This article was originally published in The Interline’s first Sustainability Report. To read other opinion pieces, exclusive editorials, and detailed profiles and interviews with key vendors, download the full Sustainability Report 2023 completely free of charge and ungated.

Key Takeaways:

- The fashion industry’s unsustainable business model requires immediate changes to combat the negative impact of overconsumption.

- Comprehensive digital transformation could offer one pathway to sustainable fashion by enabling fully digital decision-making and data-backed collaboration, as well as unlocking on-demand, localised manufacturing hubs.

Materials waste, poor forecasting, and the limits of traditional manufacturing have created an unsustainable business model in the fashion industry. This is a call to action to make immediate changes and reverse the negative impact of our fashion overconsumption on the global environment.

According to recent findings published by TheRoundup.org:

- The worldwide apparel industry produced an estimated 92 million tons of textile waste in 2022 alone.

- Garment production and transportation account for approximately 10% of global CO2 emissions.

- Conventional clothing production wastes up to 21% of fabric in the cutting process.

- At the same time, 15-20% of clothes are wasted in unsold inventory, and 60% of purchased clothes are discarded after just one year.

The textile industry’s supply chain can only be described as complex, making fashion validation challenging for designers and engineers. But centuries later—many believe there is hope. We are currently experiencing a seismic shift in the demand for increased efficiency and transparency driven by policymakers, materials suppliers, production operations, distributors, and customers. And the industry’s transformation into a vertically organised, sustainable value chain is dependent on digitalisation.

Advancing Innovation In A Centuries Old Industry

Moving forward, in order for companies to compete in the textile industry, they need to leverage the deployment of digital technologies and mission critical data. New-age consumers want sustainably produced products, driving change in businesses’ buying habits to meet such demand. Brands and retailers are already being asked to show how they are tackling climate change, ensuring compliance with social and human rights requirements—not just in their own organisations, but more importantly, for the entire logistics network from fibre to finished product.

Complete digitalisation will change the sustainability and resource efficiency in textile production by making supply chains and production processes transparent and thereby, easier to maintain through cloud-based communication systems. Digitalisation is necessary to unlock on-demand production through localised hubs. This will bring manufacturing back onshore to neighbouring communities and cut the carbon footprint of transporting materials around the globe—better serving customers, designers, and brands, while reducing waste during the design iteration and manufacturing process (VARIANT3D).

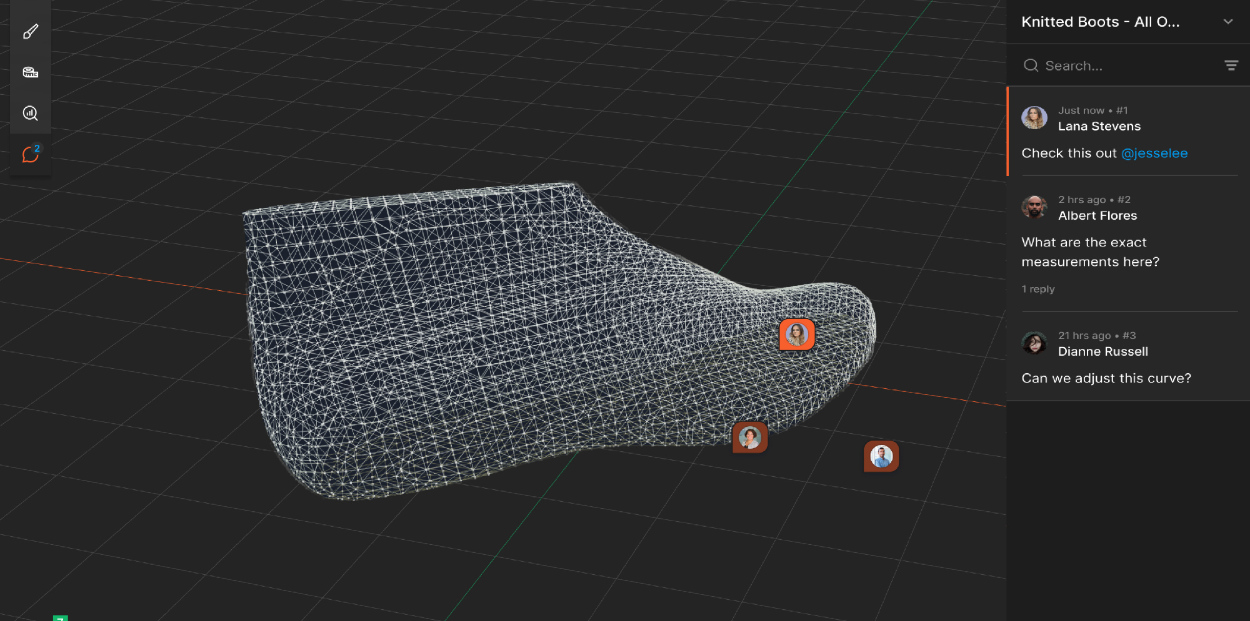

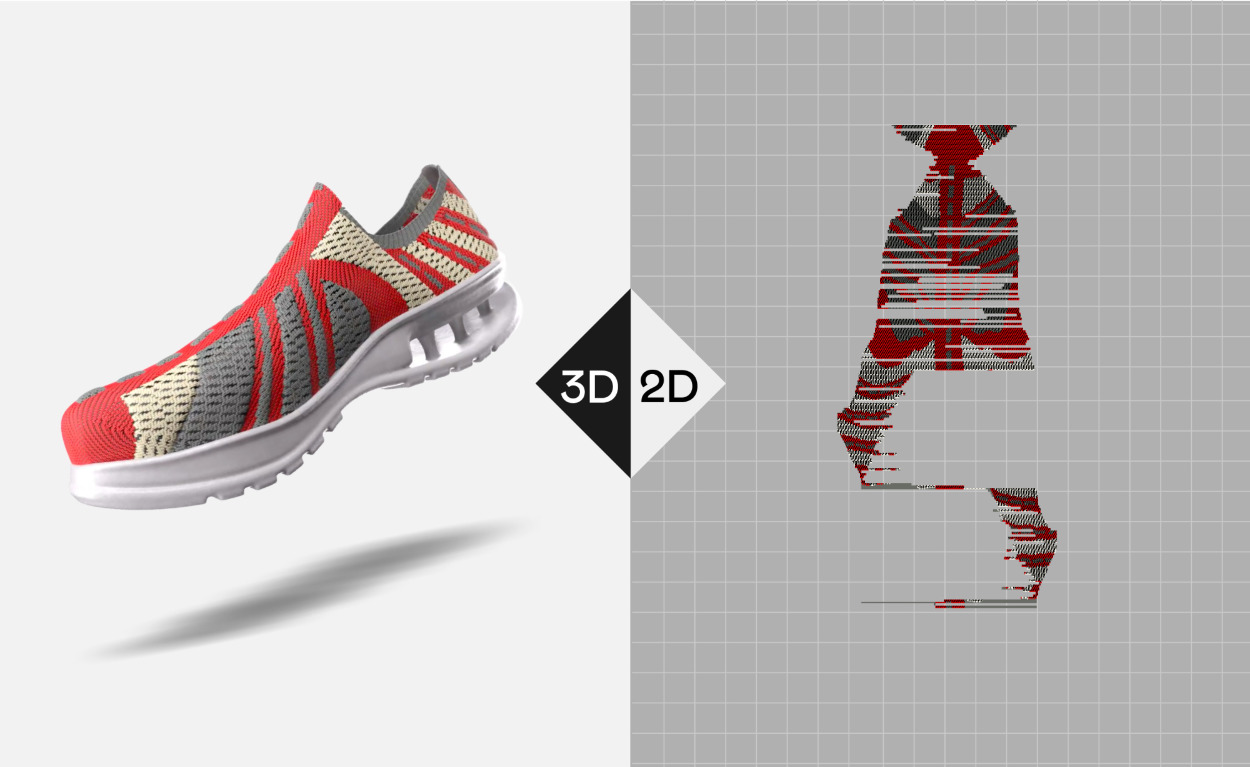

Digital transformation provides an end-to-end solution streamlining the collaboration between stakeholders across the globe, enabling everyone to work together more efficiently and ultimately more profitably. A switch to digital assets means a more automated workflow — increasing accuracy, reducing costs, and accelerating product production. For instance, it enables any 3D model to be converted into knit-to-shape programs, creating virtual prototypes first. Designers can work on creations online, then approve and test them. Virtual try-on technology is already revolutionising the entire shopping experience, supporting customised sizing, colour selection, and on-demand production; benefiting both consumers and retailers. It provides a rich and compelling interactive experience while dramatically reducing waste within the industry.

Examples Of Improved Efficiencies Using Digitalisation

Product approvals/rejections can be performed with the ability to annotate models and relay updates to vendors in real time.

- 3D collections can be presented to prospective customers over the internet and through virtual reality experiences, enabling feedback and sales orders to be taken automatically.

- Drag and drop 3D product models can quickly create collections.

- Carbon emissions can be tracked from sample generation to full production.

Textile technology advances in weaving, dyeing, finishing, knitting, and printing have made fabric manufacturing more efficient, environmentally friendly, and lower-cost than ever before. High-performance fabrics are used in a variety of industries, from home furnishings to sports, medical, automotive, industrial design, structural engineering, aerospace, and art. Employing digital automation in the manufacturing sector utilising these materials could increase annual revenue by $4.9 trillion by 2030, according to an Oxford University report.

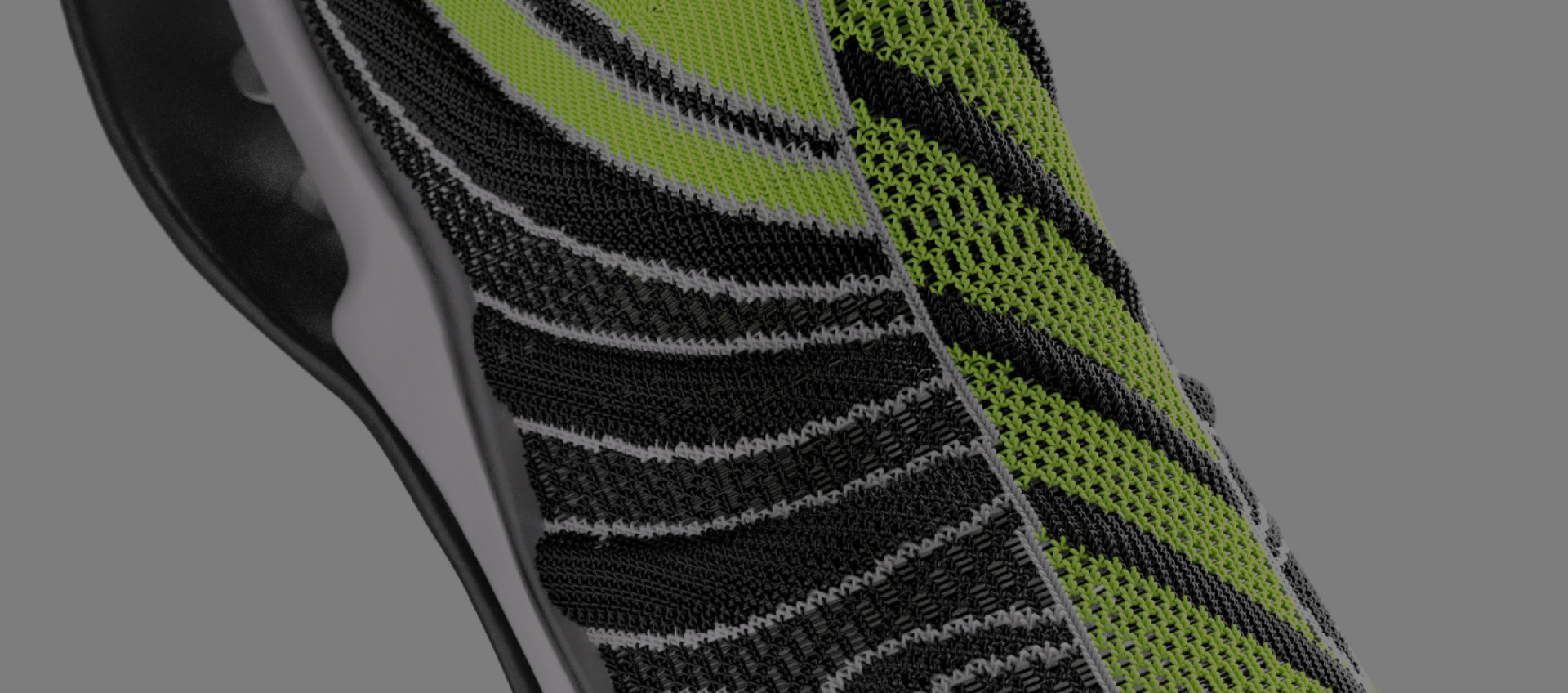

Digital twin technology—the digital reproduction of a physical fabric—is also reshaping the textile industry. By using digital twins, waste is drastically reduced by completing digital design and prototyping processes with high quality, photorealistic digital representations of fabrics. This provides designers the ability to study fabrics before producing products. They can test different colours, patterns, textures, and more without having to actually make physical samples. The result? Decreasing waste, while saving time and money in the process.

The spotlight on sustainability will continue until customers become confident that the products they are purchasing have been manufactured in a fair, eco-friendly, and cost-efficient manner. Sustainable clothing sales are expected to grow from 3.9% to 6.1% by 2026, exemplifying the shift in consumer preference towards such offerings.

Compliance And Transparency Deliver Traceability And Trust

Digitalisation effectively delivers details for transparency—tracking the origin, ingredients, and production processes, as well as transportation routes, i.e., the entire journey of a product. This information is changing the perception and the processes of the entire fashion industry. It is not only the desire for sustainability, it is also the control of costs and margins within the global supply chain that are accelerating the emphasis on resource efficiency and therefore sustainability as well.

The question is not whether it is possible, but whether we understand the critical importance of combining compliance with legal regulations, customer perceptions, and demands to develop sustainable business models. Sustainability in the textile industry is not just a certificate, but an obligation and commitment to responsibility.

The past decade has seen a significant uptick in legislation regulating the fashion industry, ending a long history of self-reporting and self-policing, particularly around its climate impact. In short: going forward brands will be required to increase their focus on emissions reduction, garment worker rights, supply chain responsibility, and product circularity. Legislation is a vital piece of the puzzle, because while grassroots advocacy for change is imperative, government intervention will ultimately mandate widespread change and develop systems for accountability. All required data will need to be compiled using digital tracking.

For the U.S., upcoming legislation could include the Fabric Act, which would be the first federal bill affecting the fashion industry. It will influence brands, retailers, manufacturers, and suppliers. The E.U. and the U.K. are also amping up their legislation to help solve the industry’s notorious adverse environmental impact. The main impetus is to require brands to clean up wasteful supply chains. The E.U. Green Deal was approved in 2020 as a set of proposals to improve policies in line with greenhouse gas emission targets.

Global companies are at risk of being regulated by multiple international, national, and local regulations. “Brands need to be prepared to be 100% transparent and willing to change,” said Samata Pattinson, CEO of RCGD, a global sustainable advocacy agency that works with fashion brands to promote sustainability. Pattinson said she believes brands will have to focus on data in 2023, as most of the pending policies will make it necessary for them to collect and submit data transparently.

One way to do this is by using Digital Product Passports—digital representations of physical products authorising the verification and management of product sustainability and circularity across the entire value chain—are an inevitable trend. They share details including data on raw material extraction, production, recycling, etc. Policy initiatives are requiring more granular levels of product data in order to deliver transparency, traceability, and trust. In turn, this will empower businesses and consumers to make more sustainable choices.

Fully Digital Workflows: A Necessity For Complete Sustainability

Digital transformation is not the wave of the future, its accelerating pace is taking place as you read this article. Businesses that are slow to adapt face losing out to competition, or disappearing completely.

At the Sustainable Textile School (Chemnitz, Germany) in 2018, the pioneers of efficient and sustainable supply chains presented their business models and vision of a connected world managing data for sustainable impact on the environment, people, and businesses. To establish a sustainable and circular textile industry, they indicated future textile professionals would need to understand and capitalise on all the possibilities of going digital to save costs and more crucially—resources. Only in this manner can the world’s oldest industry be fundamentally changed.

As more people become aware of these advancements, the fashion industry will be forced to be accountable in creating sustainable options that minimise its impact on our planet. In a rapidly evolving landscape, embracing innovation and digital transformation within the supply chain is driving impactful change. Companies that adopt this new approach to ethical production are poised for remarkable growth, while those reluctant to adapt may find themselves eclipsed by the forces of innovation.