For fashion professionals, this has turned clarity into the industry’s most sought-after commodity, making it critical for them to find the tools, have the conversations, and build the relationships that can provide it.

- From inspiration and education, to their unique spotlights on trend, technology, and transparency, events like Munich Fabric Start (taking place this month) have become important platforms for finding clarity in an uncertain world.

Introduction: Clarity 2024: Information, Innovation and Inspiration

2023 was a year characterised by uncertainty. The fashion industry faced many economic challenges around cost and price pressure, soaring energy prices, inflation and recession. This also coincided with an increased need for transparency – driven by consumer buying patterns and legislations across different markets. Against this backdrop of uncertainty, regulation, and unpredictability, fashion struggled to find a confident way forward.

The Interline and Munich Fabric Start (MFS) wrote last year about how to overcome these challenges: fashion professionals need to embrace both innovation and inspiration, adopting new technologies and materials, as well as looking beyond the limits of fashion to find ideas and solutions from other industries.

In 2024, MFS will be even more focused on creating the conditions and providing the foundations for this clarity, in light of the continuing unpredictability that is shaping the fashion landscape. Through its educational programmes, sourcing tools, exhibitors, and trend insights, MFS is prioritising clear structures and simplification as a way to provide a roadmap for fashion that takes account of not just the whole-sector, whole-enterprise challenges and the uncertainties that are shaping the future, but the opportunities that overcoming them can create.

The event’s seasonal themes – Sublime Craft, Sensual Mind, Provincity, Uncharted, and Joy Inside – reflect the momentary complexity of fashion: from newly interpreted craftsmanship to the rediscovery of one’s own “I”, the synergy between city and country and the fascination for the unknown. The final, overarching theme is ‘responsible optimism’ – a reminder for fashion professionals to be active and confident in shaping a sustainable future for the industry, not just a response to the need for more sustainable products, but a fundamental reorientation of fashion with confidence and clarity as its foundations.

Where Fashion Needs Clarity and Transparency

A key part of clarity is transparency. Understanding where things come from, how they are made, who makes them, and what inspired them is a way to build accountability, ensure ethical practices, align teams to a creative, and champion sustainability.

Understanding where fashion can benefit from transparency – and what forces are creating the drive towards it – will be critical to developing a vision for building both short and longer-term clarity.

Supply Chain

Transparency in the supply chain is the guarantee that the journey of raw materials, production processes, commercial relationships, and distribution is clear and accountable. This includes visibility into working conditions, wages, and environmental impact across the extended product lifecycle.

As with much of the legislation in fashion and textiles, the EU is leading the market in pursuing and mandating traceability in supply chains. The upcoming Corporate Sustainability Reporting Directive (CSRD) mandates standardised reporting on environment, social and governance (ESG) activities, while the Corporate Sustainability Due Diligence Directive (CSDDD) enforces environmental and human rights diligence across the value chain.

The fashion industry, in particular, faces a debate over the requirement for standardised disclosures, with many in senior leadership expressing concerns about the extensive data and analysis needed. The EU’s new rules are anticipated to impact not only the EU, but also Asia – a major manufacturing hub for EU textiles. Global initiatives, such as the New York Fashion Sustainability and Social Accountability Act in the US, the Green Claims Code in the UK, and China’s commitment to carbon neutrality, further define the international regulatory landscape to make for a more transparent supply chain.

Wherever we look, upstream, transparency is – correctly – seen as both a challenge to be solved, and an opportunity to be capitalised on, with the common thread between these two strands being the understanding that both outcomes hinge on the idea that visibility generates clarity.

Business-wide Sustainable Practices

Consumers and other fashion stakeholders increasingly demand transparency regarding brands’ and designers’ commitments to sustainability – translating visibility into accountability. This involves disclosing efforts to reduce environmental impact, use eco-friendly materials, and adopt circular practices. And this, too, is an area where heightened scrutiny into historically opaque processes, workflows, and relationships is exposing a need to replace complexity with simplicity, and uncertainty with confidence.

In March 2022, the European Commission embraced the Product Environmental Footprint (PEF) method as a tool to assist companies in gauging their environmental performance through a science-based, standardized framework. This method comprehensively assesses impact across 16 environmental indicators, including carbon emissions, water use, freshwater ecotoxicity, and land use. Aligned with the European Green Deal and circular economy aspirations, the PEF methodology serves to advance environmental objectives within the European Commission by applying standardisation to a due diligence process that many fashion brands have struggled to adequately describe, delimit, and disclose.

The CSDDD is also relevant here. This directive requires companies to analyse and address the environmental and social impacts associated with their operations and supply chains. By necessitating a thorough examination of potential risks and adverse effects, the directive seeks to promote responsible business conduct. It advocates for transparency, ethical sourcing, and the infusion of sustainable practices across the entire spectrum of production and distribution processes.

Product Information

Providing accurate information about products – including materials used, manufacturing processes, and care instructions – enhances transparency and helps consumers make informed choices, at the same time as providing a framework for creative, technical, and commercial teams to work towards.

France has been a leader in this area, adopting an ambitious French Anti-Waste for a Circular Economy Law (AGEC) in 2020 to shape a system-wide transition towards a circular economy. This comprehensive legislation mandates verified environmental labelling from 2024 onwards – coming into effect shortly before Munich Fabric Start. It applies to all fashion stakeholders, including producers, importers, distributors, or entities with an annual turnover exceeding €50 million, responsible for introducing a minimum of 25,000 waste-generating consumer products to the French market. The enforcement of environmental label requirements follows a phased approach, beginning with major corporations and gradually extending to small and medium-sized enterprises (SMEs) over the coming years.

The information that must appear on the labels of textile products are: sustainability, reparability and durability, recycled material content, recyclability, re-use (for packaging), traceability (country of manufacturing operations), presence of plastic microfibers, and use of renewable resources.

Marketing Claims

Greenwashing has become an issue for the fashion and textiles industry, and it is essential that any claims made around sustainability and ethical practices are transparent and backed by verifiable evidence. What will help push everyone in the right direction is the provisional agreement reached on 19 September 2023 by the European Parliament and Council, providing new rules governing environmental claims. This follows the European Commission’s proposal for a Directive (the Green Claims Directive) which was published in March 2023.

Technology Facilitating Transparency

Across all of these areas (and others) clarity and certainty are fast becoming the core currency of effective, sustainable, creative operations. From disclosing the extended journey that a product takes to market, to enabling designers, technical developers, sourcing managers, and other fashion professionals to make informed decisions, clarity (enabled by transparency) is a key foundation for the future.

From a technology perspective, what solutions exist to help obtain it?

Blockchain

This technology can be used for recording every transaction or movement, providing a secure and unchangeable ledger. Each garment can be assigned a distinct digital identity through blockchain, guaranteeing that details regarding its origin, materials, and manufacturing processes are secure, tamper-proof, and verifiable.

Important to note about blockchain: the information presented is not, by definition, be accurate and complete. Unfortunately, many brands currently grapple with limited insights into their suppliers, lacking reliable and standardised data for substantial progress. It is also crucial to acknowledge that blockchain is a relatively recent innovation and currently operates within a largely unregulated environment. To overcome this challenge, fashion needs to establish a clear set of established standards or certifications to guide its development, as well as acknowledging the vast amount of energy it uses. Additionally, its associated costs make this technology prohibitive for smaller labels and retailers at present.

Nonetheless, the technology stands as a promising technology with the potential to enhance the authenticity, traceability, and transparency of products within the fashion supply chain.

RFID (Radio-Frequency Identification)

RFID is used widely: in manufacturing, inventory control, warehousing, distribution, logistics, automatic object tracking and supply chain management. RFID tags on products enable tracking throughout the supply chain, allowing stakeholders to monitor the journey of items from production to distribution. The technology uses radio signals for the individual identification of each clothing product, and RFID hardware tends to come equipped with memory storage and a security alarm for product ID installation.

The integration of RFID technologies has the potential to enhance the advantages of supply chain management by minimising inventory losses, amplifying the efficiency and speed of processes, and elevating the accuracy of information.

Digital Product Passports (DPP)

The European Commission defines DPPs as tools to provide information about a product’s environmental sustainability. The DPP is essentially a digital record of a product’s sustainability and circularity information throughout its lifecycle, from design to end-of-life. Although the details of the implementation of DPPs are still unclear, the industry is preparing for this new regulation that would represent a significant improvement in our products’ performance and transparency. And as extended producer responsibility becomes more widely adopted, events like Munich Fabric Start (which encompass the full sourcing and value chain for fashion, from materials and trims to technology) are likely to remain the places that fashion professionals go to identify the right tools to establish this certainty.

Overcoming Technology Adoption Challenges

While the potential for improving traceability in the fashion supply chain is encouraging, there are still various technical challenges that can hinder widespread adoption. These challenges include complexities in implementing digital traceability systems, the associated costs of system upgrades, and concerns about the reliability and security of such digital systems. Overcoming these obstacles will require the prioritisation of regulatory, technological, and communication frameworks within the fashion industry that promote collaboration, security, and scalability. Building trust in these traceability systems is critical, requiring transparent communication from digital developers about the accuracy, security, and credibility of their solutions. To further progress, there should be increased collaboration among governments, industry stakeholders, and technology providers to develop scalable and cost-effective solutions – as well as deep and ongoing educational efforts like those put together by leading events like Munich Fabric Start.

Exploring the Latest Innovations at MFS

Fashion’s value chain is in the midst of meaningful revelation of its direction, its priorities, and how much of the future can be assumed based on the past. Against that backdrop, it is up to each company to scrutinise each step – design through distribution – with the clear objective of being more sustainable, efficient, creative, and innovative. The incorporation of digital processes, new materials, decentralised production, smaller batches, reduced lead times, extensive transparency, and innovative circular business models all contribute to fashion’s new show that embraces clarity in every sense. This means establishing streamlining processes amid our current complex fashion environment, creating transparent production and supply chains, presenting compelling fashion themes, and incorporating meaningful use of colours, silhouettes, and materials.

Below are a selection of some of the innovations that will be showcased at MFS next week, bringing together process interventions (i.e. materials and dyes), software innovation, and overall digital transformation.

New Materials and Natural Dye

- CO2Tex: Innovative elastic yarns bind CO2. CO2Tex establishes commercially usable elastic filament yarns made from CO2-containing thermoplastic polyurethanes as an alternative to conventional elastanes. The aim of the “CO2Tex” project is to establish commercially viable elastic filament yarns made from CO2-containing TPU. At the end of the project, these yarns can be processed as easily as possible on existing industrial plants into yarns and textile preliminary and end products to replace conventional elastane. There is also the possibility of opening up new fields of application with these innovative TPU yarns.

- BIOBASE: a central project within the BIOTEXFUTURE cluster, introduces sustainable alternatives from available resources for textile applications with competitive costs and properties. The project is motivated by the challenge of dependence on fossil raw materials in the production of synthetic polymers, which poses ecological, economic, and political risks. The project targets the establishment of biobased polymers in the textile industry, demonstrating their full potential. Key sectors of the German textile industry, including automotive, sportswear, interiors, and technical textiles, are the focal points.

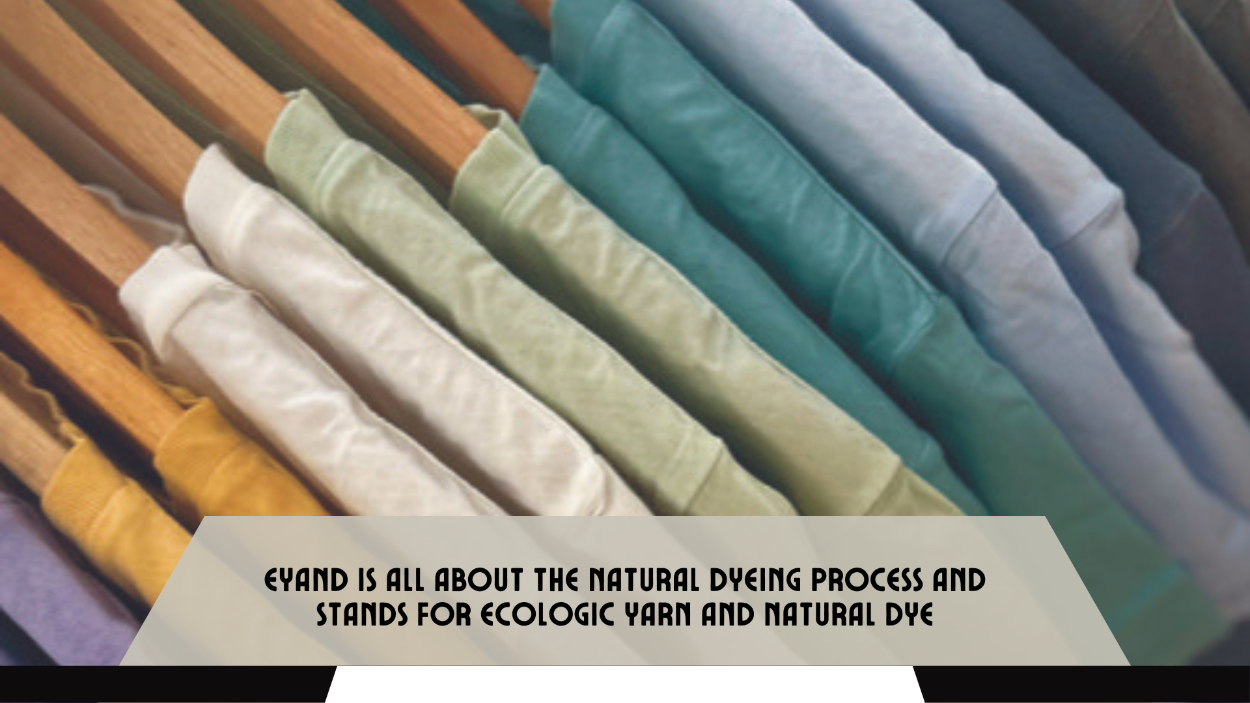

- EYAND: is all about the natural dyeing process and stands for Ecologic Yarn and Natural Dye. EYAND presents a collection with a large range of natural colours, all with very good colour fastness. Certified with Oeko-tex and GOTS. Their natural dye cotton, wool, cashmere and silk garments offer a full package service from the knitting of the fabric, Inhouse workshop for pattern making and proto samples and garment dyeing with their natural colours.

AI:

- YOONA.AI: This technology seamlessly merges Data Analytics and Generative AI, revolutionising design as a collaborative interplay between human creativity and technological expertise. Every stroke, colour, and form is shaped by data-driven insights and empowered by AI-generated possibilities. This innovative synergy transforms design into a dynamic, strategic process, aligning aesthetics with market trends. Yoona AI Suite charts a course toward an evolved design landscape that captivates aesthetically while staying finely attuned to the pulse of the market—a fusion where human ingenuity dances alongside technological advancement, shaping a visionary future for design.

Upcycling and Recycling:

- EEDEN: enables the production of fibres such as Lyocell, Viscose, or Polyester from end-of-life textiles. They have developed a holistic upcycling technology to extract cellulose and polyester from discarded fabrics. Their process is in line with EU regulations, conserving resources and offering a scalable, circular solution to the waste challenges of the textile industry. Visit them at the KEYHOUSE and learn more about their upscale.

- LEMAR: The Spring/Summer 25 Collection of Lemar continues to uphold their commitment to eco-conscious fashion. At the heart of this collection is Q-Cycle by Fulgar™, a revolutionary approach that incorporates end-of-life tires into the mass balance technology used during its production, minimising waste and giving a new life to materials that would contribute to environmental challenges. Join Lemar to weave a better future.

- Denim Deal: The Denim Deal is part of the Dutch Circular Textiles Policy Programme 2020-2025 with targets for the recycling of post-consumer textile waste and on the use of recycled content in new textile products in 2025 and 2030. The Denim Deal started in October 2020 with 28 signatories who aim to close the denim loop by promoting the use of high-grade post-consumer recycled cotton fibres (‘PCR-cotton’) in new jeans and other denim garments. Since the start in October 2020 the number of signatories has grown significantly up to 53, including brands such as PVH, Scotch & Soda, MUD Jeans, 247 Jeans, KOI, Garcia, and Kuyichi.

For more information on unique textiles, modern and sustainable processes, evolving technologies, and the newest innovations for fashion, visit the MUNIQUE BLOG.

MFS: a Facilitator of Connection and Clarity

Fashion begins not at the needlepoint, or in the process of sourcing, but earlier – in the minds of designers, through global trend research and in the collaboration of fashion brands, fashion houses and brands with fabric producers, weavers and trend experts. Fabric trade shows like MFS are the most concentrated form of this creative exchange. Only there, fashion designers and creators can gain a comprehensive overview of the coming trends – and the possibilities of transforming them into their individual collections – in a short time and on limited space, and at the same time as exploring and educating themselves on ways to overcome uncertainty and build clarity.

MFS brings together trends in a uniquely condensed and profoundly researched manner with an exhibitor portfolio of 1,000 collections that comprehensively reflects the production market in all fashion categories: FABRICS, ADDITIONALS, BLUEZONE, DESIGN STUDIOS, ReSOURCE, KEYHOUSE with SUSTAINABLE INNOVATIONS and THE SOURCE.

Discover more information about the exhibitors at MFS’s January 2024 event here.

Conclusion

2024 is the year of clarity and responsible optimism. But this clarity will not be something that the industry simply stumbles upon, it will require active participation, engagement, and a constant willingness to learn and to be challenged. By embracing clarity as described here, the fashion and textiles industry can working towards a more connected, collaborative, and sustainable future.

Tradition and technology seem to be antithetical, but in today’s fashion world, the two can complement each other and serve as mutual sources of inspiration. Both can underscore the importance of quality and conscientious consumption. MFS acts as a facilitator, as well as a driving force, for more openness, sharing of information, and creativity – especially at this moment where confidence is needed to put concrete action into place.

About Munich Fabric Start:

With 900 international exhibitors on a total area of around 42,500 square metres, the international fabric trade show MUNICH FABRIC START is strongly booked. The BLUEZONE features around 100 international brands. The conference and lecture programme of MUNICH FABRIC START, BLUEZONE & KEYHOUSE is more comprehensive than ever. More than 50 speakers will pool their expertise and discuss current developments, changes and challenges in the industry. The event’s programme conveys competence and professionalism combined with inspiration and innovation and will once again attract up to 20,000 trade visitors from management, product management, design and purchasing to Munich from 23 to 25 January 2024.