The environmental and social costs of fast fashion are immense. The industry heavily impacts pollution levels, water resources, carbon footprints, human rights, and gender equality. As these challenges continue to grow, the necessity for sustainable fashion is more pressing than ever, for brands across the board. When purchasing swimwear, it’s often tempting to choose inexpensive fast fashion brands that appear to be bargains. Unfortunately, these brands typically use low-quality materials and design their products for quick obsolescence, resulting in the need for replacement after only a few wears. This culture of waste is one of the main reasons that JVBswim exists, and the brand is working to promote and progress the fashion industry into zero waste practices. Getting there is by no means an easy task and will require a massive change in current industry practices – from fabrics uses, ways of working, to post-consumer waste – but there has never been a better moment for it given the consumer gravitation towards sustainability as well as the maturity of 3D/DPC technology.

Even so, creating a truly sustainably driven fashion house from conception requires the drive of an altruist with a dash of masochism. From conception, JVBswim is built with three pillars: responsibility, empowerment, and integrity. Working to create and drive truly sustainable fashion practices, test and push design, production, and customer interaction boundaries to reset the status quo. At times, it’s been tougher than Tarzan’s toenails, but worth the ultimate reward: creating a shift in the current , and often environmentally and socially harmful, apparel industry. For me, tangibly this looked like millions of yards of fabric produced in days, millions of a single unit selling out in weeks, and then restocking. I had to wonder: where does it all end up? What drives this consumption? So, with a decade-plus of professional experience in the mass market and expertise in women’s swimwear, I assessed the process from design through to consumer psychology in order to reshape and progress the industry’s practices and build JVBswim to meet current and future zeitgeists’ supply and demand.

Swimwear is a rising contributor to landfills with accessibility of vanity labels and consumer single use mindset trends. Made from fabrics derived from petroleum and plastics, swimwear not only pollutes the earth in its creation – but never leaves the earth upon it’s disposal. A deep dive into the production of recycled or new eco-friendly fabrics – research, interviews, and speaking with companies at the forefront of fibre and fabric creation, unearthed the negative environmental impacts of the fabric’s production and end-life impact. The psychology of over consumption would be harder to address, with ego, greed, ignorance, and a culture of instant gratification. Nevertheless, JVBswim drafted a solution of change by taking a step back, assessing the big picture, and turning to my roots for inspiration.

At the age of four, inspired by my grandmother’s passion for sewing together we began creating clothing for my dolls with materials from church swaps and local fabric deadstock importers. This led to creating my own clothes with the same techniques in my formative years. In college, the tradition continued at Kansas State University, where the fashion studies program taught the industry end to end, focusing on designer responsibility and sustainable practices, and continued sewing for my side business making dresses for sporting events from t-shirts donated by alumni. Working professionally, with scraps from headers, ruined samples, discarded trims, and sample fabrics, I’d make swimwear for fun. From this lifetime of practice, I committed to scaling these methods into my own fashion house and an integrative B2B and B2C zero-waste consumer-driven apparel platform: JVBswim.

The first objective was to establish the sourcing pipeline, and so the journey of sourcing deadstock fabrics for full-scale production began. Living then in Hermosa Beach, California, I hopped in my car to the Los Angeles fashion district – navigating through the miles of allies and stacks of materials, until connecting with the right luxury swimwear deadstock and vintage fabrics suppliers. Establishing a local deadstock fabric pipeline achieved the following key objectives: minimised contributions to landfills, eliminated chemical pollution incurred with the design process, and reduced the carbon footprint and waste from the packaging and transportation of the sample approval process.

With no shortage in a variety of deadstock fabric for womens’ swimwear, JVBswim is not limited in design. But, the depth of the deadstock fabrics presents two challenges: producing inclusively with limited quantities and scaling for supply to meet growing demand. Producing limited quantities intensified the need for well-planned production to ensure profitable cuts. For new styles and colours, pre-sale launches and made-to-order options accurately forecast production runs, while still allowing the customer options in styles and sizing. Ensuring supply meets demand is more difficult, but the limited batches naturally create immediacy and exclusivity for the consumer and helps retain its “specialness. To scale, Solid colours can be restocked with similar versions, and for print restocking, prepared for print (PFP) deadstock and sustainably printing with local or domestic vendors maintain the integrity of our mission as the brand grows. With zero-waste commitment, fabric-cutting waste is saved for development sampling, packing ribbons, and future projects for reducing costs and materials.

Having a pipeline that met sustainability goals for materials, the foundation was laid for the second objective: eliminating overproduction through laser-focused on output maximisation. Again, the past inspired the future.

With a professional background in pattern-making, design, and product development and being an avid sewer, custom designs were the beginning of JVBswim. Working directly with the customer had the benefits of providing valuable insight and removed guesswork. With a bit of momentum and an amazing network of support, the Jillian Von Beyer take-over shop opened, featuring handcrafted sets from deadstock fabrics and vintage laces. Speaking with each customer, adjusted the fit, heard their needs, – the shop sold out less than 48 hours later, inspiring the customer-driven design experience to create zero-waste personalised development. Analysing each level of the process, supply chain, and customer experience allowed JVBswim to lean into creating zero-waste customer-driven design technology. Pulling inspiration from the automobile and video game industries, I immersed myself in learning how to apply their technology and practices to further sustainable apparel production and experience and fulfil the customer’s shopping and psychological gratification needs.

Scaling presented the third objective: scale while maintaining integrity. – Local production presented a natural solution. Domestic production had been part of the master plan since my second year at Kansas State University, during which- out of my love of fashion history and passion for sharing knowledge- I was a docent at the college’s Nelly Don exhibit during its semester-long showing. Nelly Don, like me, came from humble beginnings in the state of Kansas; sewing, creating her own opportunities, and dreaming big. Don is credited with bringing ready-to-wear apparel manufacturing to the midwest by way of her factory Donnelly, a legacy JVBswim hopes to continue by way of streamlining on-demand production.

JVBswim is currently produced in San Diego, California. Upon moving to San Diego from Hermosa Beach, work began to find local producers that could be a true partner in growth. Los Angeles has amazing small production options, but were still out of the start-up budget and the minimum quantities were still too large and turned to San Diego to find a partnership that would work with JVBswim to grow. Serendipitously, when my industrial serger had its post-move tune-up, the serviceur took a call, and overheard the name of a producer who has become an integral partner of JVBswim. Not only did finding this local partnership eliminate overproduction and allow for on-demand and extremely fast lead times, but it also eliminated packaging waste, minimised carbon emissions, and, being women owned and operated, supported all three pillars of JVBswim of empowerment, integrity, and responsibility.

Partnering with the local women-owned sewing facility created a sense of empowerment beyond marketing partnerships or flattering styles. It also guarantees the empowerment and support of local artisans and garment workers. Allowing for face-to-face interaction to effectively work through sampling requests, dropping by cuts for small run productions, and receiving order batches directly upon completion greatly increases efficiency and streamlines go-to market. There is no lag time in communication and shipping delays are non-existent. This partnership has allowed JVBswim not only to scale growth, but to do so intentionally and responsibly.

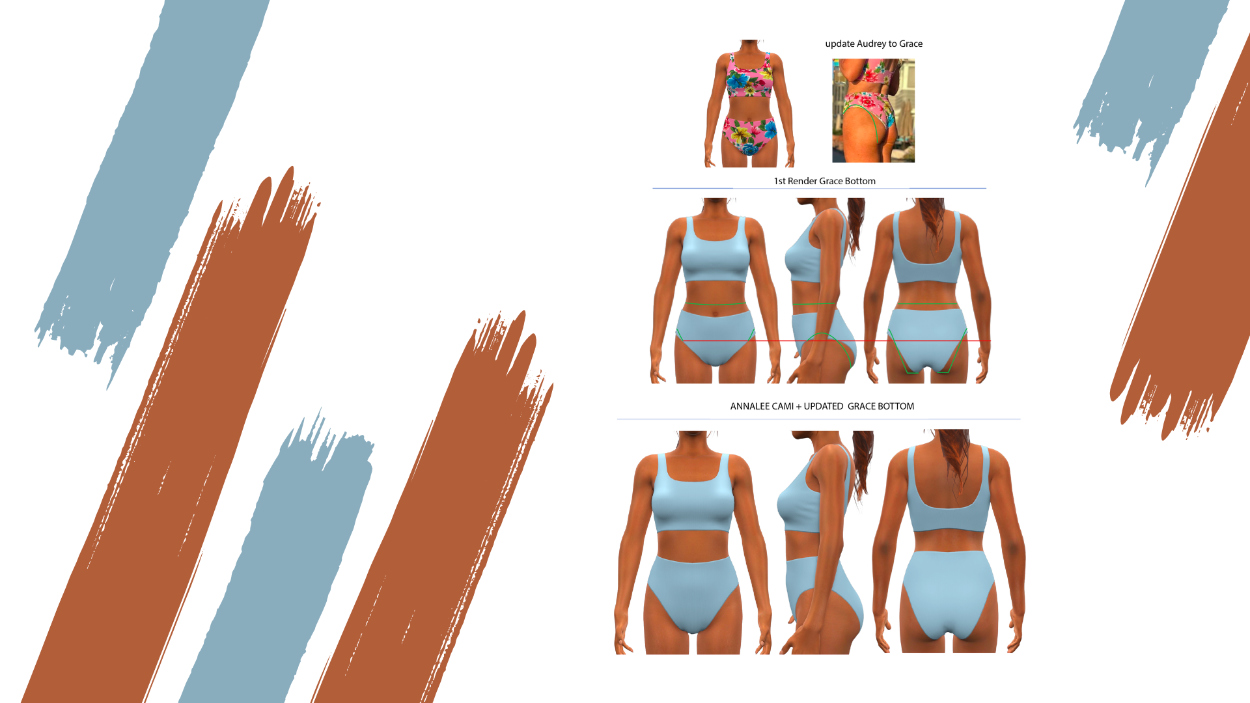

The culmination of JVBswim’ objectives were applied and the integration of traditional craftsmanship and digital technology came to life with the “Annalee x JVBswim ” collaboration. Utilising 3D design , for customer driven production, it allowed JVBswim to present more options to the consumer with minimal overhead while reducing waste. Partnering with mom-influencer Annalee Ford, JVBswim launched a capsule of a “mom-approved” set – a multifunctional swimwear/lounge/athleisure Cami top and just-the-right-coverage high waist bottom. Annalee had initially purchased an original Cami top and high waist bottom from JVBswim and fell in love. We worked together to tailor the set from its athletic contemporary fit to a more “mom-friendly” fit. Development was minimal and streamlined – two rounds of 3D digital sampling and two physical sample sets: one set for fit and the finalised second set for the photoshoot. The storefront featured 3D fit images of all the colorways, with XS-3X sizing available, further reducing sampling waste and enabling the company to capitalise the deadstock’s limited quantities – every order was cut with purchase for production maximisation. This allowed JVBswim to utilise deadstock fabrics in quantities of two yards to 60 yards and lean into the colours and sizes demanded without high overhead costs or waste, receive market analysis, and scale appropriately. With preparation and partnership from our local vendors, turnaround times began at just five business days from the end of pre-sale to shipping. Based on sales, JVBswim was able to lean into high performing colorways and make targeted purchases for seamless scaling. The consumer’s reaction upon learning of the use of deadstock and the zero-waste commitment: “I am only wearing JVBswim now.”

With the groundwork laid for the capabilities of a customer-driven shopping experience, JVBswim focused on the consumer design-driven experience platform build-out. With JVBswim’s goal to bring sustainable swimwear to all women, a range of partnerships developed, beginning with the NIL opportunity and female college athletes in 2022, suiting moms in 2023, and now in 2024, to include all women. With the scope of styles and high-quality, long-lasting pieces, our consumers can grow up with us. The wide customer engagement proves that sustainability and responsibility of companies are being demanded not just by the younger generations, but also resonates with the mature audience as a responsibility to leave a legacy for future generations. By utilising 3D design, we can present options for the consumer berth comprehensively from colours and prints to styles, fit, and design functionality to meet their needs. The wide range of our customers allows us to address what women want as a whole rather than being divided by niche markets. Each undertaking of JVBswim is intentionally building up to the next initiative.

To test the demand for a fully personalised design and shopping experience, JVBswim hosted the JVBkini Bar at Bar Ella, a local women-owned/operated, eras-tour vibe restaurant and lounge. Advertising a “Design Your Own Bikini Bar,” with a single $75 targeted social media ad, network posting, and word of mouth – the house was packed for the entire duration of the event and beyond. The women, aged 21 to 38 years old, sizes from XS to 2X, came in for a personalised design and shopping experience. To design your own JVBkini, participants were presented with a targeted paper design form version of the application in development, where they could choose their desired style, design details, size, and colour from sample swatches of currently stocked deadstock fabrics. The demand was overwhelming , with the number one question being – “Can we do this on your website?” The answer – “Coming soon.”

The dare to dream has taken us beyond where I imagined JVBswim could beIn under two years of launching. ith only an in-house team of two, our network of industry experts, freelancers, and fellow believers have advanced JVBswim from establishing a full production apparel pipeline to development of a consumer driven retail experience via gamified shopping platform – integrating personalised fit on customizable avatars to deliver a design-gamified experience with output of goods both physical and digital to fulfil the customer’s gratification of shopping without waste. JVBswim is the sandbox that we built to play in, and welcome , small brands and mass market partnerships alike to meet consumer engagement and profit margins without filling the landfills. The “Don” of a new era is upon us with JVBswim.