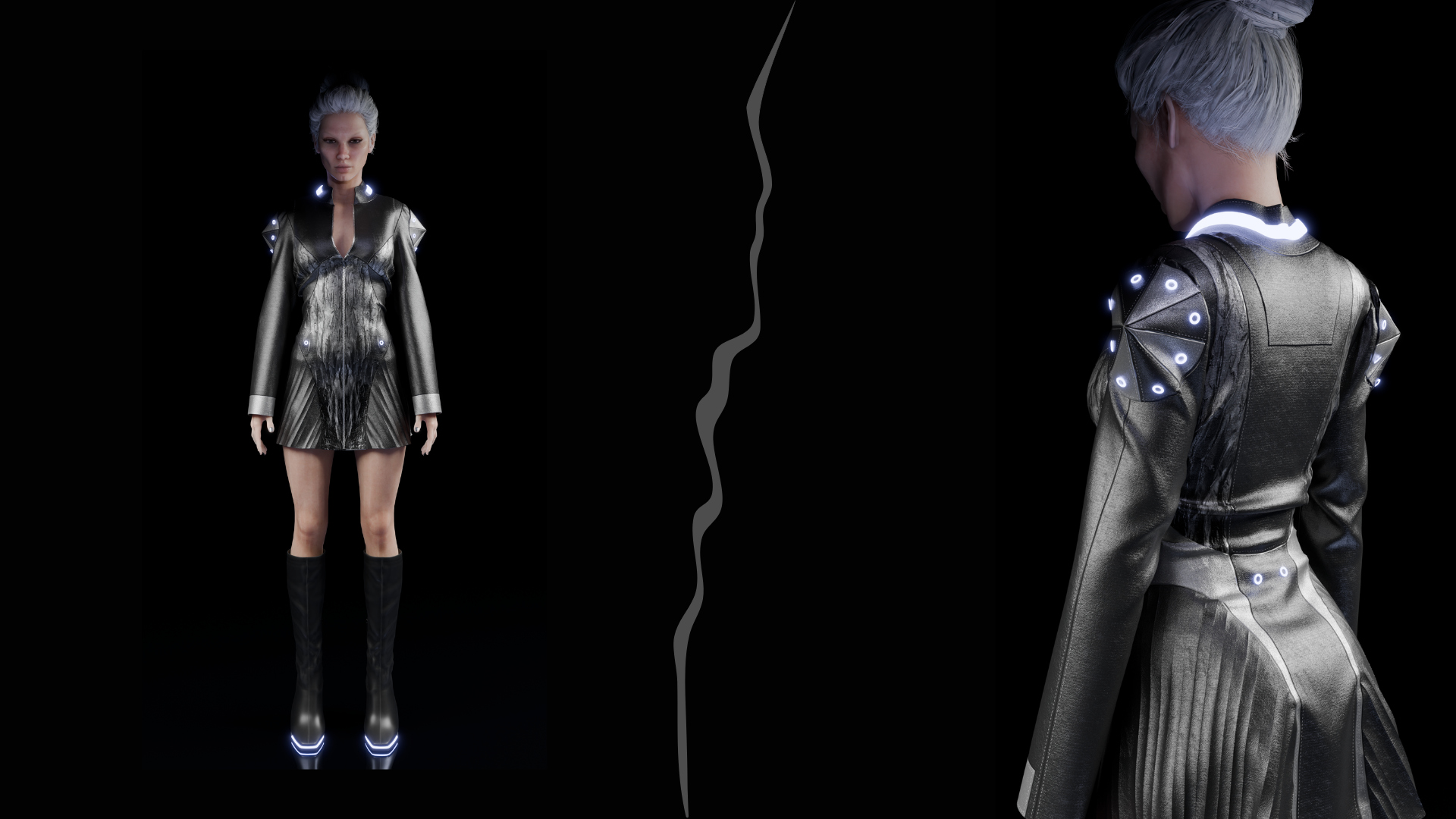

[Featured image: 3D Fashion Solutions]

This article was originally published in The Interline’s DPC Report 2024. To read other opinion pieces, exclusive editorials, and detailed profiles and interviews with key vendors, download the full DPC Report 2024 completely free of charge and ungated.

Key Takeaways:

- Many fashion companies are underutilising Digital Product Creation (DPC), viewing it merely as a tool to reduce physical samples rather than a comprehensive digital transformation, hindering the full realisation of DPC’s potential in areas like marketing, sustainability, and innovation.

- Effective DPC integration requires strategic alignment of resources, targeted training, and a realistic approach to implementation. Prioritizing employee aptitude and leveraging external expertise can accelerate adoption and build internal trust in digital workflows.

- Establishing trust in digital garments as accurate representations of physical products is critical, which can be achieved through continuous refinement, comparing digital and physical samples, and incorporating advancements like soft body avatars and AI-driven design tools.

- Pioneering DPC innovation requires investment in emerging technologies like AI and tactile feedback systems, as well as a willingness to explore new applications beyond traditional product development, such as virtual fashion and digital identities. Companies that commit to DPC now will be best positioned to capitalize on future advancements.

As the name suggestions, digital product creation is about much more than just 3D. It represents a full-on digital transformation of how garments are designed, developed, and brought to market – and it has the potential to positively impact efficiency, sustainability, and marketing, collaboration and the innovation pipeline.

Despite – or perhaps because of – the sheer scope of those possibilities, many companies are only scratching the surface of DPC’s potential due to resistance to change, missing trust, and a lack of strategic direction, sponsorship, and implementation. There is, to put it another way, a big gap between what DPC can do and what fashion, in general, is willing to let it do.

Overcoming that gap is as much of a change management and cultural challenge as it is a technical one. It will involve investing thoughtfully, overcoming internal resistance, building trust in digital representations of physical fabrics, and spearheading technological advancements with the confidence that they will deliver value across the extended lifecycle. The benefits are compelling – apparel brands that move towards 3D can position themselves as front-runners in a competitive industry – but the industry is still in hesitation mode. So let’s dissect why.

(Mis)communicating the message of DPC

Through recent discussions with industry leaders, it has become clear to me that the fashion industry is not fully capitalising on the real scope of DPC.

Companies that develop 3D apparel solutions still tend to promote them as a solution for eliminating physical samples, shortening product development cycles, and saving time and costs, rather than positioning them as fundamental business transformations.

While these advantages are enticing to executives, the message frequently becomes diluted as it filters down to those responsible for implementation – and it may be lost completely by the time it reaches real end users. Apparel designers may struggle to incorporate 3D tools into their workflows, viewing them as additional tasks rather than productivity enhancers, or in other words, a ‘nice to have’ as opposed to a ‘must have.’

Without a foundational knowledge in pattern making or garment construction, these tools can seem ineffective and daunting, and while technical designers and pattern makers possess the necessary skills, they are often overwhelmed by the extra workload that DPC appears to introduce. And the long-running assumption amongst executive sponsors has been that people with traditional apparel design and development skills can automatically become 3D designers, even though the two disciplines are not one and the same.

To maximize the true value of digital product creation, companies need to invest thoughtfully by strategically aligning resources, training, and technology in order to fully integrate DPC into their existing workflows.

One approach we’ve seen be successful is to focus on training employees who show genuine interest and aptitude for the technology from the outset, rather than forcing it onto everyone at once. This increases the likelihood of successful adoption in the short term, and the users who opted to take a back seat are then likely to see their colleagues demonstrating the benefits of working in 3D, and to gravitate naturally towards it themselves.

Outsourcing DPC is another viable strategy. As the market for freelancers and service providers in this space continues to grow, these external experts can help establish high-quality digital block libraries quickly and efficiently, alleviating pressure on internal teams. Again, there is a prevailing sentiment that the only effective way to implement 3D / DPC strategies is to grow all the necessary capabilities in-house, when the reality is that skilled resources are available to deploy from outside the organisation – including in the supply chain.

Considering the rigid timelines of many fashion development cycles, it’s also important to triage and prioritise: not every product may benefit equally from initial 3D development. Creating a true digital twin—a photorealistic virtual garment that perfectly matches its physical counterpart—requires fabric digitisation and multiple digital fit sessions, which may not be feasible within a four-week cycle. Therefore, it may be more practical to utilise DPC for products that are more likely to proceed to production.

Megan Seyler, VP of Design for Women’s Fashion at Mad Engine – which creates “merchandise for anyone and everyone” across private labels, brands, and “influencer celebrity products” – recognises the disconnect between leadership expectations and practical implementation:

To overcome these kinds of challenges, companies must adopt a realistic and committed stance when it comes to DPC. This involves setting clear goals for its use, aligning expectations across all organisational levels, and allowing time for teams to gain proficiency.

Hands-on experience tells us that hesitation around DPC adoption often stems from a lack of understanding or a fear of increased workloads, rather than any intrinsic distrust of the idea of designing and developing digitally. By addressing these concerns heads-on and providing support to the teams being asked to do the heavy lifting, companies stand the best chance of mounting a successful cultural transformation that then becomes the scaffolding for extending the many benefits of DPC throughout the rest of the product lifecycle.

Trusting digital garments to mirror reality

Building trust in digital garments is crucial for widespread adoption of DPC. So many of the benefits I’ve already written about rely on the axiom that the different roles and responsibilities within fashion can all align on the digital garment as an accurate representation of the physical garment. Getting to this level of trust, though, requires time, patience, and a commitment to continuous improvement. By comparing digital garments with their physical counterparts over multiple seasons, teams can refine their processes and improve accuracy, and over time new business units and different product categories can be brought under the DPC umbrella with that base of trust to rely on.

Timberland is an example of a brand that has successfully implemented 3D in their product development process, resulting in reduced physical sampling with the right foundation of trust. As Sylwia Szymczyk, 3D Apparel Specialist at Timberland, recently noted:

The future of DPC, though, depends on advancements in both technology and workflows as well as a cultural shift towards trust in digital representations of physical things. Rozh Roux, Senior Director of Technical Design & DPC at Athleta, believes that innovation must address the tactile limitations of the digital process to bring all those different elements together:

Client feedback has been instrumental in refining these technologies, ensuring they meet real-world needs. Building on this, innovations such as soft body avatars have emerged in response to the general concern over hard surface avatars, offering a more realistic virtual representation of how garments interact with the contours and movements of the human body. The same feedback from a large number of industry experts pressures further innovation – or, to phrase it differently, the more people start to test the limits of DPC ecosystems, the better those ecosystems will become in both a holistic sense and at the individual solution level.

Another potential solution born out of this kind of innovation is the development of tech bodysuits for fit models that simulate pressure and tension points, enabling digital garments to provide sensory feedback during virtual fittings. While hardly widespread today, these kind of bleeding-edge ideas could significantly reduce reliance on physical samples and eventually eliminate the need for physical fittings altogether.

AI-driven 3D garment creation presents another area of opportunity. Software capable of generating garments from simple prompts or hand sketches would simplify workflows – at least in non-technical applications – and improve accessibility. For companies like Browzwear and CLO3D, evolving to accommodate such capabilities is likely to be part of what it takes to remain competitive. Without continuous innovation, they run the risk of more user-friendly alternatives overtaking them.

Who will actually pave the way in DPC advancement?

A crucial question remains: which organisations will actually pioneer innovation in Digital Product Creation? Across a wide spectrum of cultural and technical metrics, there is a lot of ground to be gained, but little clarity on who will – or should be – first across the line.

While many fashion brands are experimenting with different digital technologies, true innovation could come from those willing to fully integrate DPC into their processes and invest in emerging technologies like AI and tactile feedback systems. This can be a difficult pill to swallow in an uncertain economy, but it seems clearer than ever that extracting the full set of benefits from digital product creation will require companies to commit to pushing the envelope.

Technology providers play a crucial role in this evolution. Companies that develop game-changing solutions addressing current limitations will lead the industry forward. Whether it’s through advanced AI-driven design tools or integrating tactile experiences into digital fittings, the innovators in this space will set new standards for what’s possible in fashion.

As has been well-documented in these reports, and in plenty of other industry coverage and analysis, DPC’s value extends far beyond the product development process. Digital assets can be repurposed for marketing, e-commerce, and even participation in virtual fashion markets. Footwear and accessory brands are already utilising digital animations to create engaging content, and apparel brands have the opportunity to do the same – beyond the use of static virtual photography.

The rise of digital identities and virtual environments presents another avenue. Selling garments designed exclusively for virtual use eliminates manufacturing costs entirely, allowing fashion brands to tap into a flourishing market while addressing sustainability concerns. This approach not only opens new revenue streams but also aligns with growing consumer interest in sustainability and digital experiences.

However, achieving this level of integration requires companies to commit to DPC projects from start to finish, learning from successes and setbacks alike. Those with established DPC workflows will have a significant advantage when new technologies become available, as their experience will enable them to adapt more quickly. The idea of “Metaverse fashion” might not have played out the way its biggest proponents hoped it would, but whatever the future holds for digital fashion, the companies that invest in innovation today – especially innovation that helps them build capabilities, tools, pipelines, and libraries of digital assets – will be the ones that push the boundaries of technology and redefine what’s possible. And becoming one of those companies likely means committing to digital product creation today.