This article was originally published in The Interline’s DPC Report 2024. To read other opinion pieces, exclusive editorials, and detailed profiles and interviews with key vendors, download the full DPC Report 2024 completely free of charge and ungated.

Key Takeaways:

- Manufacturers are embracing DPC to streamline sampling and production processes, leading to significant cost and time savings. Interloop, for example, has seen a reduction in lead times and an increase in sample creation capacity thanks to DPC.

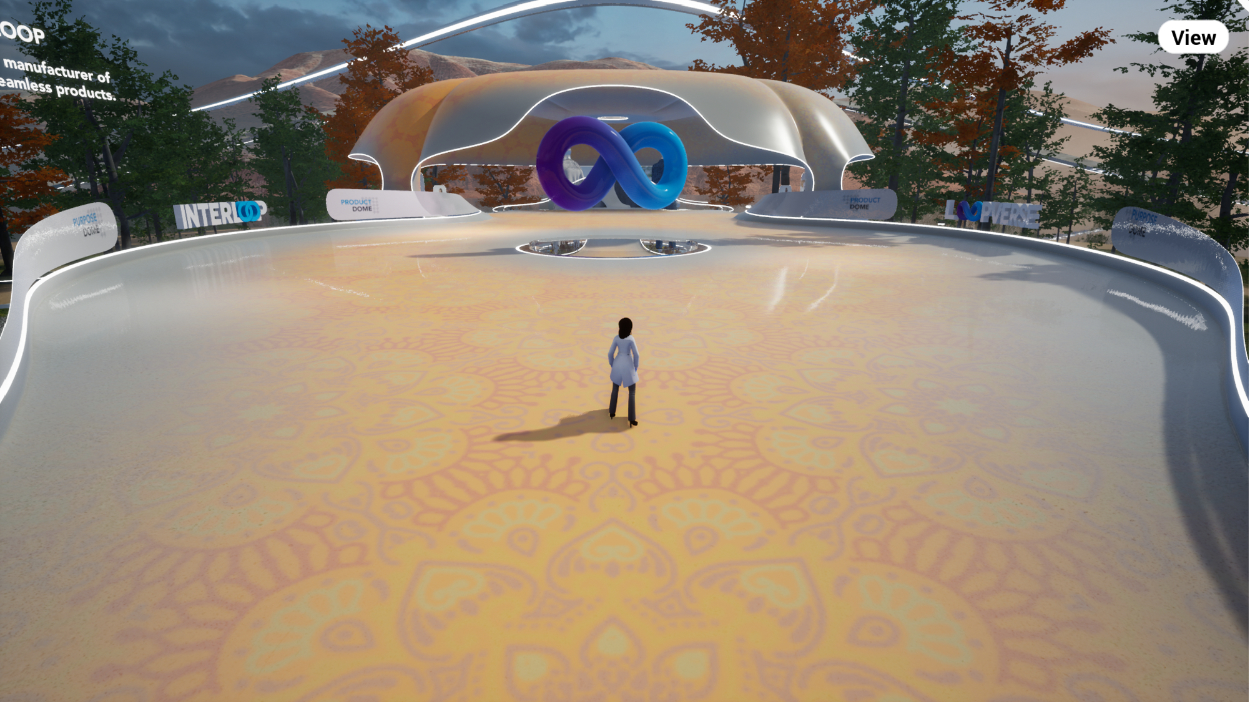

- Digital showrooms like Interloop’s “Loopverse” are transforming how manufacturers showcase their capabilities and collaborate with brands in virtual environments. This immersive approach allows for real-time interaction and a more engaging experience.

- The industry is moving towards a future where DPC data seamlessly integrates with various manufacturing machines and processes. This interconnected ecosystem, powered by digital twins, promises to optimise efficiency and accuracy across the entire production lifecycle.

- While challenges remain in standardisation and interoperability, forward-thinking manufacturers are actively working towards a fully digitised production process, from yarn selection to garment washing. This comprehensive vision extends beyond individual samples to encompass the entire factory, offering brands unprecedented visibility and control over their supply chains.

Fast fashion manufacturing is a sample-intensive process. Before a product reaches the point of bulk production, the designers’ vision is brought to life in a series of collaborative steps that each require back and forth communication between the manufacturer and the brand.

This process consumes time as a primary resource, but every sample also has its individual cost in terms of fabric, trims, labour, and shipping. The primary goal, of course, is a product that the designer and the brand customer is satisfied meets their original intent, but for any improvement made to the sampling process – especially any reduction of the number of samples required to fulfil the brief – the biggest beneficiary is actually the manufacturer. The sooner a product is ready for mass production, the better prepared that manufacturer is to make it the best it can be, as efficiently as possible.

This is why 3D and digital product creation have become so important to the fashion manufacturing sector. The ability to shorten the distance between the original intent and a production-ready sample is incredibly valuable – and leading manufacturers have invested in not just growing these capabilities, but building out the technology ecosystems and the in-house talent to be prepared to stay ahead of the expectations of our brand customers.

At Interloop, we see DPC capabilities as being the essential levers that help us to adapt to changing global dynamics, and as opportunities to translate our many different centres of expertise into compelling offers for leading brands who have their own digital transformation strategies.

For those brand customers – especially in fast fashion – the right manufacturing partner is the partner that has invested in ways to make the process of sampling and production as lean as possible. And in our experience DPC has proven itself to be the best possible way of reducing sampling load, collaborating more closely with our customers, and finding new ways to achieve that lean target.

From our perspective, investment in DPC has delivered a clear return that we and our partners can directly measure: as a company we are able to increase our capacity to create samples by making as many of them as possible digitally, and our customers can use those digital samples to evaluate designs and make necessary changes, which contributes to a reduction in lead times.

Digital Showrooms are a great place to show a collection in a virtual space. Users experience is great for shoppers to see and virtual try-on a garment before purchasing. At Interloop “Loopverse” was created with the same vision. Our designers create a collection each season to show our capabilities to our customers in a victual space. We can have a virtual meetings where our avatars interact with each other. Able to speak and interact, Staying connected through experiences. A virtual 3D space to showcase our digital capabilities and a brief profile of Interloop. The architecture was designed inspired by a cotton flower. A world was built around with 2 domes. 1 space dedicated to 3D outfits and the other for a brief interloop company profile. QR codes are added at multiple locations to see an Augmented version of an outfit.

As a key manufacturing partner, we have also positioned our drive towards DPC as part of a more complete digitisation of the whole manufacturing process. In practice, this has allowed us to bring a similar mindset to every part of production – with samples being just a small part of a bigger picture. Across this transformation, we also relied on adoption of the same workflows from our customers, and while most of them quickly realised the value of collaborating digitally, others needed a little bit more persuasion – and a deeper demonstration of the capabilities of DPC.

To demonstrate those capabilities, we would always walk through the traditional fashion production process before comparing it to the digital alternative – not just as enhanced by 3D and DPC tools, but with other new technologies and new techniques applied to it.

Usually, the process of manufacturing a new product would start with a customer sharing a tech pack over email. Instead, what if their designer’s sketch was instead converted into a photorealistic picture using AI? Designers could then evaluate their silhouette and decide if this style is good enough to proceed to the next stage. Then the tech packs can be uploaded to a PLM, with auto generated email sent to the vendor requesting a sample and a price. That tech pack is then downloaded from PLM, assigned to designated 3D designer at the manufacturer’s end, and the finished work is uploaded to the same platform.

In place of iterative sampling we have a much shorter timeline to alignment, a much closer bridge between brand and manufacturer, and a host of other benefits that also come with making DPC the foundation of the design-to-production lifecycle.

Vendors, for instance, can use a digital library (either as part of a PLM or as a supplemental solution) to download digital raw material like fabrics, trims, pattern to make a 3D sample, and then upload this back to the same platform. This digital material can come from the customer, but ideally raw materials are digitised by the material supplier – including fabrics, trims, and threads – so that the whole industry shares a common reference point in 3D, making it the new norm.

At Interloop we are also working to take the practical applications of that common reference point even further, where we make use of 3D and digital assets to enable machines and solutions to talk to each other. Data from our Jenologia laser machine can be imported into CLO and exported back to the machine directly for physical samples.

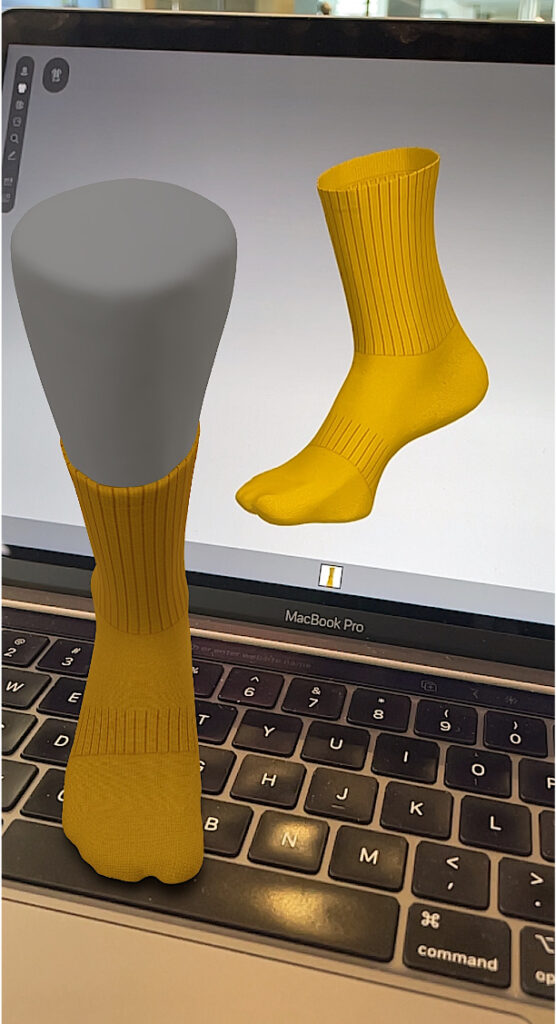

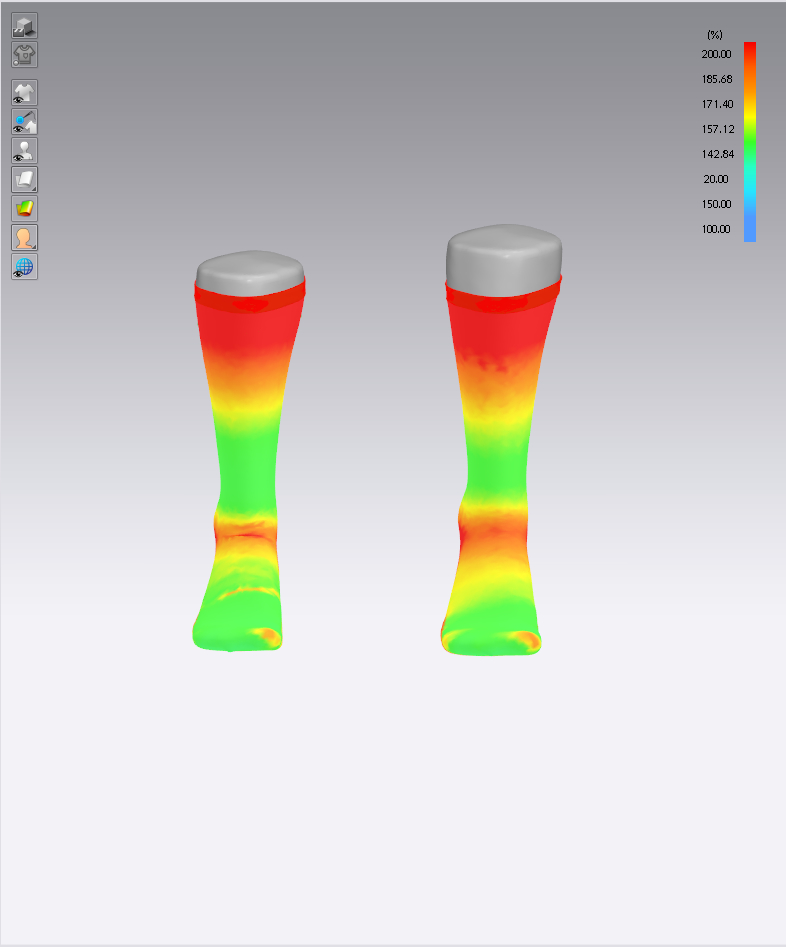

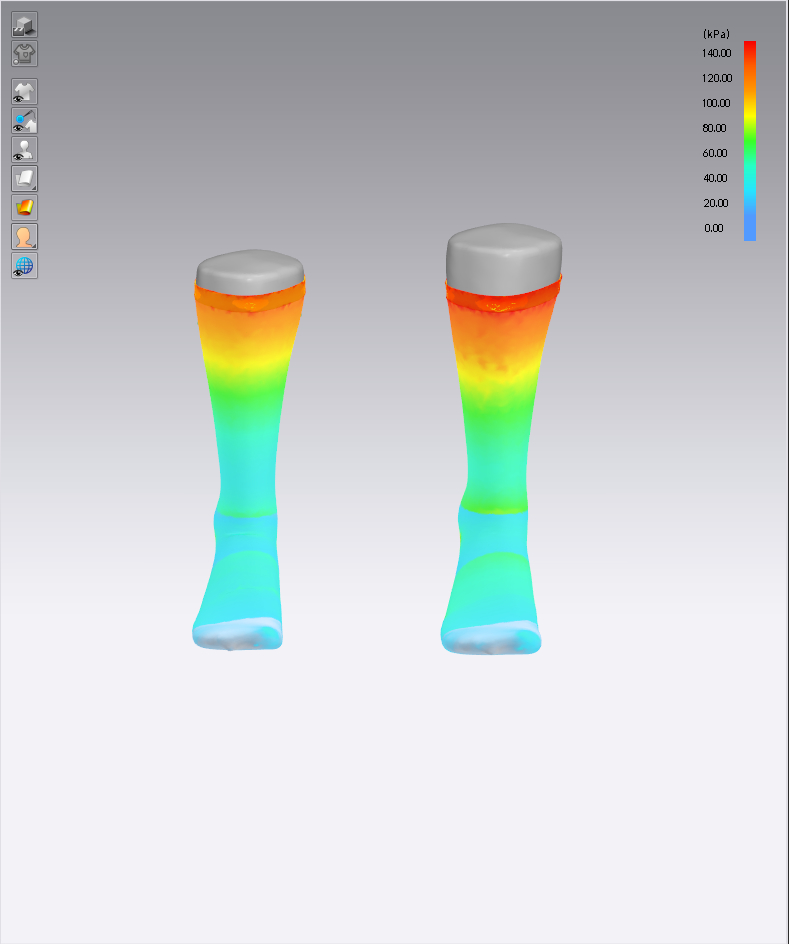

Another example is Shima Seiki, which allows us to select a digital yarn and conduct digital knitting within the software – including selecting the gauge. As well as being the connective tissue between the manufacturer and the customer, DPC data can also go directly to knitting machines. As we have tested the limits of DPC even further, we have also begun pushing further towards the vision for a comprehensive digital twin that exactly mirrors the physical: the behavior of the fabric stretching, the drape and, crucially, the fit of a style (which we can simulate using stress and strain maps) is all also the same across the physical and the digital.

As you may already be thinking: this is a lot of trust to place in a suite of technologies. This is true, and this is also why we believe in the development of DPC standards. Just as we have standards for physical samples, the fashion industry needs to be able to rely on digital baselines and frameworks that allow us to standardise the 3D process. Crucially, those standards also need to work to lower the barrier of entry for everyone, so that we, as manufacturers, can meet the market’s needs – not just in good quality bulk production, but as partners with expertise across the full spectrum of digital product creation.

Virtual FIT test can be done using stress and strain maps within a 3D software but the need is to standardize the results from a recognized authorities which can easily be understandable and recognized by anyone, for example we know what 1CM or 1 Inch means similarly the data showing in the 3D software on stress and strain maps needs to be in a standardized for easy understanding and acceptability with in the fashion industry. Which will result in FIT approvals over digital sample.

But there is still work to be done in reaching this level of standardisation and interoperability. Right now there is a significant need to improve the way different solutions collaborate and integrate, which will be necessary to take multi-stakeholder DPC to the next level.

This is not just a challenge for 3D technology companies, either. If you break down the manufacturing process it consists of yarns, fabric, dying, patterns making, cutting, sewing, trims application and washing. All these processes are managed by different machines, made by different companies around the world, with competing priorities. Each machine runs its own software or mechanical process.

A genuine digital twin would have the power to integrate with each system. Imagine a near-future scenario where the 3D software has the built-in capability to select yarn type, which can be produced to the same exact specifications with a click of a button. 3D software then makes a digital-knitted / woven fabric without scanning any fabric texture, to a specific color. A dying recipe can then go directly to the machine from 3D software. Patterns can be fed into cutting machines that will work with 3D product definitions to maximise the utilisation of fabric. Most sewing operations would be automated, with the type of thread and the length of the stitch being fed from 3D simulation software to machine. Wash recipes would be simulated in DPC to shows how the garment will look after wash.

This is, in many areas, a future vision rather than a current reality, but it remains a vision that forward-thinking manufacturers are already working towards – ready for the wider industry to request it, and preparing to work together, openly, to realise it.

As a further extension of the potential of DPC, the next step for the vendors should be not to settle for digitising samples, and to forge further ahead with creating digital twins of entire factories., to create a digital model for manufacturing that can predict bottlenecks,monitor output, maintain hardware, foresee issues, and create solutions… And if a truly digital, end-to-end production process, can predict exact delivery dates and control the flow of production, brand and retail customers then get an entire different level of digital product creation, with the ability to track orders in real-time.

For suppliers, investing in DPC should not just be a way to make 3D garment samples, but part of a bigger picture, where the entire flow from design to store shelves is digitally transformed. The boldest manufacturing companies are already thinking this way, and building comprehensive DPC capabilities in anticipation of an increasingly digital future.