[Featured image: On LigthSpray.]

Key Takeaways:

- Swiss footwear company On this week introduced LightSpray, a sneaker production method that uses a robotic arm to spray a recyclable TPU upper onto the shoe’s sole without glue. This innovation could reduce production time from hours to minutes and use fewer parts than in traditional engineering and production.

- The fundamentals, however, are not new, with various fashion businesses – mostly in footwear – leaning into mechanical innovation, and robotic spraying of different materials being trialled across other segments.

- From a communications and marketing perspective, this is further evidence that performance-oriented brands are able to directly translate their use of technology into consumer-facing communications, while other sectors struggle to articulate the benefits of innovation.

This week, Swiss footwear company On introduced LightSpray: a sneaker production method that uses a robotic arm to spray a shoe’s upper in one go. The upper is made from recyclable Thermoplastic polyurethane (TPU) – a material with characteristics of both plastic and rubber – and is bonded onto the sole of the shoe using thermal-fusing technology instead of the traditional glue and pressure.

On’s innovation team has said that the entire process takes just six minutes (three for the upper alone). This is a significant time-cut when considering that the production time to make an upper can be measured in hours depending on the material and the methods, and finishing the entire shoe can take much longer due to the incorporation of various fabrics, tension wires, stitching, and adhesive. This timeline may be even longer given the current challenges within the fashion supply chain.

On’s technology aims to address that availability and capacity issue, too, as its method uses just seven parts – as opposed to the usual 30-odd – and there is a clear goal to move production from Asia directly into local markets around the world, assuming that this approach is scalable, cost-effective, and portable – all very big assumptions, of course.

From the brand’s own perspective, the purpose of this push into more robotic manufacturing and novel materials is to expedite production, lower impact (a reduction of an upper’s carbon footprint), and allow for a swifter response to trends. “There are no limits to this technology,” says Ilmarin Heitz, senior director of footwear at On. “You can produce what you want, where you want, and only as much as you want”.

As above, there is certainly some wishful thinking at play here; Heitz may be correct that the limits are not technical, but they are certainly going to be economic. Piloting new production methods and new materials is one thing, but making them viable at industrial scale is notoriously hard – with perhaps the most prominent example being the quiet scaling-back of Adidas’s ‘Speedfactory’ vision a couple of years ago.

When we think about the economics here, though, a key metric will be how well these shoes sell, and how successfully the message that mechanical innovation has a direct through-line to user performance is communicated and received.

First: some more on the mechanics at play. From watching On’s “The Secret of LightSpray”, we can see that to create a LightSpray shoe, a robotic arm holds an engineered last and the outsole of the shoe under a sprayer; twisting and turning it as TPU is applied in a helical pattern. This single, continuous string bonds to the outsole and itself without glue. On can then customise the shoe’s stretch, breathability, and support by adjusting the distance between the shoe and the spray or changing the helix’s diameter. The robotic arm then transfers the shoe to another robot for a colour spray, after which the shoes are ready to wear immediately, foregoing the usual delay required for curing.

Such robotic arms, already common in car manufacturing and other industries, and are seemingly not out of reach price-wise for fashion businesses, including those on the smaller side.

And now more on that marketing element. On will unveil the LightSpray technology with a demonstration for media at its On Labs hub in Paris on 25 July, the eve of the Paris Olympics, and the shoes will be worn by world champion runner and winner of the marathons in Boston and New York City, Hellen Obiri.

While this development from On is certainly bold, it is not a fundamentally new idea. The Interline has previously spotlighted NEFFA | New Fashion Factory, who used a similar approach to both material and methods for creating different product categories. NEFFA’s “new fashion factory” comprises of three stages: 3D design, biomaterial creation, and automated, robotic construction. The workflow initiates with design simulations in sophisticated 3D environments, leveraging body data from scans to generate tailored, recyclable, rigid 3D moulds. Concurrently, the factory manufactures innovative materials, starting with the mycelium-based MYCOTEX.

This material, crafted using food-grade ingredients and liquid fermentation, offers flexibility, sustainability, zero production waste, and circularity. In the final stage, digital production combines the 3D moulds and advanced materials, and automated robots apply the biomass directly. This technique improves market speed and sustainability, while mitigating the drawbacks commonly seen in conventional production methods.

While the resulting products from the above process were relatively rigid, we have seen similar experiments conducted with electrostatic binding of sprayed fibres to create flexible garments in the past – both on the runway and in the research lab.

Alongside this, On’s biggest competitors have also obviously been experimenting in similar areas where mechanical innovation becomes a direct line into marketing: Adidas’s Futurecraft 4D outsoles and Strung uppers, Nike’s Zoom Superfly Elite track spikes, and Vivobarefoot’s VivoBiome custom shoes.

We currently see less of this marketing in apparel, despite the prevalence of labels for breathability, stretch, waterproofing and so on – which capture the final characteristics and performance attributes of garments, without speaking anywhere near as often to the method behind them.

For a variety of reasons, both casual and professional athletes are more open to investing in newness at the mechanical level, trusting that it will translate into better performance, comfort, and durability in their footwear.

So while it might not be necessary (or possible) quite yet for clothing brands to embrace mechanical innovation in the same way as performance footwear businesses, it may be worth considering for the long-term. This might include sewbots used for automated sewing and reducing labour costs and increasing production speed; further improvements to automated cutting machines that provide precise cuts for fabrics, and the machine-learning enabled nesting algorithms that feed them; 3D knitting machines that produce garments quickly and efficiently and allowing for on-demand manufacturing; and robotic arms – the benefits already shown in footwear – used in assembly, packaging, and quality control.

Doing so might also provide the competitive edge that brands need given that the retail environment is more capricious than ever. The past few years have seen major brands and retailers struggling to maintain popularity – including Farfetch, Matches.com, Burberry, and Supreme. In the latter’s case, there may be a revival in its future thanks to its recent sale to French-Italian eyewear maker EssilorLuxottica, who has been making moves in technology from working with Meta on smart glasses, to integrating tech into glasses for those with hearing loss.

Before that, however, all eyes will be on Paris – and Ms. Obiri who will be showcasing On’s technology for all the world to see. And depending on how it goes, it might set an accelerated pace for innovation in the footwear and the apparel world.

Best of The Interline:

Kicking off the week The Interline reports on Première Vision Paris AW25-26, one of Europe’s biggest fashion industry stages, with far-ranging debates that spanned the full scope of digital transformation.

Next, the Co-founder of Bold Metrics on creating personalised shopping experiences by generating digital twins and providing valuable consumer data insights for retailers.

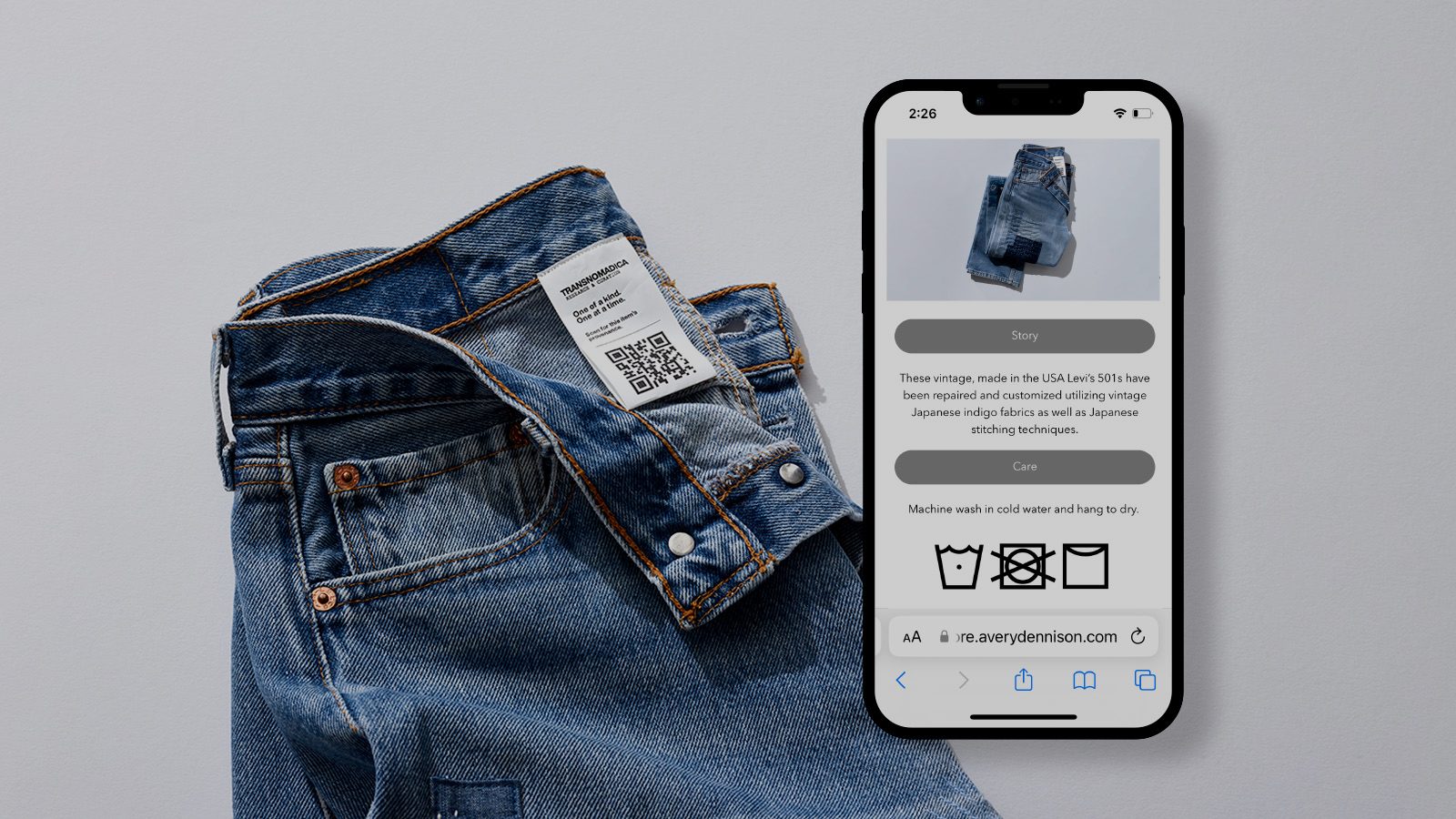

In the first of this week’s podcast instalments, The Interline speaks with the Head of Enterprise Sustainability at Avery Dennison about how the company is working to optimise labour and supply chain efficiency, reduce waste, advance sustainability, circularity and transparency, and better connect brands and consumers.

Eric Hulza redefines corporate leadership in the age of AI; how CEOs and business leaders can balance the cultural evolution and the technological revolution required to deliver on the potential of AI.

Closing out the week, a unique episode of The Interline Podcast, with Andreu David, VP of SOURCING at MAGIC, and our own Editor-in-Chief, documenting the way technology is becoming integral to fashion events, and how those major fixtures are changing to keep pace with the industry’s evolution.