[Featured image: MO/GO]

Key Takeaways:

- Technology startup Skip and brand Arc’teryx debut their MO/GO exoskeleton pants, designed to enhance hiking experiences through powered physical assistance and real-time adjustment.

- This collaboration is an example of the trend towards cross-disciplinary collaboration where merging different industry strengths could create products that offer significant benefits to consumers and redefine market standards.

- Spinnova and Ecco’s leather recycling project and Puma’s textile recycling initiative show the importance of gradual progress in addressing the fashion industry’s sustainability challenges, despite the daunting hurdles of high costs, limited capacity, and regulatory pressures.

A high-tech boost for all: Arc’teryx and Skip introduce accessible exoskeleton pants

California-based startup Skip (a spinoff of Google’s X Labs) and Canadian outdoor apparel brand Arc’teryx opened up reservations of its MO/GO this week: a pair of powered exoskeleton pants that give hikers a boost when tackling hills and mountains. In case you were wondering, MO/GO is short for mountain goat.

The Arc’teryx pants have a lightweight motor at the knee to provide power as the wearer walks, absorbing the impact of each step, boosting the wearer’s legs by 40%, and making the wearer feel “30 pounds lighter”. Skip’s intelligent software also claims to understand how the wearer is moving in real-time and automatically adjusts to any terrain and a walking style that is intended to feel natural.

All this can be yours for the price of $5,000, or $4,500 if you take advantage of the Early Bird Discount. A more affordable and accessible option is to take the pants for a test-walk up “a mountain of your choice” (currently only in Western US and Canada) for $80.

While this may well be the world’s most accessible exoskeleton, the technology is not new; their development stretches back to the 1960s. In the Handbook of Biomechatronics, exoskeletons are described as “biomechatronic devices coupled to the person’s body (a “wearable” robot)”. They are usually made from a structural mechanism with joints and links, which is worn by the human user. The US Department of Defense became interested in developing the concept of a powered “suit of armour.””

More recently, major companies like Ford and Siemens have taken interest in building the technology out, with a view to augmenting human capabilities in industrial scenarios where pure robotics are not the optimum approach. But this is the first time that a consumer outdoor brand – the trendy Arc’teryx, no less, which has made a name for itself on marketing uncompromising performance and innovation – is bringing such a product to consumers.

Like a lot of tech innovations, the journey from industrial applications to consumer usage with exoskeletons has been streamlined through continued investment that has translated into adaptable innovation and miniaturisation. And like a lot of similar journeys, there’s likely to be a tipping point where something that felt like the domain of science fiction suddenly becomes small enough, discreet enough, and affordable enough that it pops up in real-world use cases extremely quickly.

Whether this will prove to be that tipping point is a separate question – the price is certainly high, but not out of the range of what the ‘prosumer’ market is willing to pay for technical gear, but The Interline suspects that we will begin to see mechanical augmentations incorporated into more consumer performance apparel and footwear soon, since this is an area of testing that will likely not find traction with professional athletes whose sports are tightly regulated.

Indeed, MO/GO is already getting a lot of attention from people who are thinking of it in everyday life. A Youtube user commented: “[These pants] Could be a Godsend to me in a few years. Diagnosed with a genetic myopathy and will gradually lose the ability to effectively contract muscles. First thing to go is usually the ability to climb stairs!” But the technology team has made it clear that MO/GO isn’t a medical device. ‘We are not making any medical claims at this time. We are partnering with several leading clinics to develop a related product specifically designed to help people living with neurological conditions, such as Parkinson’s Disease,’ Skip says.

And on the other end of the spectrum from medical use is, of course, the branding opportunity for crossovers between fashion and hard science. This week in an interview with CNBC ahead of the opening ceremonies of the Paris Olympic Games, Bernard Arnault – chairman of luxury conglomerate LVMH commented on a possible crossover between Louis Vuitton and SpaceX. Arnault is open to the idea: “Maybe we’ll see a Louis Vuitton rocket, a collaboration between SpaceX and Louis Vuitton. We have to think about it.”

Whether that wild idea survives contact with the SpaceX CEO’s current personal trajectory remains to be seen, but either way we don’t expect this to be the last time that fashion is brought on as a collaborative partner to create form out of function.

Upcycling waste material: who will win the scalability race?

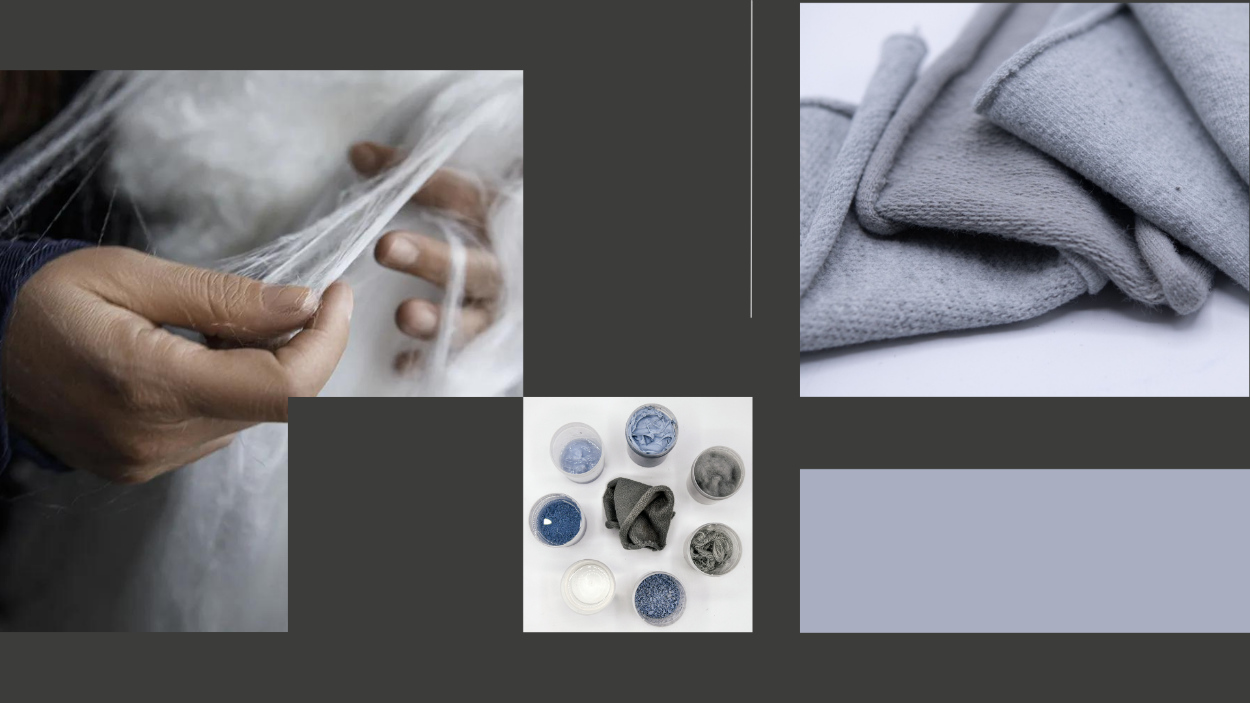

In other cross-industry news, this week Finnish alternative fibre supplier Spinnova and Danish footwear and leather accessories maker Ecco signed a letter of intent (LOI) to advance their joint venture, Respin. The LOI outlines their shared commitment to elevate Respin’s leather waste-based fibre production to commercial scale. A product launch by Ecco featuring the fibre produced by Respin is expected to take place before the end of Q1 of 2025.

Spinnova’s 50/50 joint venture with Ecco and its leather partner, KT Trading, goes back to 2021 to create new, circular textiles made from leather waste. Made with Spinnova’s low-emission technology, the leather fibre’s key sustainability benefits include using renewable raw materials, zero harmful chemicals and minimal water use.

And in a different part of the fashion world when it comes to fibre, sportswear brand Puma is the latest to prove that it is working hard to scale up its recycling innovation. It has recently been capitalising on 2024’s summer of sport to promote sustainable fashion through recycled football jerseys.

Earlier this month, the brand advanced its RE:FIBRE program by producing millions of replica football jerseys containing at least 75% recycled textile waste. The remaining materials came from PET bottles, a source the brand plans to eliminate due to future supply concerns and sustainability goals. Legislative efforts pushing for extended producer responsibility and regulatory scrutiny on greenwashing have made this shift from bottle-to-textile recycling a critical priority.

As with all recycling innovations, and as The Interline has covered before, scalability is the biggest challenge. From a technical standpoint, a lot is achievable. Yet, the primary obstacles include high costs, limited capacity, and the need for tailored processes across different regions. Brands and retailers, whose endorsement is crucial for the adoption of cutting-edge materials, are increasingly budget-conscious and reluctant to invest in unproven solutions. Building the necessary infrastructure from scratch is also daunting, requiring coordination from all of fashion’s stakeholders.

It’s worth noting that RE:FIBRE is labelled as an initiative rather than a technology intentionally. This classification reflects the need for flexibility in scaling up its capacity, allowing for a variety of techniques. Given that even the most advanced solutions are still in their early stages, this approach helps accommodate different methods and innovations as they develop.

Returning to Spinnova and Ecco’s leather recycling ambitions, could this initiative achieve greater scalability success compared to the current challenges faced in polyester recycling efforts? “We believe little steps add up to make a big difference, so we do what we can. One day at a time,” says ECCO Leather CEO Panos Myratos of the company’s ongoing innovation around sustainability. In the face of the fashion industry’s enormous challenges, even incremental progress will be more valuable than standing still.

Best of The Interline:

Kicking off the week, Style3D’s Founder & CEO on leveraging AI to revolutionise the fashion industry by enhancing creativity, efficiency, and digital workflows.

In her latest exclusive for The Interline, Darya Badiei Khorsand asks: can virtual and AI-generated influencers ever truly be authentic?

Jonathan Brun looks at fashion in 2025. What might a radically reimagined, AI-native fashion value chain look like? And how close are we to having an “answer engine” for the industry’s recurring questions?