Manual processes are causing problems during pre-retail logistics for clothing and textiles manufacturers and brands. Ben Balfour, Managing Director of Advanced Supply Chain (ASC), looks at how technology and connectivity can improve efficiencies and strengthen retailer satisfaction.

Pre-retail logistics compliance and challenges

Retailers face a series of pressures, which trickle through supply chains and heighten the demands placed on clothing and textiles manufacturers and brands. Shops, whether online or bricks and mortar, must satisfy consumer expectations for value, quality, convenience and speed. Consumers want the very best prices and to get the most for their money, and with more choice than ever, they realise they don’t often have to compromise.

It’s becoming increasingly competitive for retailers to drive sales and build brand loyalty. This must be achieved against a backdrop of volatile operating costs and squeezed margins, meaning it’s important to optimise efficiencies and productivity. There’s no room for error, delays must be avoided, and stock inventory needs to be delivered to retailers in perfect, retail-ready condition. This quest for perfection is shared and formalised throughout supply chains in the form of supplier manuals and agreements, which will outline Key Performance Indicators (KPIs).

Stipulating terms and conditions for what constitutes acceptable, and excellent, levels of supplier service can seem tough, but can also prove win-win for all parties. If retailers can move products to market quickly, at the right price, they are more likely to keep their customers happy and keep the sales rolling in. Meeting market demand requires a source of supply and sustains the flow of revenue throughout supply chains. However, this revenue chain is proving problematic during the pre-retail stage of logistics, when clothing and textiles stock is prepared and delivered to retailers.

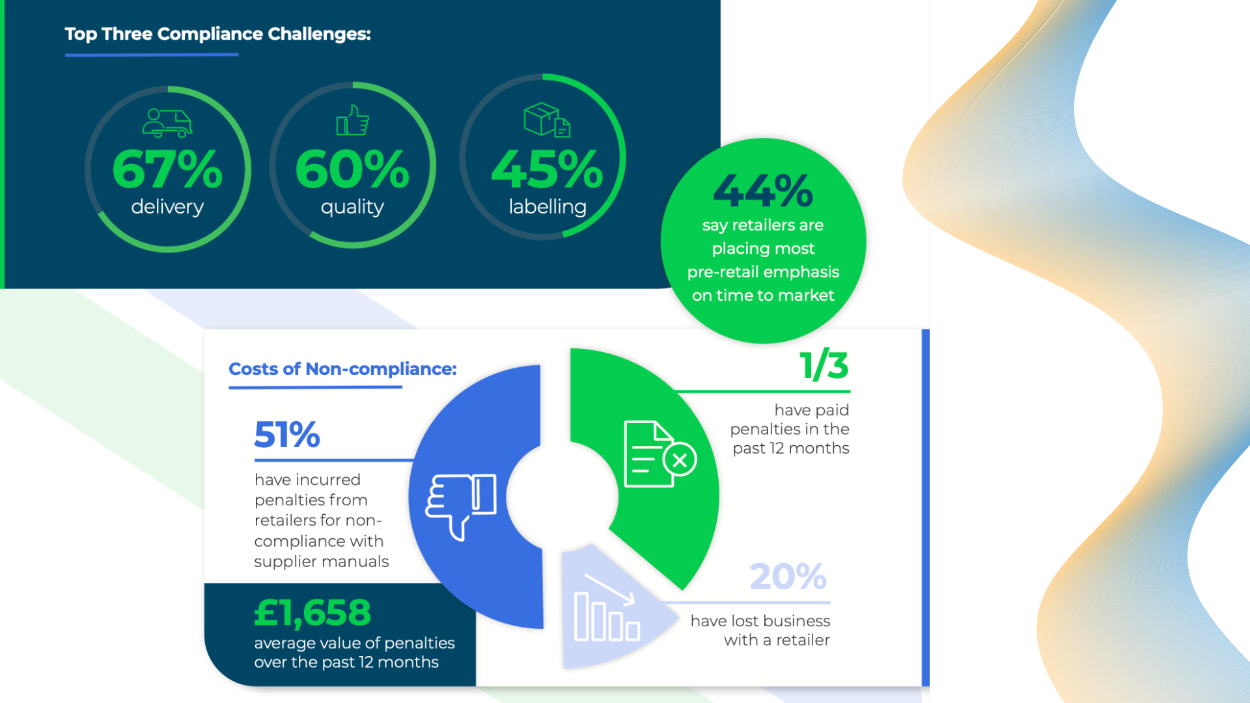

ASC research shows that 50% of clothing manufacturers and brands are failing to meet supplier terms and conditions. Non-compliance with supplier manuals has led to 23% of clothing suppliers losing business with a retailer, with the majority reporting that the value of lost business over the past three years exceeded £75,000. The biggest pre-retail logistics issues are delivery deadlines (67%), quality issues such as damaged products and packaging (60%) and labelling problems (45%).

An over-reliance on manual processes

In many cases, manufacturers and brands are failing to get stock inventory to retailers on time, and in the correct packaging and right labelling formats because their pre-retail logistics relies on hand-written, paper-based systems. There will often be some form of computer and web-based system in place, but processes won’t be fully digitalised and connected. Operatives will be manually filling-in labels and stock inventory logs, because they are physically moving around a warehouse. Information will then be input into a supply chain management system at a later stage.

The reliance on manual processes is inefficient because there’s a duplication of data input and it’s also extremely prone to human error. Hard-to-read handwriting can be misunderstood, with mistakes delaying the movement of consignments and causing incorrect information to be relayed throughout a supply chain. The use of paper-based systems is also a missed opportunity for enriching the flow of accurate, real-time information that can enhance quality control and fleet planning.

Automating on-pack labelling can prove both a simple and crucial step to improving overall performance during pre-retail logistics and pre-retail compliance. Getting labelling right can save time and resource upstream when retailers receive goods, as well as avoiding errors and inefficiencies downstream during the preparation of outbound deliveries to retailers.

The automation and digitalisation of on-pack labelling starts with kiosks in warehouses and fulfilment centres. Labels can be created and printed on demand, eradicating the need for manually writing and filling in forms. As well as making processes quicker, this reduces the chance for errors caused by handwriting mistakes. Labels can be templated, so that they are bespoke to retailer specifications. All the required information can be included and displayed on-pack, strengthening pre-retail compliance and avoiding the need to correct and re-do non-compliant orders. Additional resources and energy incurred through corrective actions can be avoided.

Data-driven visibility

Connecting kiosks to a web-based supply chain management solution enriches the flow and accuracy of stock inventory data. Visibility and insight can be created, which, combined with the right IT capabilities and transport management systems, can be used to improve cube optimisation of fleet vehicles and enhance route planning.

It’s possible to maximise vehicle loads during both inbound and outbound logistics, while also scheduling vehicle movements to reduce dwell time at warehouses and fulfilment centres. Mileage in supply chains and the number of vehicles in transit can be reduced to save carbon emissions and fuel costs. Just-in-time inventory management can also be better planned, minimising stockpiling and the associated energy consumption and costs of warehousing excessive inventory.

Improving quality control

The automation and digitalisation of labelling proves a lynchpin for improving overall quality control during pre-retail logistics. The availability of accurate data can be used to create a quality control dashboard that streamlines product checks and minimises the possibility of imperfect goods moving beyond the pre-retail stage. While this is generally seen as a huge positive for boosting retailer compliance and safeguarding consumer satisfaction and brand reputations, it also avoids effort and resource being wasted in moving non-satisfactory goods backwards and forwards through supply chains.

Eliminating errors and waste and improving performance and efficiencies during pre-retail logistics doesn’t require advances in Artificial Intelligence (AI). It requires an overhaul of widely used manual processes and better connectivity, which can be achieved using technology and software that’s available today. Something as simple as the automation and digitalisation of labelling can positively ripple effect though a supply chain to save time, costs, resources and carbon emissions. It can effectively solve the three biggest pre-retail challenges facing textiles and clothing manufactures to get stock to market quicker, in the right packaging and with the correct labelling.

ASC has created a guide for streamlining pre-retail logistics, which covers five steps for delivering retailer satisfaction, cost savings and eliminating waste. Click here to download the guide.

About the research

Sapio Research, on behalf of ASC, surveyed 200 senior key decision makers with responsibility for pre-retail logistics and compliance. Interviews were conducted online in April 2024 and carried out among key decision makers working for businesses with an annual turnover of £10million+ across the UK.