Leading flat knitting solutions provider SHIMA SEIKI MFG., LTD. of Wakayama, Japan, together with its Hong Kong and Chinese market subsidiary SHIMA SEIKI (HONG KONG) LTD., will exhibit at the ShanghaiTex 2025 exhibition held in Shanghai, China this month. This marks the return of SHIMA SEIKI to ShanghaiTex after a 14-year hiatus, its last exhibit at the show having been in 2011. The exhibit will emphasize the company’s continuing global leadership in computerized flat knitting by presenting its unique capability to provide solutions to a wide range of customers with diverse needs through uncompromising Made-In-Japan quality and technology. To this end, Shima Seiki will have on display an all-new line-up of shaped knitting machines, ranging from flagship machine technology to entry-level shaping. Details follow.

SES®-R NEW

SHIMA SEIKI’s legendary SES® series was the world’s first short-bed full-fashioning machine that could produce shaped pieces for one garment at a time and supported multi-variety, small-lot, quick-response production. First introduced in the 1980’s to a market filled with long-bed machines knitting square fabrics for cut-and-sewn products, it was a machine that challenged the status quo. Now the current status quo established by the SES® series is once again being challenged with the new SES®-R. SHIMA SEIKI’s next-generation shaping machine has been “Reborn” with an all-new spring-type moveable sinker system that features switchable sinker stroke and pause function for increased capability in knitting dimensional sinker patterns. Auto yarn carriers and loop presser beds mounted above both front and back needle beds enhance performance in both inverse plating and inlay knitting. Shown at ITMA Milan in 2023 as a prototype, the production version of the flagship SES® -R is shown at ShanghaiTex in 14 gauge, with a 52-inch (132 cm) knitting width to support knitted items in larger sizes.

SES®-R Standard NEW

SHIMA SEIKI’s SES®-R flagship shaping machine also comes in a more basic version called Standard. As with the SES®-R, SES®-R Standard features an all-new spring-type moveable sinker system for increased capability in knitting dimensional sinker patterns. Capable of high value-added knitting of quality knitwear, SES®-R Standard can be fitted with optional features for increased capability to support continuously changing demand in a fluctuating market. SES®-R Standard makes its debut at ShanghaiTex in 14 gauge, with a 52-inch (132 cm) knitting width to support knitted items in larger sizes.

N.SSR®132 NEW

SHIMA SEIKI’s global standard in shaped knitting, the N.SSR® series, now includes an even more cost-effective choice. The new N.SSR®132 maintains high productivity with a compact, lightweight carriage and maximum knitting speed of 1.2 meters per second, as well as quick carriage returns with the R2CARRIAGE® system. N.SSR®132 carries over proven SHIMA SEIKI technology such as our renowned Digital Stitch Control System (DSCS®), spring-type moveable sinker system, stitch presser, yarn gripper and cutter, and takedown comb. New features include a 52-inch (132 cm) knitting width for supporting larger sizes and optional sub-rollers, offering the flexibility required for responding to various customer and market needs. Realizing excellent cost performance while ensuring Made-in-Japan quality, safety, reliability and user-friendliness, N.SSR®132 sets a new standard for a new era in computerized flat knitting machines.

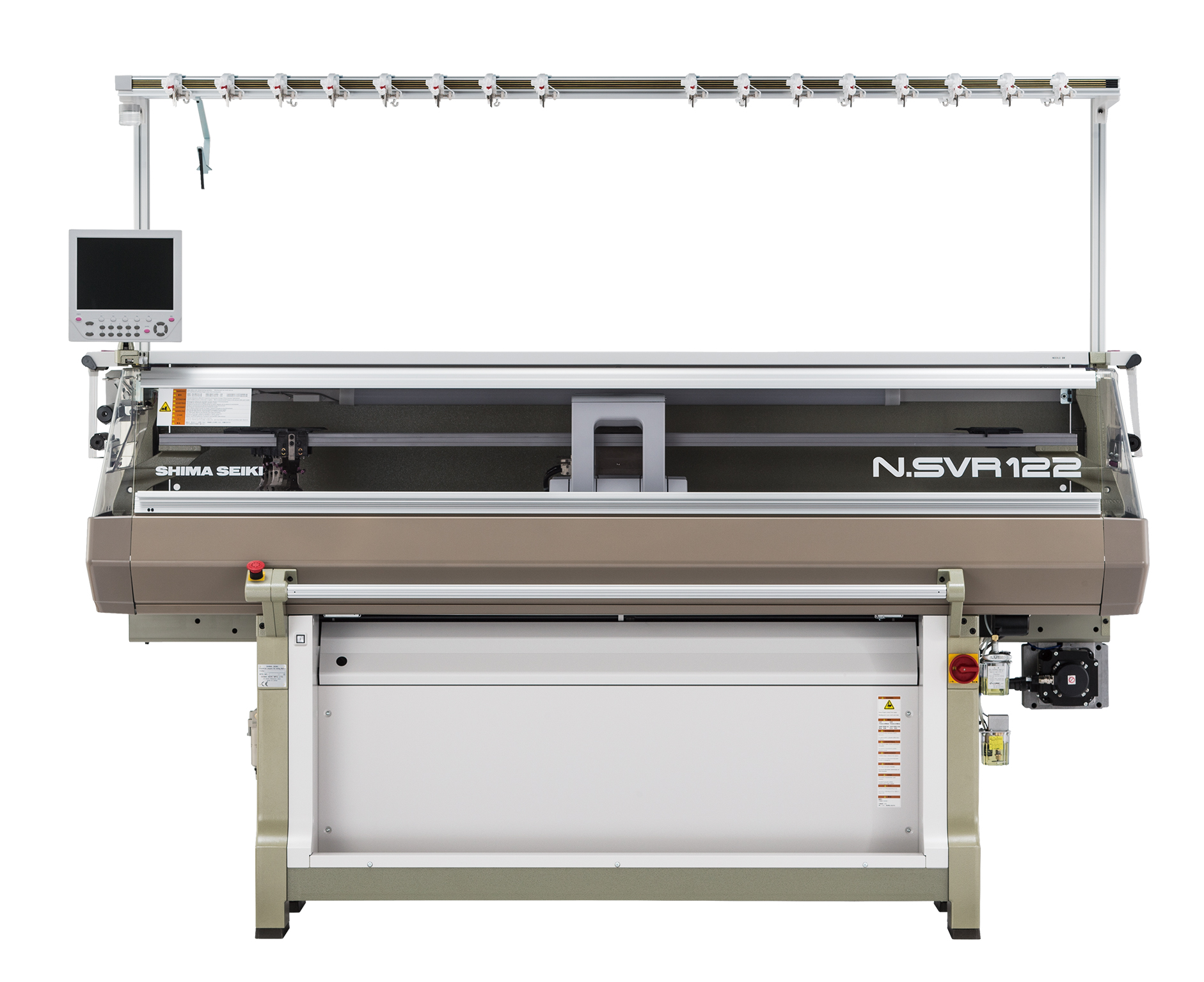

N.SVR®122 Prototype

The N.SVR®122 computerized flat knitting machine is considered the benchmark in computerized shaping technology and offers the latest features which in themselves have become industry standards. These include spring-type moveable sinkers, takedown rollers, Rapid Response R2CARRIAGE®, DSCS® Digital Stitch Control System, stitch presser and takedown comb. Made-in-Japan quality, reliability, productivity, user-friendliness and cost-performance combine to satisfy the high expectations of the world’s fashion industry. N.SVR®122 is shown in 22-gauge version at ShanghaiTex as a prototype to demonstrate efficient production of high-quality ultrafine gauge fabrics.

Exhibition Details

Name: ShanghaiTex 2025

Date: Tuesday, 16th – Friday, 19th December 2025

Hours: 9:00AM – 6:00PM (Final day: – 3:00PM)

Location: Shanghai New International Expo Centre, No.2345 Longyang Road, Pudong New Area, Shanghai 201204 China

Organizer: Booth No.: Shanghai Textile & Information Exhibition Co., Ltd.

Hall N3, Booth A20

Exhibited Technology

SES®-R V14G | Computerized flat knitting machine |

SES®-R Standard V14G | Computerized flat knitting machine |

N.SSR®132 V7G | Computerized flat knitting machine |

N.SVR®122 C22G | Computerized flat knitting machine |

SHIMA SEIKI Profile:

SHIMA SEIKI MFG., LTD. of Wakayama, Japan is a leading manufacturer in the computerized flatbed knitting machine industry. With complete systems integration from planning, production to sales promotion and retail sales, SHIMA SEIKI has been dedicating its products and services to the knitting industry worldwide through the latest in computerized knitting technology.

SHIMA SEIKI is also the pioneer in complete garment manufacturing technology—called WHOLEGARMENT® —wherein an entire knitted garment is produced on the knitting machine without the need for linking or sewing afterward. Since its commercial introduction in 1995, SHIMA SEIKI has been the undisputed leader in WHOLEGARMENT® knitting technology with 30 years of field experience and know-how, not to mention over 2,900 related patents and patents pending worldwide.

Meanwhile SHIMA SEIKI’s SDS®-ONE APEX series 3D design system and APEXFiz® design software feature ultra-realistic knit simulation for creating virtual samples. Virtual samples minimize time, cost and material associated with the sample-making phase. Virtual samples can also be used to gauge consumer response to items before going to market, effectively realizing production based on demand forecasting. Inventory can therefore be optimized to minimize leftover stock, realizing smart, speedy and sustainable production.