Released in The Interline’s DPC Report 2023, this executive interview is one of a sixteen-part series that sees The Interline quiz executives from major DPC companies on the evolution of 3D and digital product creation tools and workflows, and ask their opinions on what the future holds for the the extended possibilities of digital assets.

For more on digital product creation in fashion, download the full DPC Report 2023 completely free of charge and ungated.

Key Takeaways:

- As 3D and digital product creation workflows mature, the areas they can deliver value are becoming more diverse – opening up the opportunity for technology partners to cover common ground as well as further developing their specialisations.

- The growth of the design-focused technology ecosystem has placed considerable power in the hands of creatives, but this empowerment is also placing a burden on technical and development teams. The drive is now to bridge art and science, and to ensure that creative design can be supported through precision in fit, patternmaking, and production.

- With growing recognition that 3D and DPC pipelines will not be built from a single, all-encompassing solution, fashion’s challenge is now to build ecosystems from different, deeper tools which can work together to carry through a digital twin that remains reliable, trustworthy, and producible.

What do you believe are the greatest opportunities that are realistically achievable, in 2024, through investment in DPC talent and tools?

The reach of digital product creation is so broad that I believe you can pick almost any key performance indicator (KPI) or strategic objective and deploy 3D and DPC tools to stand a good chance of improving on it. If I were to pick the top KPIs, I’d say speed and waste are two of the most important metrics for every brand at the moment, which means further elimination of physical samples from the process and the further acceleration of the end-to-end workflow.

But I think that the beauty of where we are today is that the industry is maturing, and with that maturity comes a more complex and sophisticated suite of KPIs to choose from: how you elect to use DPC, and how and where you measure the value you get from it. For a lot of companies, those areas will overlap, because the industry has a set of common challenges, but in some areas, they will contrast and you’d have to wisely manage those tradeoffs by prioritising based on your specific focus.

Everyone is trying to create better fashion and better fit and, at the same time, trying to address vital sustainability concerns and comply with legislation. Success here will look like customers having more confidence that what they see on the screen will fit them well with consistency, and this (combined with better product quality) will translate into motivation to wear that item more often, and to keep it for longer.

Then, there’s the issue of cost and margin. What is the cost to manufacture the product, to deliver it, and eventually, for the consumer, to buy it? How do we, as an industry, optimise all those different elements to help brands deliver better products, keenly priced, that have a reduced impact on the planet? I think 3D and DPC tools have a lot of the answers to these key questions, as well as to the more specific ones that individual brands are asking.

We’ve seen a lot of brands and retailers really accelerate their DPC strategies, focusing heavily on the design end of the spectrum. As a result, there’s the possibility that the industry’s approach to scale is becoming lopsided, with high adoption in design translating into bottlenecks in development and production. What are your feelings on how fashion can overcome that bottleneck? Will it come from conforming different types of workflows to one tool and one technology, or diversifying and growing the solutions and the capabilities that are available to different users?

At Optitex, we are keeping an eye on what drives effective workflows from design to the final stages of production. That’s also a vision that the wider industry shares, and I believe that if we take a step back and look at the history of DPC strategies, we can chart that evolution across the whole of fashion.

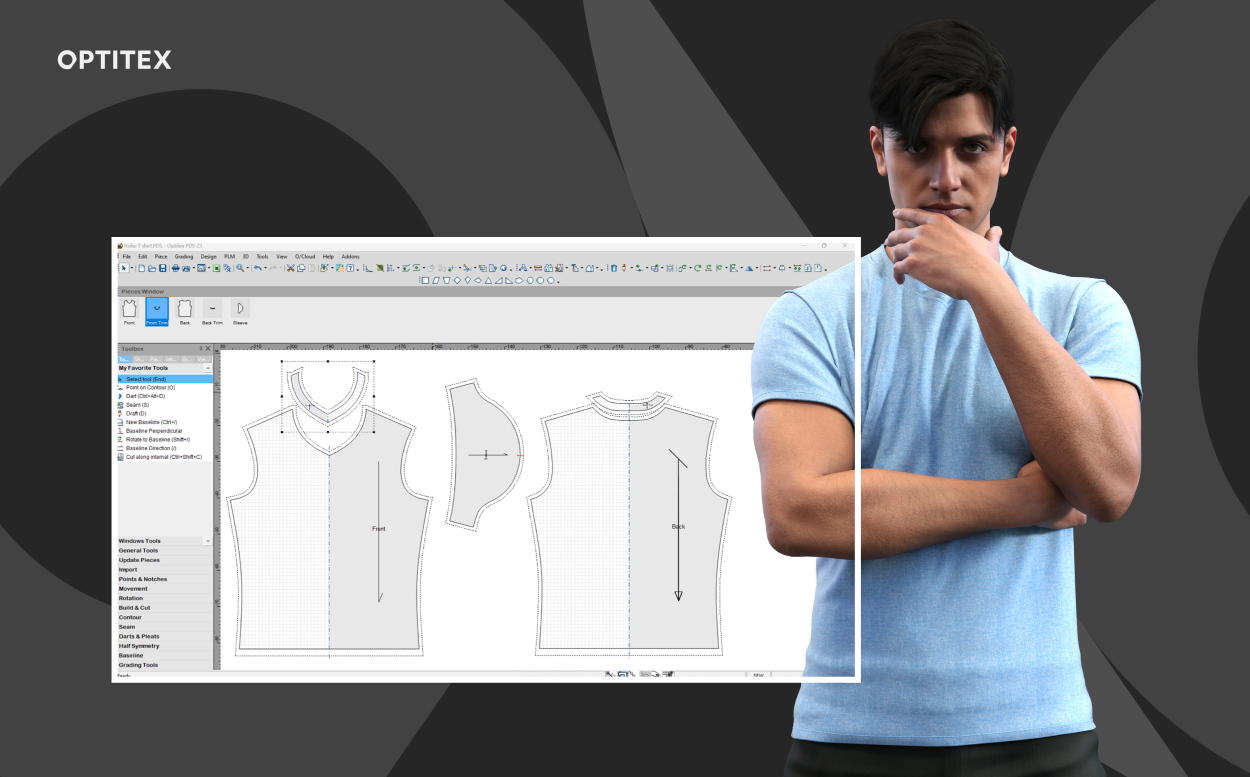

The initial stage was addressed by putting digital tools into pattern making – that was maybe 10 to 15 years ago – and then the focus moved to leveradge 3D to reduce physical samples and some other areas along the chain, connecting different users both up and downstream.

In the past five years, the focus has definitely shifted to the design phase, where designers had been left behind sketching on Adobe Illustrator, or in some cases, even just using paper and pencil, and this was detached from body measurements and from fabric properties. This hybrid 2D workflow made it very difficult to communicate design intent further down the workflow chain, and that’s where a lot of the gaps and the miscommunications that characterised the average product lifecycle arose.

Now, those gaps have significantly narrowed, thanks to different tools for designers that enable them to design in 3D, using digital materials that reflect the look and drape of fabrics. This design-focused ecosystem has made it much easier for designers to really express themselves in 3D, to shorten the distance between an idea and reality, and to help ensure that their work relates to the body measurements, proportions, fabric, colorways, and so on. This has helped to eliminate, or at least greatly reduce, that original bottleneck.

The challenge now comes at the intersection of design and collection reviews and product development, or the junction of art and science, where you have alleviated to a degree the design phase bottlenecks, and are now generating more production-ready candidates to be developed. Let’s also consider that you have more creative designers and less pattermakers out of fashion education institutes globally. And this is essentially the new bottleneck: where you have a huge amount of new power in the design community’s hands, which is creating a significant burden on the technical side of development, perfecting fit, pattern making, and production preperations.

This is also why, when it comes to the production stage, there are a lot of designs that need a vast amount of work in order to be converted into producible patterns, and to move forward in a reasonable way. Even though the technical foundation is there, I don’t believe that, as an industry, we’re effectively connecting design to development, or development to production.

We are seeing different approaches to deploying DPC. For example, in the past in the US, many organisations have shifted the work of creating digital assets to their trusted partners in the Far East, or Africa, or India – the same way that they have devolved responsibility for pattern making to the places where expertise and knowledge are more concentrated. That way, the brand stayed focused on communicating with consumers on social media dealing, raising brand awareness, and then feeding the different sales channels – but abstracting the rest. We now see that starting to change and we witness a pull-in of some of this product development ownership, or at least tighter control, back at the brand’s side.

In other places, like in Europe, and especially in the luxury sector, it’s different. Consider somewhere like Italy – that stands out as having a lot of respect for accuracy and that hand-crafted, detailed touch and quality – you see many businesses that are vertically integrated. The designers and the pattern makers, and even the producers, are sitting very close by or even in the same company, and that expertise is more evenly distributed and more accessible.

But even with these differences in geographies, we still see a common trend that technical designers and pattern makers – a small and shrinking pool of talent – are having to deal with an influx of new design ideas, and up until recently, there was a lack of tools that were really oriented at addressing their specific needs. So you have fewer people needing to do more work, and that’s a problem the industry – and technology vendors like Optitex – need to think hard about how to address.

But whatever the workflow, and irrespective of supply chain structure – from distributed to full vertical integration – we see a growing need for greater control, visibility, and management of product development, across every product category and every business size. And that’s where technology providers like Optitex come in: our tools are designed to release those new workflow bottlenecks, and to provide confidence and reassurance that the volume of development tasks can be handled efficiently and effectively.

Thinking about all that further, it feels as though there’s a transition happening where fashion needs to migrate away from the idea that DPC is a single strategic objective, to it being a transformation made up of different disciplines, different workloads, and separate-but-related jobs to be accomplished. Whether they’re design tasks – bringing ideas to life – to development tasks that hinge on pattern accuracy and fit, each of them needs a different approach and potentially a different solution. How do you think about developing tools that have the right domain expertise and the right focused capabilities and proficiencies to deliver on those specific needs?

The first challenge, as I see it, is how to move digital assets from one tool to another without losing a lot in translation. As you mentioned, there are separate jobs to be done, but the relationship between those jobs must be maintained.

This, I believe, is going to be solved organically in two ways: greater industry maturity and uptake of different solutions will drive interoperability through demand, and as a result, technology companies will realise that no single solution is going to dominate the entire market. The days of envisioning a DPC sector that’s entirely dominated by one company are over, and I believe essentially every brand that creates or uses 3D assets has a pipeline and an ecosystem built up of multiple different solutions.

In Optitex’s case, though, we’re confident that no one is going to outpace us in certain areas, and so we feel secure in our specialisms – and that’s being borne out by the way our customer base is continuing to increase. There is room for everyone in the market, provided you have something to offer and something that you can add to that overall ecosystem. As a software and solutions company catering to a mature market, you can afford to really focus on certain areas where you have a competitive advantage and have more value to deliver.

With that comes more confidence and openness and a willingness to shake hands with other players in the ecosystem and make sure that those assets I talked about can travel freely from one end to another. The solution that provides the inputs for your users, or that takes the outputs of your platforms and allows others to build on them, is not your competition.

The second challenge is to better understand the job to be accomplished, and what each person or workflow element needs. The market has a good idea of the capabilities it wants to create, and the expectation is that technology companies like Optitex will work to build products that meet those needs.

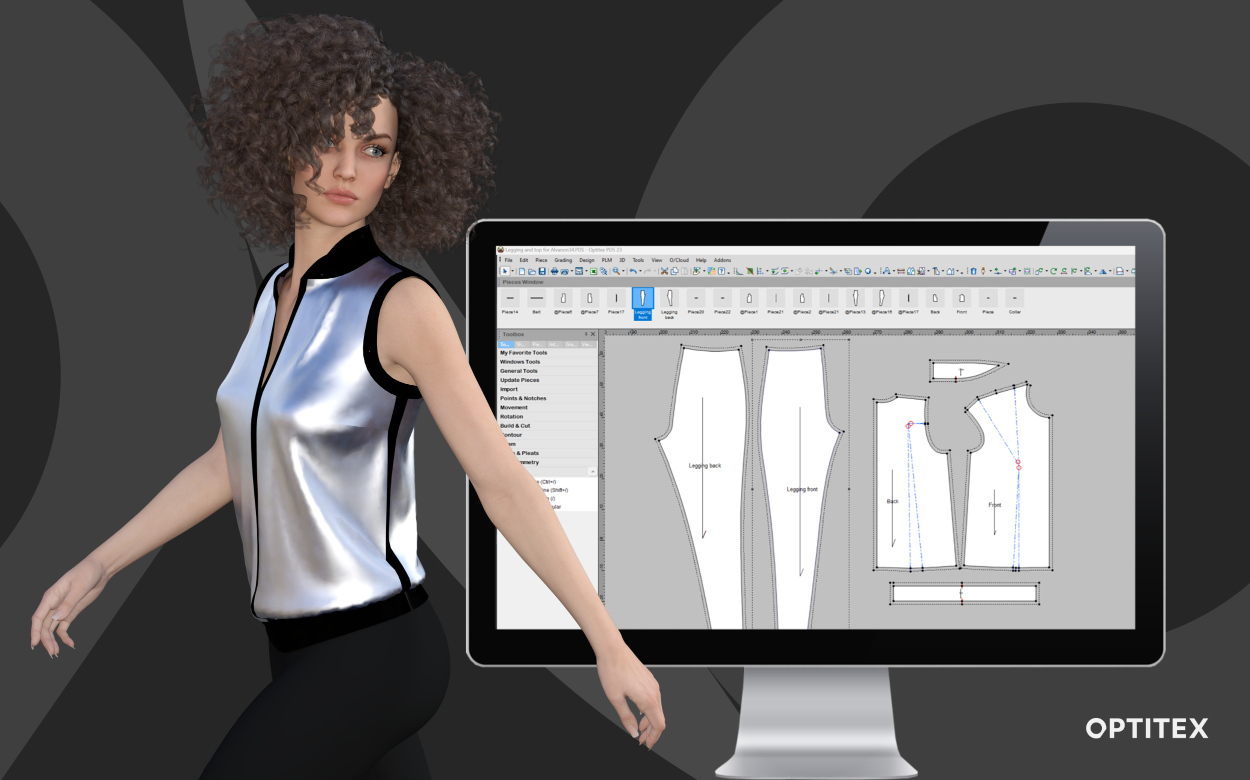

For example: we make product development a high priority in our solutions, as most of our customers deeply value having accurate fit – whether that’s for customer loyalty reasons, as a tool to help reduce the incidence of returns, or because they are building more diverse collections and moving towards more complex product mixes and short-run production. And some of our customers are even more sensitive to fit in particular areas, because it’s the nature of their business. For example, when creating professional uniforms, a collection is designed only once or twice a year, but every person across a broad spectrum needs to be fitted properly. These are not areas where companies are keen to accept compromises in functionality or features, so they are areas we’ve chosen to specialise in.

In terms of pre-production, too, we have also built even more comprehensive nesting capabilities, and made sure that fabric utilisation and waste reduction are things that our users can easily tap into.

Across the full scope of functionality, our new developments are roughly split into 70% improvements and innovations to core platform capabilities, and 30% oriented towards specific, specialised tasks.

We can anchor a lot of this discussion in a very old question: end-to-end or best of breed? That’s been at the heart of most big enterprise technology initiatives for the past few decades, and it’s a testament to the maturity of the DPC ecosystem that it’s now become the operative question for 3D and digital product creation as well. What do you believe the answer is here? And how have you approached positioning Optitex as a boutique software house with a clear desire to specialise?

At Optitex, we have been on quite a journey with this concept. At the beginning, when we – along with the rest of the technology vendors – were trying to educate and motivate people to adopt DPC, we focused on the end-to-end side because standards weren’t mature enough to assure compatibility.

Back then, those partnerships and that interoperability that I spoke about earlier were anything but guaranteed. And we also saw that our customers, at that time, were not willing to invest in multiple tools; they wanted something easy-to-deploy that could address their most burning issues, and they’d try to scale up from there once those critical challenges were solved.

For most of the industry, we are still in that scaling phase. And I think almost everyone reading this publication would agree that meeting the industry’s wider expectations has not been a matter of building broader solutions that try to swallow up as much process coverage as possible, but deeper tools that deliver what customers really need and recognise when the rest is better left to other, equally deep products that cater to other areas.

At Optitex, we understand product development inside and out. We have people who can converge the knowledge around design and production to ensure that when making a digital twin, it is reliable and trustworthy and producible, and that it will fit human models as well as it fits avatars. We believe we’re unmatched in this domain: linking 3D to pattern accuracy and producibility.

A lot of fashion DPC strategies are currently being driven by downstream use cases such as virtual photography. Behind those final pixels, pattern accuracy, fit simulation, and producibility still count for a lot, and Optitex have been flying that high-precision flag for a very long time. Do you believe it’s as relevant as it’s ever been for product development teams and manufacturers to be able to pick up 3D files that began life in design and run with them for virtual fitting and production? Because that seems like the distinction between a digital asset and a digital twin.

I think that it’s more relevant than ever, and this relevance will increase in the near future. I see this all as a pendulum that swings between different priorities depending on the most pressing challenge the industry at large is facing. At a given time, that challenge might be production automation, or cost sensitivity, or the explosion of eCommerce.

Right now, in a climate that’s being shaped by a very delicate balance of price, quality, and sustainability, I think trust is the biggest challenge the industry is facing. Whether it’s fit, quality, durability, sustainable materials, ethical labour, inclusivity, or a range of other metrics, consumers are looking for brands they can trust, and the value for those brands lies in greater loyalty, reduced returns, and much more.

Critically, those are all elements that I see as being “product development” tasks. Design, manufacturing, and marketing obviously influence those outcomes, but they’re principally determined by the decisions taken in product development, and by the tools that those specialised teams have to support them.

Many technology tools have addressed and alleviated problems around design, and now that bottleneck is moving into product development. So I think the spotlight is now on where we have chosen to specialise, as a company, and it will stay here for the next few years at least.

How would you describe the ideal 3D / DPC pipeline – category-specific or generalised – and what barriers are currently preventing it from being built and widely adopted? What pieces still need to be put in place for fashion to stand the best chance of achieving what you define as the full-scale vision for DPC?

The most important consideration is to choose the right tool for the task, rather than trying to identify and implement an end-to-end solution – and focus on the job to be done rather than the technology behind the scenes that enables it.

From there, the next obstacle for the wider industry to overcome is making sure that users are not forced to become IT experts in terms of managing digital assets and sharing them with other stakeholders in the industry. It should not be inherently more difficult to communicate and collaborate based on a 3D asset than a 2D one, but that’s not currently the case.

For this to happen, we will need to see better, more respected standards that allow for easier, more streamlined integration. For instance, making it possible for two different companies to support a certain file type and transfer even the smallest details – stitches, cut data and buttons and all the rest – so that the items stay accurate and producible as they move between different environments. Today, that breaks down easily, and people end up doing a lot of work that is not their core focus, so valuable time and effort is wasted.

The other thing that needs to happen more than ever before is more cooperation within the fashion technology ecosystem, even between competing entities. This will come as DPC evolves further, and the stakeholders gain the confidence that the playing field is big enough for everyone, but it’s something that also needs to happen outside this particular technology segment.

Now is the moment to be more cooperative than competitive. The idea is to focus on the customer and deliver more value to them, ensuring they, in turn, can focus on their work and not on struggling with the technology when dealing with taking assets and sharing them with other entities and stakeholders.

As we talked about earlier, there is also an ongoing bottleneck in development that is being exacerbated by a high demand for technical proficiency and core skills that are in very short supply in most markets. Technology has the potential to bridge this gap, and to help democratise pattern development and other technical practices, so there’s a very real barrier to scale there that can be at least partially solved by implementing the right solutions.

Taken together, these technology-enabled changes are how we get to the next level of maturity, they’re how we get progressively further towards the ideal vision for DPC, and they’re a way for the DPC community and the capabilities of its broader toolset to continue to expand.