As 3D and digital product creation (DPC) strategies have evolved, the need for a continuous supply of high-fidelity digital fabrics – assets that accurately represent real material specifications and behaviors in every respect, and can be used to fuel accurate design, development, and sourcing decision-making – has scaled with them. But as of today, that demand is still not being fully met. As brand and supplier investment in technology initiatives waxes and wanes with the economic forecast, there is some uncertainty over where 3D and DPC, and the digital materials needed to fuel it, go from here.

This collaboration between The Interline and Cotton Incorporated reiterates the solid business case for digital fabrics and explores where they should be captured, to what standard, and where – and how – can brands and suppliers obtain the most value from them. Cotton Incorporated’s CottonWorks™ platform offers the resources and expertise to support professionals in navigating these opportunities.

The Current State of Digital Materials

Cotton plays a crucial role in numerous fashion and textile products, and it is essential for brands, suppliers and manufacturers to have access to accurate and dependable cotton fabrics within the leading 3D garment design tools available today.

Despite the many reasons for fashion businesses to use digital fabrics and embrace 3D and DPC, over the past year some of the excitement around digital assets has tapered. There are many factors at play: working with 3D and DPC is a new way of operating for brands, their suppliers, and their manufacturing partners. It also needs continuous investment and commitment, and can be obstacles that occur upfront when it comes to implementation that can make it difficult to buy into.

But there is a strong business case for digital materials, the technology ecosystem surrounding them, and the processes used to optimize them. By clearly identifying the challenges that brands associate with using digital materials, all fashion industry stakeholders can begin implementing solutions to overcome them – something that will be imperative when working towards an end-to-end digital supply chain.

Why efforts are stalling and why we should keep pressing forward

When it comes to investing in and working with DPC, the initial stages can be challenging. This is particularly true from a business perspective, because it is expensive and time consuming to implement digital workflows and the return on investment (ROI) takes time to materialize. Implementing digital methods may not immediately save money or time due to the need to integrate various internal components within an organization – which often involves hiring skilled personnel, upskilling current employees, and aligning partners to new ways of working. In addition to this, scaling past easier product categories can be difficult.

However, considering the full benefits up and downstream, the ROI is still very much there and brands have proven the value of digital materials and DPC methods. Newer tools and methods for creating, managing, and sharing digital materials are now available, making it more feasible for more brands and manufacturers to create accurate, reliable materials. DPC tools are capable of handling more challenging products like outerwear, technical gear, intimates – and these are the often categories where greater value can be realized, due to the high cost of sampling these products.

Absence of top-down support and unrealistic expectations

Some DPC efforts can stall or halt altogether without the proper support from leadership. Training individuals in specialized skills, such as those needed for 3D technology and DPC, is essential for the digital transformation of any business. However, when these trained employees leave or if the company faces layoffs, their expertise goes with them – possibly leaving a knowledge gap and derailing ongoing projects. This has been a recurring issue over the past four years with the unpredictability of the U.S. employment market. Fashion companies can also set unrealistic expectations regarding digital fabrics and the broader DPC ecosystem, underestimating both the technological complexities and the time needed for successful implementation.

This challenge can be addressed through cross-functional buy-in and the establishment of realistic, long-term goals set by leadership. This approach ensures efforts remain resilient in the face of obstacles like layoffs or staff turnover. Expectations can also be managed by keeping in mind that DPC adoption is not a plug-and-play effort: it involves integrating new technologies into the design, development, and production stages. It also may require overhauling or adding to existing processes, retraining of staff, and close collaboration with external partners and suppliers.

Lack of software-agnostic solutions and interoperability

What can sometimes happen is that despite their best efforts, fashion companies can still face difficulties when it comes to adoption of digital materials and assets because of siloing of efforts and data.

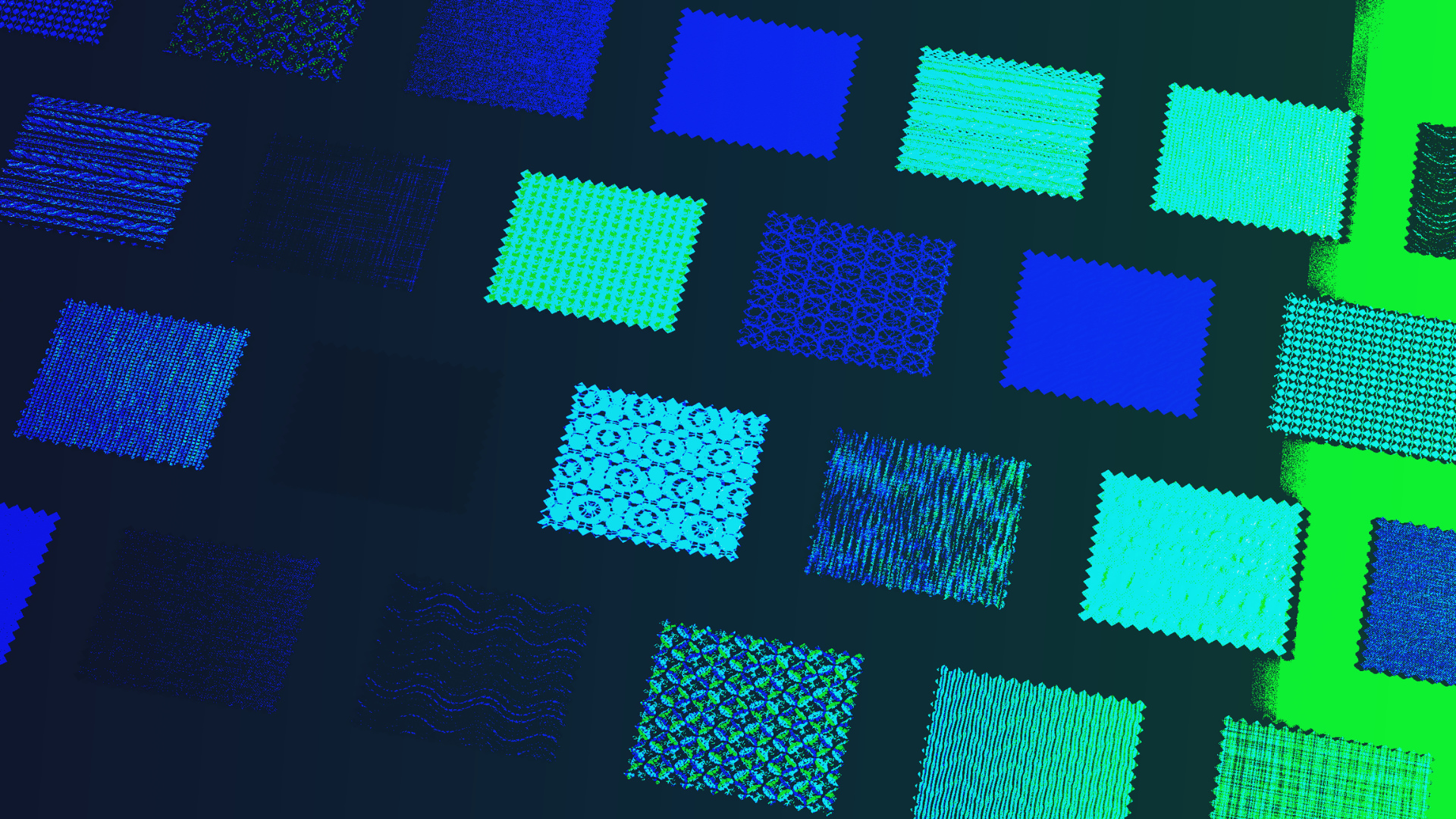

Developing or acquiring these complex digital fabric libraries can be time-consuming and costly, as it requires sourcing, scanning, and digitizing physical fabrics, sometimes across multiple seasons and collections. This integration also often needs compatibility between different software platforms to maintain it; something that is no easy task as companies may use a mix of legacy systems and newer tools, meaning a lot of coordination to ensure interoperability and maintaining quality.

The good news is that more flexible, agnostic solutions are now available or closer in reach. Siloed DPC projects can result from siloed teams within brands – however, overcoming these silos is the true transformative potential of end-to-end digital workflows.

Adjacent technologies

The fashion industry’s hesitation to fully embrace digital fabrics and belief in growing the DPC ecosystem can be partly attributed to the hype around adjacent technologies (including the metaverse and NFTs) has dwindled due to expectations exceeding actual capabilities and lack of mainstream adoption by consumers. Virtual fashion shows from the past several years have failed to impress. This has made stakeholders wary of investing heavily in new digital innovations like digital fabrics without clear, demonstrable benefits.

But it is crucial to remember that the real value is still there – separate from hype around theoretical digital spaces. The business case still makes sense, even when solely related to digital methods supporting physical product development. Here, it is important to remember the upstream and downstream benefits of accurate digital materials and digital assets that include more rapid prototyping; improved line planning that gives brands the flexibility to conduct consumer testing on products before locking in their final decisions; and shorter lead times for products that ensure closer alignment with current consumer demand. Additionally, incorporating 3D samples alongside traditional photography offers a clearer, more detailed view of products, which helps reduce return rates, and digital photography and virtual try-on provide opportunities for consumers to engage with products in an immersive way that enhances the overall shopping experience.

Standardization challenges

Another major issue is the absence of established standards for digital materials. While physical materials have long benefited from standardized measures across various properties (texture, weight, color, durability, and thermal behavior) digital materials are still catching up. This lack of standardization affects consistency, interoperability, and reliability across the DPC ecosystem. Without standards, it is difficult for brands, suppliers, and others along the value and sourcing chain to collaborate effectively, potentially leading to the very inefficiencies that digital materials aim to solve. For digital materials, the lack of industry benchmarks also makes it harder to assess the quality and authenticity of digital samples, leading to misunderstandings about what the final product will look and feel like, and resulting in customer dissatisfaction or the need for costly redesigns.

To overcome the standardization challenge, brands and suppliers can acknowledge shared accountability for developing them. At a minimum, setting clear standards between brands and suppliers is vital to ensure consistency and accuracy in digitization, regardless of who handles the process, while the industry works toward establishing broader, unified standards. Having both parties involved in the digitization process helps build trust in these digital materials.

There is also an opportunity for suppliers and manufacturers to drive technology companies to improve the interoperability of their 3D CAD tools and platforms. For all involved – brands, suppliers, and manufacturers – prior agreement on file types and formats will be essential to facilitate better communication and processes.

The renewed case for digital fabrics: sustainable, sourceable, and manufacturable

While acknowledging that obstacles to adoption do exist, the benefits of using digital fabrics are undeniable, with potential for substantial cost savings, increased design agility, and meaningful contributions to sustainability efforts.

Fabrics are foundational for all fashion brands, and for successful DPC efforts. This is where Cotton Incorporated plays a big role: it has established a position of leadership and is known for its materials being of the highest quality, that are manufacturable. Not all other libraries can say the same. The CottonWorks™ library of digital 3D fabrics boasts a variety of innovative cotton-rich materials – all available for free to download. Many of these files are compatible with CLO and Browzwear software, providing an accessible, high-quality resource for brands to seamlessly integrate into their digital design workflows.

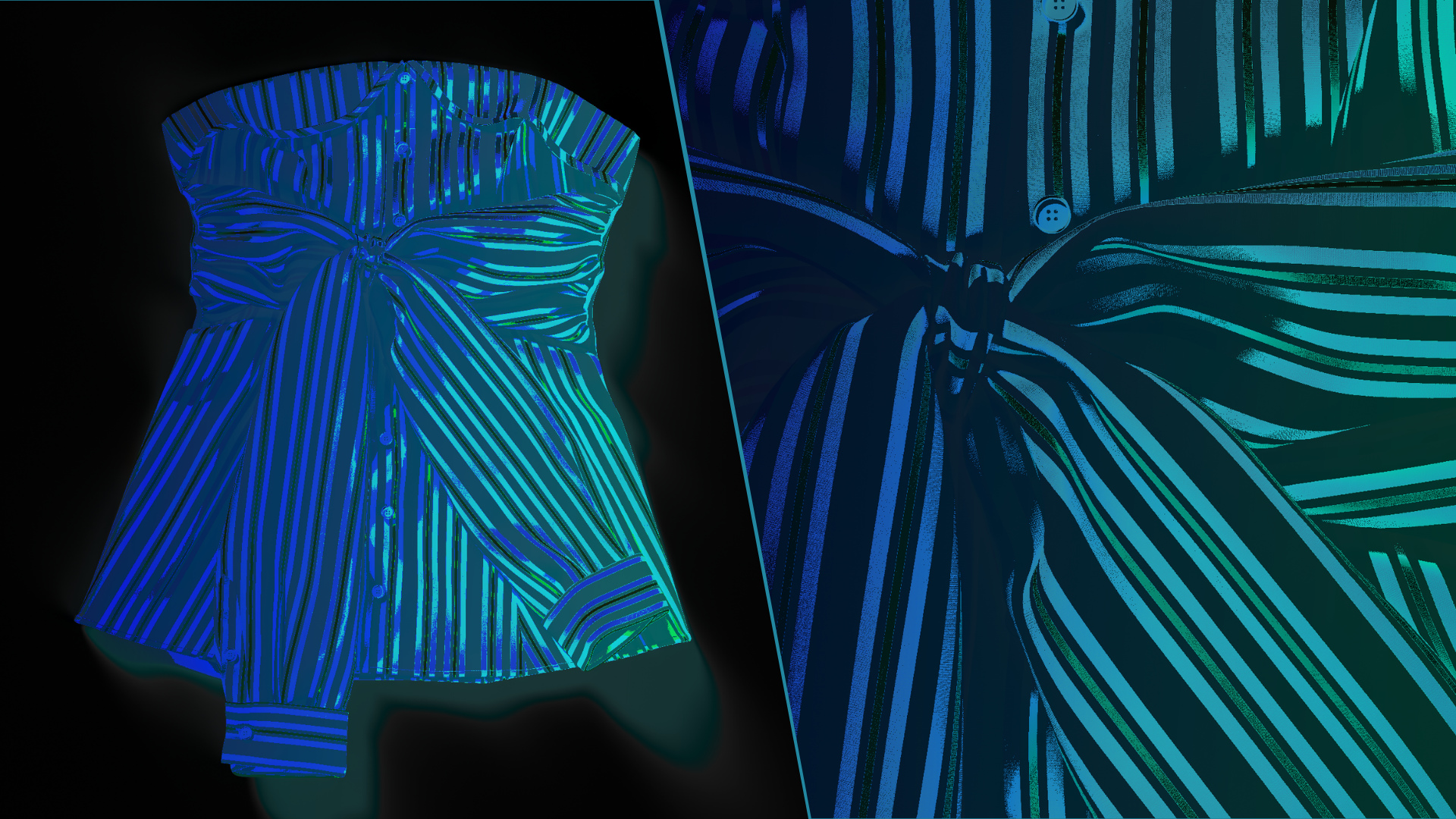

It is also critical to keep in mind the progress digital fabrics have made over time, as it lays the foundation for their future potential. Fabric digitization has come a long way. In the early stages, it was the brands that led the way, building their own digital libraries from scratch. Service providers, digital libraries, and manufacturers didn’t become involved until several years later. The first phase of DPC saw brands handling everything on their own. In phase two, service providers and early digital libraries stepped in, taking on the labor-intensive work of testing and scanning materials. Now, phase three is unfolding, marked by more scalable and cost-effective solutions, with AI increasingly replacing the need for physical testing and automating the scanning process.

Today, brands are increasingly deriving value from digital materials both upstream and downstream in their supply chains. Upstream, integrating digital fabrics into DPC workflows, designers can quickly explore and visualize new designs, cutting down the time needed for prototyping compared to conventional physical sampling methods. Accurate physics measurements also allow tech designers and patternmakers to begin 3D garment fitting long before a physical prototype is created. This also has the benefit of minimizing physical sampling, leading to reduced waste, shorter production times, and lower resource consumption related to manufacturing, shipping, and storing garment samples. This is especially important in today’s fashion landscape, where tightening sustainability regulations are being implemented worldwide.

More benefits of accurate digital materials and digital assets also include better line planning, the ability to do consumer product testing before making final decisions on line plans, and achieving shorter lead times to ensure products better match what consumers want to buy, leading to improved sell-though. This decreases return rates for products using 3D samples in addition to photography. There are also possibilities of doing digital photography for sales pitches and marketing efforts, and virtual try-on for improved customer experience.

Practical steps: building out the end-to-end digital supply chain

Building end-to-end digital supply chains is essential for unlocking the full potential of DPC, and while challenging, it is within reach for many brands and manufacturers when considering the following practical steps.

Business-centric strategies

Brands can begin with small-scale DPC projects that allow them to test the waters, focusing on specific product lines or particular processes; learning and adapting without overwhelming their existing operations. Successful projects can provide tangible examples of benefits, helping to build internal support and demonstrate the value of digital fabrics. A longer-term roadmap could include specific goals, timelines, and metrics to measure success, as breaking down the transition into manageable phases makes it easier to track progress and make necessary adjustments along the way. Especially for those looking at ROI, regularly communicating the long-term benefits of DPC to all stakeholders – including employees, partners, and suppliers – can help to manage expectations and maintain momentum. Showcasing early wins and incremental improvements can also help to keep teams motivated and focused on the larger vision.

Scaling DPC efforts effectively

To address the problem of DPC efforts stalling or failing to scale, brands need to ensure that they are using updated tools, and to lean on suppliers who are increasingly capable and knowledgeable. To mitigate the risks associated with skilled employees leaving the company and their knowledge with them, companies need to implement solid knowledge-sharing systems and create an environment where learning is continuous and integrated into the company culture. This will involve a top-down approach to employee training and ensuring that digital methods are broadly integrated rather than remaining siloed. Embedding digital strategies into the core business operations and ensuring that leadership is visibly committed to these initiatives can help maintain the momentum needed for successful digital implementation.

Optimal methods and locations for capturing fabric data

Here, sharing responsibility for digitization among brands and suppliers – with both parties agreeing on and understanding the process and owning parts of the creation – will support the development of a rich digital materials library. For example, brands could handle seasonal and sourced fabrics, while manufacturers could focus on providing core materials in digital format. In addition, AI is already playing a role in reducing the manual work of manual physics data testing for fabrics, and of generating the supporting texture maps required for high-fidelity digital materials. With ongoing advancements in AI models, there is expanding potential for growth in this area.

Digital materials are essential in any digital workflow due to their practical, sustainable, and collaborative benefits. The digital ecosystem will reach its full potential when materials and factory production processes are fully digitized, complementing the significant advancements in 3D design and fit. Brands should view their investment in digital fabrics and the broader 3D and DPC ecosystem as a long-term commitment that has tangible benefits both upstream and downstream.

Cotton Incorporated excels as an industry leader by aligning with market needs and providing extensive support through comprehensive resources. By offering downloadable 3D digital cotton fabrics, they significantly simplify the process of searching for and creatively exploring product ideas. The task of overcoming the obstacles associated with digital materials mentioned here are possible to overcome with the right mindset and approach to their integration, and keeping in mind the ultimate goals for sustainability and better workflow for all stakeholders.

About our collaborator: Cotton Incorporated is a not-for-profit organization aiming to benefit every link on the cotton supply chain while increasing the demand for and profitability of cotton through research and promotion. The company’s efforts are focused across every area of the cotton life cycle, from fiber through finished product. Cotton Incorporated’s CottonWorks™ is your go-to textile tool for discovering what’s possible with cotton. From fiber and manufacturing education, sustainability insight, fabric inspiration and trend forecasting, CottonWorks.com has the information you need to stay in motion. Questions? Contact cottonworks@cottoninc.com.