Key Takeaways:

- DPC and digital assets can make a tremendous difference and enable brands to capitalise on the craft, expertise, and proximity of domestic manufacturing, at the same time as drastically reducing the time, waste, and cost penalties associated with excessive sampling.

- There is still an attitude shift needed by the UK’s big brands and retailers to proximity sourcing, as much of the negative impact of sampling and production overseas can be solved by working closely with partners using DPC and other digital tools.

[Featured image provided by Fashion Enter]

Having worked in the fashion industry for over 35 years I have seen some dramatic changes to the way the industry operates, and what it prioritises. But the last 12-18 months in particular have been the most transformational in the fashion and garment manufacturing space, because they have prompted a complete re-evaluation of many different aspects of fashion all at once.

First, it’s important to understand the vantage point I’ve had on both the long-term transformation of the industry and this new, sudden shift.

As the CEO of the UK social enterprise Fashion Enter Ltd, I saw (and was part of) the garment-making heydays of the so-called “Fast Fashion” era, where our production teams were making up to 30,000 garments a week. In retrospect this was obviously bad news for the planet, and the fact that this model of manufacturing is behind us – at least domestically – is progress. But the alternative side of the story is less positive: for the garment manufacturing sector, the shortfall in demand has made it hard to keep the machines running, the bobbins filled, and people employed.

There are a whole host of conflicting statistics with regard to fashion’s status as potentially the second most pollutive industry on the planet, but there are some figures that we can rely on. The UK Fashion Industry is worth £5.78 billion ($7.25 billion USD) (according to Statista) and is set to grow to £10.8 billion ($13.7 billion USD) by 2026. These seem like encouraging numbers until you start to unpick what happens to the value generated:a £30 purchase in the UK leads to an average cost of £20 return for the brand (NRF, Roland Bergeer) of which 27% is landfill – a total estimated value of £140 million that gets thrown away every year

But what do these growth and waste statistics have to do with the downturn in demand for domestic production? And what does this all have to do with 3D and digital product creation?

One of the most wasteful areas I have seen during my 35 year career is sampling! It honestly drives me mad. But there’s much more to it than just personal opinion: fashion has a clear sampling problem – one that has a huge impact on speed, sustainability, cost, and overall efficiency. And one that the industry has largely abstracted away by shifting to an offshore, high-volume production model, trading carbon footprint for low-cost, mass-scale iteration.

In fact, this sampling culture has, I believe, been one of the foremost contributors to the decline of onshore manufacturing. By moving the process out of sight and out of mind, brands have grown accustomed to requesting multiple sample rounds and scarcely thinking about the cost… or the waste. But when sampling takes place closer to home, and the scale and cost (an average of £300 per sample, in our experience) become more obvious, the delays, the waste, and the inefficiencies of even great-quality samples produced from beautiful fabrics start to become overwhelming.

But as almost every brand now realises, sweeping the sampling problem under the carpet by pushing it offshore is not a long-term solution. Today, most brands and designers are facing the need to radically improve their speed to market, and to drastically improve the sustainability of their operations. And this is where attention is turning, again, to domestic manufacturing – whether that’s here in the UK, in the US, in Europe, or in any local market where clothing is sold.

This is where digital product creation and digital assets can make a tremendous difference and enable brands to capitalise on the craft, expertise, and proximity of domestic manufacturing, at the same time as drastically reducing the time, waste, and cost penalties associated with excessive sampling.

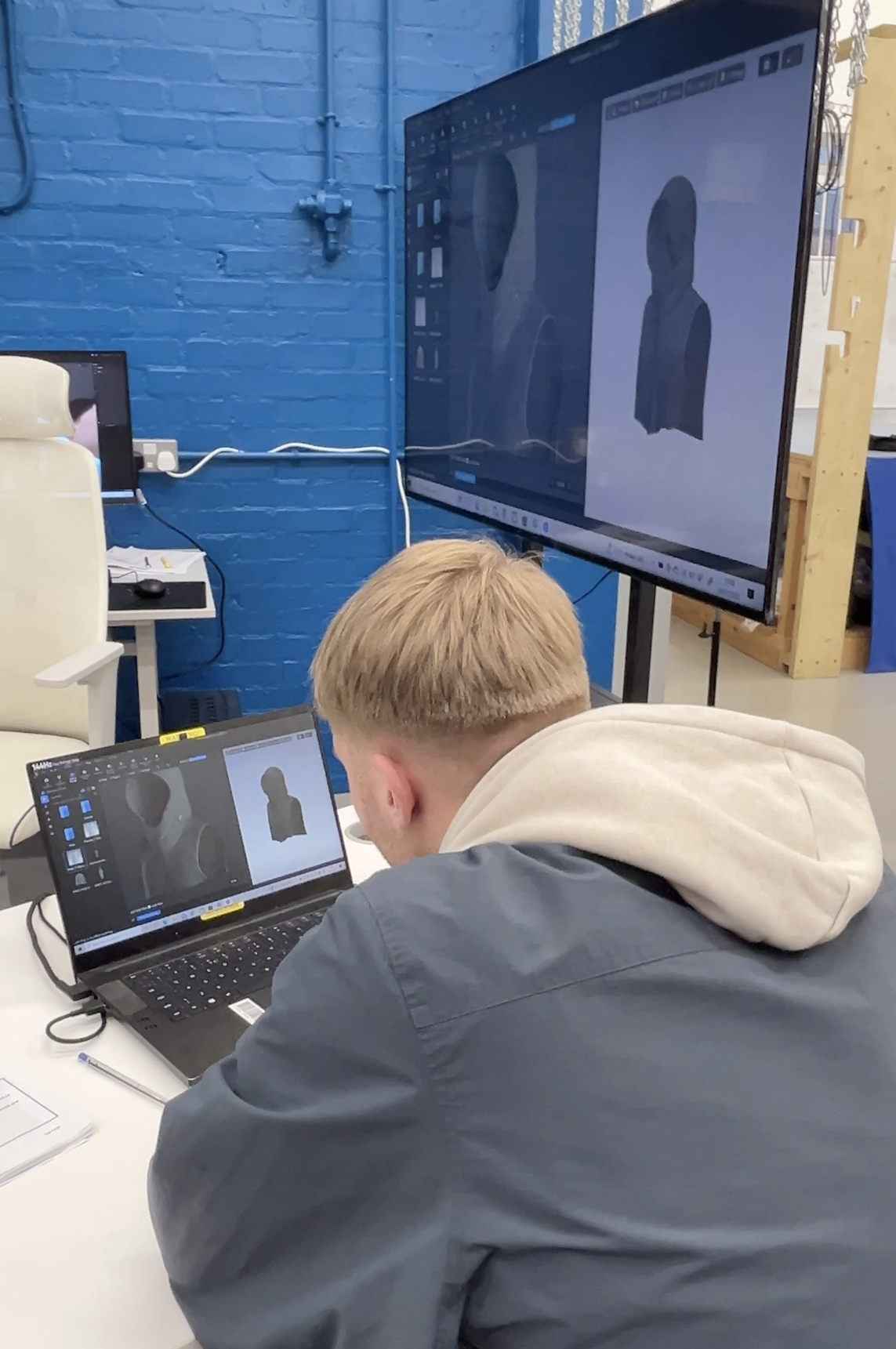

And we know that from first-hand experience, because the team at Fashion-Enter has spent this year really figuring out how to blend technology and tradition across our Fashion Studio and our main factory. We have been using a host of different software and hardware to improve the accuracy of our internal fit, and we have built two different teams of pattern cutters: some that use technology in a major way, and others – our highly talented and much-respected traditional pattern cutters – that create by hand.

Based on our experience, there’s going to remain a demand for both skillsets, whether they exist separately or in hybrid teams. This is something we’ve learnt based on our internal experiments, and it’s also something that our clients have requested – dictated by their own technology maturity, and by their own preferences.

To really prove both the viability of in-country manufacturing and the importance of technology (especially 3D and DPC tools) in delivering it, our North Star in this testing has been a drive towards lean manufacturing throughout the company. This means we’ve been looking at the entire life of the garment, and prioritising ways to extend that life into repairs – which is why we have recently opened a new collaboration with United Repair Centre and Patagonia.

But as you can imagine, the most important part of that lifecycle for speed, sustainability, cost, quality, and creativity reasons is the process of turning designs into prototypes, samples, and finished goods with as few compromises as possible.

So, to optimise those critical lifecycle stages, we ended up creating something of a manifesto for the capabilities we, as a full-service domestic partner, needed to have. And we then mapped these different asks to different tranches of technology:

- We needed to be as responsive as possible to buyers that needed new ideas daily, without sacrificing our own creativity.

- We wanted to reduce the downtime involved in sampling from three weeks to just a few days.

- We needed the ability to have samples signed off by the buyer virtually, before material was ordered and patternmaking began.

- We wanted to standardise our blocks for each client; it was prohibitive to bring in different fit models for different buyers, and the cost of buying 10+ new mannequins was also high. We needed a way to use standardised avatars that were realistic-looking, accurate and flexible enough for sizing, and affordable.

- We needed digital fabrics that behaved with absolute accuracy in terms of draping and other properties, so that we could build trust in virtual samples amongst our own teams and our clients.

- We had to establish a way to then drive sustainable, make-to-order production, bringing together software and hardware that can automate the lay planning process to get the best possible material yield.

On top of all that, we also needed to retain our ethical status, our reputation as being an honest broker, and we as been gigantic.

If this sounds like a tall order – it is! But it’s also, from an industry perspective, essential. And not just for a domestic partner; every vendor that you, as a brand, work with is facing the same challenges and the same demands, and as we worked through this process it became clearer than ever to me that there’s no way for fashion to deliver on its targets without the help of technology.

Critically, that’s also a scary thing to admit. During this whole process, I encountered an emotion that I expect a lot of other industry veterans have felt recently: that this is all new and alien, and that perhaps their skills and experience are a bit redundant in this new digital age.

But it’s important not to let that feeling paralyse us, which is why I made the bold decision to take that manifesto and use it – with the help of some key technology partners – to create a new Fashion Technology centre in Unit 4 of Fashion-Enter, which would bring together all the waste-reducing, time-optimising, creativity-empowering technologies we could find to create a state-of-the-art microfactory that could become the home to our unique production methodology.

And that microfactory has since become a showcase for just how transformative an end-to-end digital workflow – one that heavily incorporates digital product creation – can be.

We started with the hardware, partnering with Kornit Digital at the time of the launch of their Presto Max and Atlas printers, which unlocked digital printing onto both fabric and finished garments – digital artwork and digital colour references, delivered digitally, eliminating all of the analogue iteration and uncertainty that contributed so much to waste and lost time in the past.

This wasn’t always a straightforward swap of traditional machinery for new. We had lots of locational issues, such as the machines being so big we had to obtain planning permission (utterly painful) and knock down internal walls, but we did it and that technology has been truly transformative. As well as creating a new, digital-native, endpoint, this partnership has also changed the service we can provide: instead of minimum print runs of 500 metres, we can now print in just single-metre lengths, delivering real make-to-demand and opening the door to what we refer to as “one piece flow”.

Next came Zund, which connected to Kornit, and which fully illustrates the power of single ply cutting.Our teams can now upload a range of orders, all into the system, and then have Zund cut out the individual garments into the unique sizes. Fabrications have to stay the same for each order and someone has to physically be there, attending the machine, to gather up the individual cut garments but what a dream that is! Anyone who runs a factory or sampling centre knows how expensive it is to cut out single samples – and I’ve already talked about just how damaging large-scale sampling can be for fashion’s overall workflows.

Next came Style 3D, who I know are also featured in this report, and it quickly became obvious just how important digital product creation tools would be for realising our ambition. Everyone at Fashion-Enter had high expectations for the difference it would make to shift 2D workflows to 3D, but even those expectations have been surpassed. The difference 3D has made to time, creativity, and even the creation of new opportunities has been gigantic.

As someone who worried, during this process, that technology would replace traditional skills and workflows, I’m happy to be able to report that the opposite is true – we’ve found that 3D has enhanced basically every aspect of our work, and revolutionised the way we engage with our clients. Here are just a few highlights that showcase how instrumental our work with Style3D has been to creating a lean, digital workflow without undermining any of the elements that make us unique:

- Zero waste design and ease of garment manipulation.

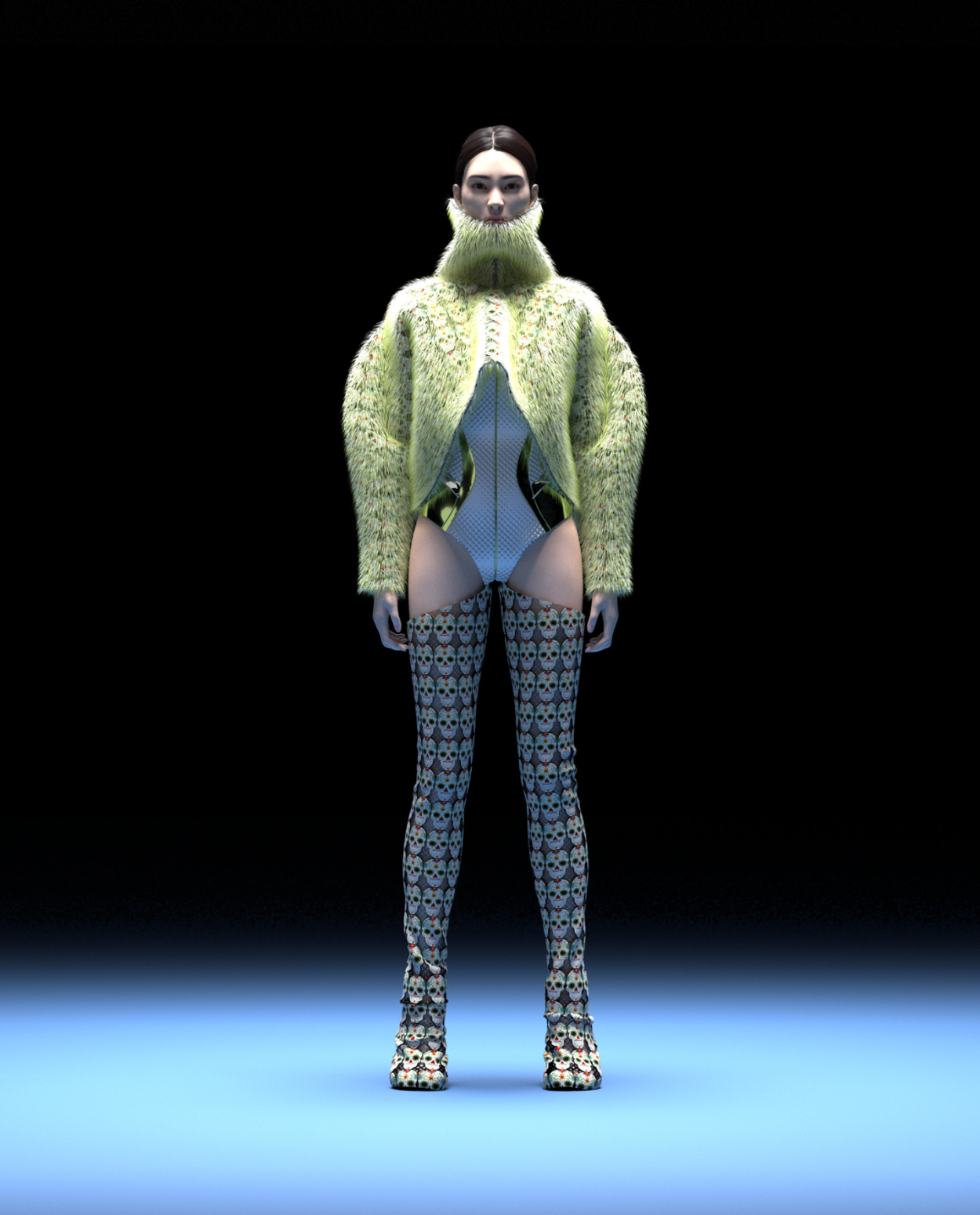

- The availability of more than 50,000 digital assets as a foundation for experimentation and creativity.

- The ability for our teams to use AI to generate new design ideas from uploaded photographs.

- The accuracy of fabric digitisation, so that virtual materials reflect not just the aesthetic characteristics but the real DNA of the fabric.

- Soft body, poseable avatars that are accurate enough for lingerie and swimwear design, where tolerances are incredibly low, and adaptable enough to tailor a base avatar for each client and even each individual customer. And these same technical avatars are also usable as virtual models, with facial expressions, believable skin tones and surfaces, hair, and eyes.

- The ease with which we can export patterns from design and visualisation and into production. Whether we’re exporting as a PDF or a DXF, the process is seamless – excuse the pun!

Then the final stage for us has been our unique collaboration with the United Repair Centre and Patagonia, as seen on screen this winter! We had Sky News review our set up, contrasting the old way of production in our Unit 14 with the new way in Unit 4. Now having repairs on site means that we can truly be sustainable and extend the life of a garment exponentially – really quantifying the impact that a DPC-enabled and all-digital production process can have on over-consumption.

So, welcome to the new age of fashion – in brief. Despite the huge advances that have been made in technology, it’s been a hard, bumpy road to get here, and one that I think as a relatively small, social enterprise has been a brave path to go down. But it’s pretty unambiguously a path we couldn’t have walked without the support of technology, and 3D / DPC tools in particular.

The one brick that hasn’t fallen into place, though, is the attitude of the UK’s big brands and retailers to proximity sourcing. So much of the negative impact of sampling and production overseas can be solved by working closely with a partner that has really proven the ability of DPC and other digital tools to deliver an in-country offer that deserves a key place in their sourcing strategies. Perhaps 2024 will be the year that the wider industry wakes up to the opportunity – and with the support of our technology partners, Fashion-Enter will be waiting.