This article was originally published in The Interline’s DPC Report 2024. To read other opinion pieces, exclusive editorials, and detailed profiles and interviews with key vendors, download the full DPC Report 2024 completely free of charge and ungated.

Key Takeaways:

- Untapped potential in 3D/DPC: Despite widespread adoption of 3D and digital product creation (DPC) tools, many fashion businesses underutilise these assets, limiting their application primarily to marketing or specific development stages rather than integrating them across the entire product lifecycle. This limits potential gains in consumer testing, lead times, and customer experience.

- Holistic strategy and collaboration are key: To maximise the value of DPC, companies need a unified business strategy that incorporates 3D/DPC at every product development stage. This requires adequate investment, understanding technological integration, and fostering a collaborative environment where stakeholders embrace 3D technology. Interoperability and data access remain significant hurdles.

- Investing in people is as important as technology: Implementing 3D tools requires significant change management. Companies must invest in training and support for their teams to overcome the learning curve and integrate 3D into existing workflows effectively. Success comes from choosing the right tools, integrating existing systems, and demonstrating clear wins.

- Building a solid digital foundation: Fashion businesses should prioritise building a robust digital infrastructure, including centralised libraries of 3D/DPC assets, standardised designs, and agile workflows. This foundation enables faster, more consistent processes and supports on-demand production models, minimising waste and accelerating time to market. Clear metrics and leadership buy-in are crucial for measuring progress and maintaining momentum.

Last month, MMGNET and The Interline compiled surveys of over 160 fashion businesses into Fashion & Technology in 2025. That forward-looking report revealed that the most critical challenge for fashion businesses in the year ahead is maintaining profitability and protecting margins – a fundamental business concern that, on the surface, doesn’t have a whole lot to do with digital product creation.

The squeeze goes like this: as consumers demand more value for money, brands and retailers are under increasing pressure to refine their products, optimise the speed with which they make it to market, and adjust pricing strategies and channel allocations to maximise the chances of selling them through without marking them down. This challenge is being amplified by the harsh economic realities of the past two years, including interest rates surpassing the period before the 2008 financial crisis levels and sustained inflation driving up prices across the board. These economic pressures have weakened consumer purchasing power, limited discretionary spending across various categories, and raised costs for raw materials, logistics, and other essentials vital to the fashion supply chain.

So far, so general. But this also prompts the question: how can fashion address the intertwined challenges of efficiency, supply chain disruptions, product-market fit, and risk that ultimately impact profitability and define their ability to meet capricious consumer demand? Is there a single strategic tidal push that can raise all those boats at once?

There might be. The same survey from MMGNET and The Interline also revealed (in a separate datapoint that nonetheless shows correlation) that 3D and digital product creation were both the most popular of three strategic investment pillars for 2025 – beating out spend on AI and sustainability technology – and also the area that had attracted the most investment to date, with close to 90% of fashion businesses either having already trialled DPC initiatives, or having them in-scope for the coming year.

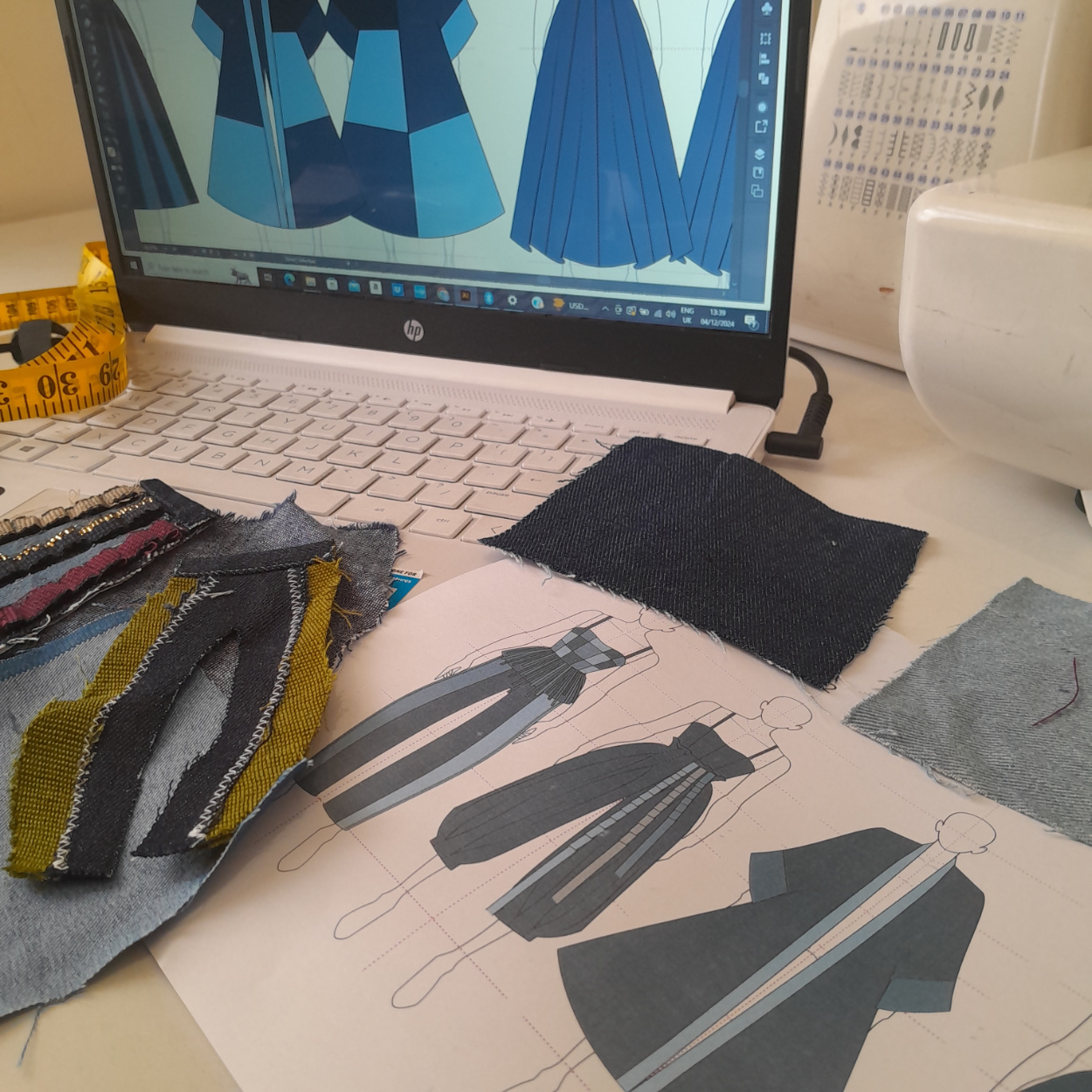

Thanks to that large-scale adoption, and taking account of some self-selection bias given that The Interline’s audience skews towards tech-forward brands, the average fashion company is potentially sitting on a lot of different parts of a solution – elements such as 3D body scans, avatars and digital material captures. But even though the continuous exchange of digital assets and information in other formats – tech specs, moodboards and so on – has become a cornerstone of communication, internally and with external partners, far fewer fashion professionals seem to feel the same way about 3D representations of finished products or their constituent parts.

So while many fashion brands are using 3D assets for marketing, e-commerce, and social media, or – on the flipside – for technical development, few are using the same assets through the bulk of the product development lifecycle.

Or, to put it a bit more simply, fashion, on average, is only making limited use of the assets and tools it has at its disposal.

Consider a brand that uses 3D only for internal visualisation. Their deployment is, technically speaking, a success – but the same company is also leaving on the table the possibility of doing consumer product testing before making final decisions on line plans, and achieving shorter lead times to ensure products better match what consumers want to buy. They’re also passing on the possibilities of doing virtual try-on for improved customer experience.

Strategic clarity and high operational connectivity

To be clear, the emphasis here is on achieving the full potential of technology because much of the fashion industry is already on board with the use of technology in their business operations. MMGNET and The Interline’s research has shown that north of 90% of fashion professionals believe technology is essential or quite important to the effective operation of their business today, and will be for the future progress of the industry.

And this is an opinion shared by senior leaders in the DPC space within fashion brands.

“To really make the most of DPC assets, companies need to take a more holistic approach,” Johnny Mejia, Lead of Digital Product Creation and Visualisation at Champion told me. “In my 10 years of experience, I have seen companies only look at DPC as a fragmented approach to solving specific initiatives, for instance DPC only for e-comm, only for early prototypes, etc. As a result, the vision and the collaboration across all functions gets lost and DPC can suffer the fate of being a ‘nice to have’.”

How to avoid this fate? The short answer: building out an end-to-end digital workflow. “Before companies commit to incorporating DPC, there must be a unified business strategy, that means using 3D/DPC at every stage of product development,” continues Mejia. “[There also needs to be] adequate investment, an understanding of technological integration needs, and most importantly an understanding and willingness by partners and stakeholders to embrace 3D technology as a tool for creativity rather than a barrier.”

But while the potential use cases of digital assets are incredibly broad, there is still a major hurdle when it comes to interoperability and how well the format and purpose of individual objects aligns with practical needs.

This issue affects internal department collaboration as well as supply chain partners – where challenges include centralising and providing live access to product data, a lack of visibility and accountability due to communications occurring outside of established systems, and difficulty aligning different stakeholders around a unified schedule.

There are also instances where manufacturers and material suppliers that have adopted technology strategies find that their brand and retail counterparts are either unprepared or unwilling to adopt similar approaches – and vice versa. A common example is when a supply chain partner has invested in a particular 3D simulation/visualisation technology for creating accurate virtual samples – only for brand customers to continue requesting multiple rounds of physical samples.

This leads to a common fork in the road: the need to determine the use case for a digital asset before creating it, or at the very least before building the different types of scaffolding that will support it.

Thoughts from Dominic Sluiter, whose career includes almost a decade working in 3D/DPC at Nike, co-founding STITCH 3D (a digital fashion startup backed by PVH Corp), and co-founding EnhanceThat – a company that works with fashion companies to simplify and optimise their 3D/DPC workflows. “Choosing between speed and quality is crucial because each path requires a different setup, investment, and set of priorities. Clear priorities and fewer distractions are what drive the most impactful DPC strategies.”

Investing in technology means investing in people

“For companies to invest in the implementation of 3D tools as a part of their digital transformation, they also need to invest in their people,” Janette Cox, VP Digital Product Creation and Technical Design at High Life LLC told me. “The change involved in using 3D tools is immense and overwhelming for all, as it often [comes] on top of day jobs and meeting deadlines.”

Cox explained that while her colleagues appreciate the concept and value the results of incorporating digital tools into their roles, they often feel uncertain about where to begin. This makes it easier for them to stick with traditional methods because adding 3D to their already full workload feels like another task.

“People need ‘white space’ carved out of their schedules to train, learn and engage,” Cox says. “I have seen very positive results when this is achieved: not only do you start to reap the benefits of seeing change using 3D tools, you also start to see an enthused and newly energised team due to the investment made in them. This investment will enable you to scale your digital journey.”

Success, from this vantage point, is also not about acquiring the latest technology – it’s about choosing the right tools. The technology chosen by fashion businesses should support strategy closely and result in demonstrable wins – making it easier for people to get on board. By focusing on integrating and automating the tools already in use, companies can keep users engaged and make the best out of the workflows in place.

Setting up a solid digital infrastructure

To maximise potential, I recommend staying laser-focused on your goals,” says Sluiter. He also swears by brands laying the right digital foundation in advance, rather than working backwards from a finished asset and attempting to figure out where it can add value. “With every team I work with, we spend the most time building the foundation, after answering the big questions about priorities and balancing speed versus quality.”

Part of this foundation includes building libraries for everything – stitched up base designs, modular blocks, materials, trims, avatars. Everything that can save time and promote consistency in the design process. “In today’s fashion industry, speed is essential. The more you standardise and define upfront, the faster and more consistent your workflows will be,” Sluiter continues. Another essential component is designing smooth and agile workflows, as these define success with the users and therefore the overall business and digital ecosystem. It’s also not only about optimising the work itself, but about minimising the time it takes to learn the new 3D workflow. Once this is in hand, inviting leadership teams from all departments for a hands-on experience is a worthwhile investment. DPC strategies can transform the entire company, and it needs buy-in from every link of the value chain.

A brand that feels like it’s getting this all right is M.O.T The Label, a Lagos-based ready-to-wear fashion brand that specialises in affordable, functional and fashionable pieces for women around the world. Founder Mo Agusto launched the brand in 2019 after “noticing a gap in the market for brands that cater specifically to black and brown women, especially ones like herself who have unconventional body proportions” M.O.T. The Label’s website details. At the heart of their operations is an innovative on-demand production model that allows the company to provide a seamless and instant direct-to-consumer experience, while minimising waste. Their operations also have a key component of that digital foundation: libraries.

Omobolanle Adeosun, Product Development Lead at M.O.T The Label told me that M.O.T is building a centralised library of 3D/DPC assets as well as equipping their team with the necessary skills for product development and to build out technology solutions for their team, external partners, and their customers. And one of their key motivations is minimising waste as well as faster time to market. “Distance is no longer a barrier or cause for delay, as samples no longer need to be physically shipped,” Adeosun explains.

Measuring progress to accelerate success

The final piece of the puzzle for fashion businesses to use digital assets to their full potential and for them to reap the benefits in doing so: all sides of the fashion value chain must demonstrate a mutual understanding and a shared vision for what constitutes business-wide progress.

“For example, if your goal is to speed up design, measure your baseline and show how every change improves it,” says Sluiter. “This approach matters because the journey is long, and you’ll face waves of frustration and resistance. The proof you gather – data showing progress toward your goals – is the wind in your sails. Without it, you risk being steered by feelings and frustrations rather than staying on course.”

Cox is in agreement: “Ensure you have senior leadership sponsorship and a clearly defined roadmap denoting what success looks like. Sharing this with your entire team is critical so that everyone understands the journey and is updated regularly. This investment will expedite your implementation in 3D technology ensuring your goals and initiatives are achieved by all.”