Released in The Interline’s DPC Report 2024, this executive interview is one of a nine-part series that sees The Interline quiz executives from major DPC companies on the evolution of 3D and digital product creation tools and workflows, and ask their opinions on what the future holds for the the extended possibilities of digital assets.

For more on digital product creation in fashion, download the full DPC Report 2024 completely free of charge and ungated.

Key Takeaways:

- CLO advocates for a step-by-step approach to DPC implementation, with companies starting in design and development before expanding to other processes – making the investment more manageable and practical.

- Rather than complete system replacement, successful DPC adoption often involves using 3D platforms alongside existing systems, allowing for gradual integration and expansion.

- The business case for DPC is supported by five key benefits: improved efficiency and speed to market, enhanced sustainability through reduced physical sampling, significant cost reductions, personalized customer experiences, and new revenue opportunities in digital spaces.

In a difficult climate for fashion (and retail in general) new and ongoing investments in tech and talent-intensive initiatives like digital product creation can be harder to justify. Do you believe the business case for 3D / DPC is strong enough? And how is that business case evolving to meet a changing industry?

As many of your readers know, there’s never really been an easy or best time to undertake big investments; the real question is, can you really not afford to do it, when the upside of these initiatives are so great when implemented properly? The road can seem long and daunting, but when we look at some of our most successful clients, many have effectively implemented 3D/DPC by adopting a step-by-step approach. For instance, they start by using 3D software in the design and development stages and then gradually expand their application to other processes.

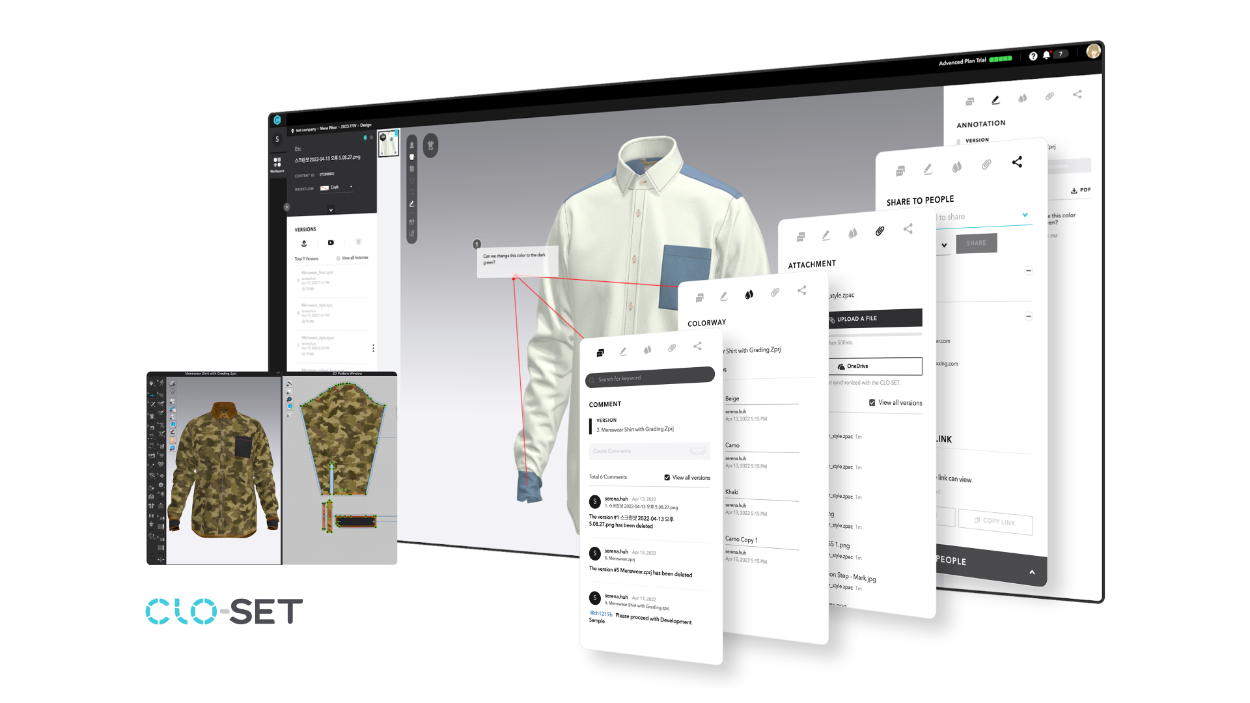

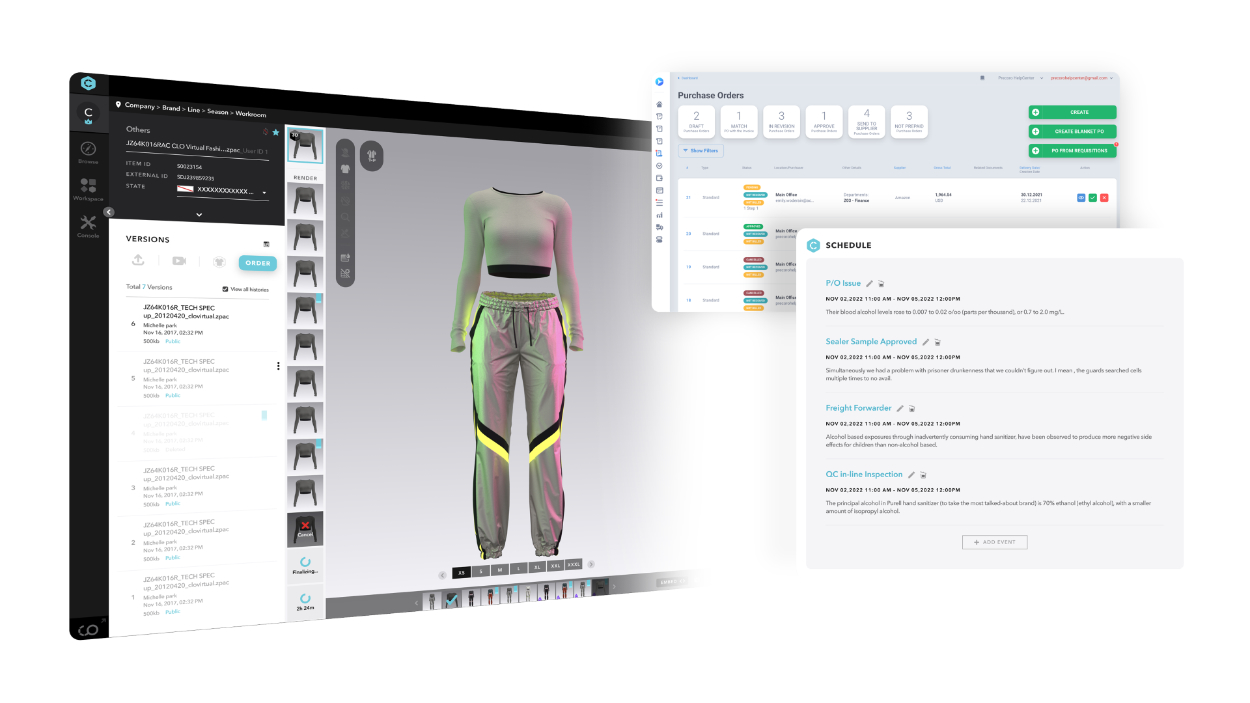

From a platform perspective, what we see is that companies are not entirely replacing their existing Asset Management Systems or PLMs with 3D-based platforms. Instead, they use 3D-based platforms alongside their existing systems, progressively expanding the scope of 3D within their workflow. Our communication platform, CLO-SET, is one way for companies to embark on their DPC journey, as it integrates seamlessly not only with CLO software but also with various PLM and Asset Management systems that they already work with.

Through this incremental adoption approach, many of our clients have benefited in these key ways:

1. Efficiency and Speed:

3D technology reduces repetitive tasks in the design and sampling stages, significantly shortening time-to-market. This allows companies to respond more quickly to dynamic market demands.

2. Sustainability:

Virtual sampling and digital prototyping greatly reduce physical sample production, minimizing environmental impact. This aligns with the growing emphasis on sustainability among both brands and consumers.

3. Cost Reduction:

By decreasing the need for physical sample production and shortening development cycles, companies can achieve substantial operational cost savings.

4. Personalized Customer Experiences:

New areas like digital fashion enable highly customized experiences, opening up fresh business opportunities, particularly for the digitally native generation.

5. New Revenue Models:

Virtual clothing sales in the metaverse, digital exhibitions, and virtual fittings are just a few examples of how 3D/DPC can drive new streams of revenue.

In conclusion, 3D/DPC offers a practical and scalable approach for companies to begin their digital transformation journey and gradually expand its scope. It addresses current industry challenges and serves as a powerful business case to support sustainable growth in an ever-changing market.

While DPC adoption is generally increasing, this is by no means a universal trend; the speed, shape, and scope of the digitalisation of design, development, sourcing, and storytelling varies a lot depending on brands, product categories, and a host of other variables. Is there such a thing as a single strategic direction that can be applied to any brand to help them capitalise on the core benefits of 3D? Or does every initiative need to be unique? And where do practical applications of AI come into the picture?

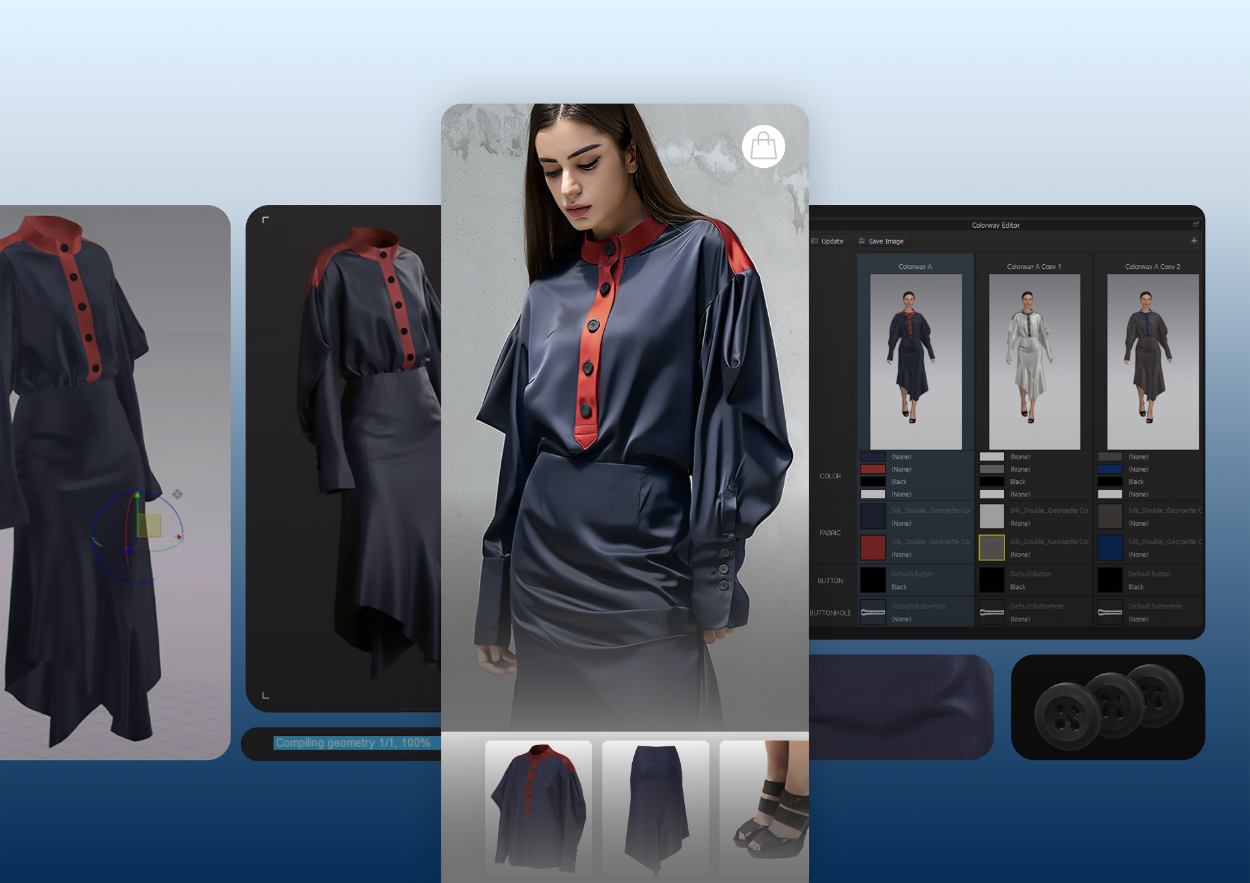

Each company’s 3D/DPC adoption journey will inevitably vary. We at CLO are proponents of developing a tailored solution for each of our clients that reflects their unique circumstances and goals. For example, brands already working with vendors proficient in 3D workflows may focus on leveraging 3D technology in processes like planning, production, and retail rather than prioritizing asset digitalization. On the other hand, companies without such capabilities must first address the foundational task of asset digitalization before moving toward workflow digitalization.

Delving deeper, each fashion company has its own priorities and areas where they aim to adopt or enhance 3D usage. For some, this might mean focusing on the design and development phase, while others may wish to integrate 3D into supply chain management or customer engagement.

Our approach is to provide consulting services tailored to each customer’s environment and objectives – the way CLO offices are located and are staffed reflects this. By working closely with clients, we help identify the most effective methods for implementing DPC, ensuring that their digital transformation journey aligns with their specific needs and delivers measurable value. This flexibility and focus on customization are key to ensuring the success of 3D/DPC strategies across diverse companies and use cases.

How do you see the balance between DPC as a technology project and DPC as a whole-industry cultural transformation? We talk a lot about change management as a key dimension of fashion technology, but there’s a difference between implementing an individual solution and rolling out a fundamentally different, value-chain-wide approach to creating and communicating products. What’s your approach to getting the wider fashion community to collaborate, co-create, and make better-aligned decisions?

Our belief is that DPC should be regarded as a cultural transformation in the fashion industry, with technology serving as one of the tools to achieve this shift. The key to realizing this transformation lies in automating the extraction and application of data required for day-to-day operations without additional effort from practitioners. True innovation occurs when professionals, such as designers, developers, and production teams, can focus entirely on their core work rather than being burdened by manual data entry and analysis.

Unfortunately, most traditional PLM systems in the fashion industry have treated data entry and analysis as integral parts of the workflow, making it difficult to fully capitalize on the benefits of data utilization. In contrast, industries like automotive and industrial design have successfully implemented 3D PLM systems for over a decade, leading to significant workflow and cultural shifts. This success is largely due to the wealth of actionable data already embedded within 3D files, which has driven meaningful innovation.

The same potential exists for the fashion industry. Current DPC solutions are evolving into 3D-based platforms designed to support cultural and operational transformation. However, the fashion industry faces unique challenges compared to other sectors, as it must produce a much greater variety of items within shorter timeframes. To overcome these challenges, innovation is needed in areas such as:

- Simplifying the creation of fabric, trim, and garment assets.

- Automating data extraction and analysis.

- Supporting data-driven workflows, including tools to easily generate tech packs, POM, and BOM based on 3D data.

Our solutions, including but not limited to CLO and CLO-SET, are designed to address these challenges. By enabling easier asset creation, automating data integration, and providing tools that streamline complex workflows, we are helping the fashion industry move toward a more efficient and innovative future where the focus can return to creativity and product excellence.

One of the selling points of 3D working has always been virtual sampling: a way to cut costs, reduce time to market, and blunt some of the environmental impact of iterative and redundant sample creation. This promise has been advertised for so long, though, that it no longer feels novel – and the reality of it has been difficult to quantify. What’s your perspective on how real the positive impact of 3D on the environment, and on people has been? And what, if anything, needs to change for that well-worn vision to be realised?

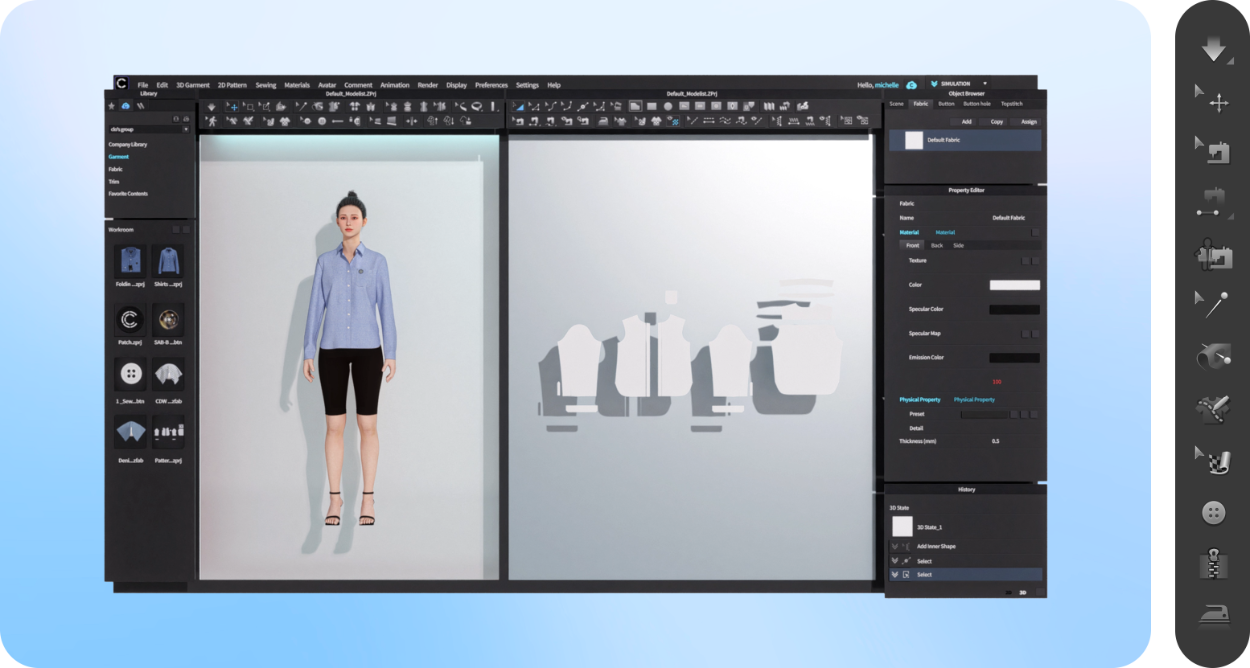

The creation of 3D garments provides significant benefits in the design phase by enabling various iterations and reducing the time and cost associated with physical sample production. However, from the perspective of practitioners and companies, this can sometimes feel like an additional workload. Beyond creating and reviewing 3D garments, practitioners often spend a significant amount of time managing related tasks, such as preparing tech packs, POM, BOM, and construction sheets. To truly achieve cost savings and lead-time reduction, 3D platforms must streamline these processes, allowing practitioners to focus on their core responsibilities.

For some of the fast fashion companies, production decisions are made based on consumer feedback after samples are created, often leading to overproduction and waste. In contrast, 3D technologies can reduce fabric consumption by minimizing physical samples during the design and development stages and can also aid in recycling surplus inventory. Furthermore, 3D can be utilized throughout the entire lifecycle of a garment, including presales to gauge consumer reactions and optimize inventory levels. This ability to cut waste across the lifecycle has the potential to make a massive, measurable impact on sustainability in the fashion industry.

Beyond operational and environmental benefits, 3D and other digital technologies contribute to a fundamental shift in how work is performed in the fashion industry. By reducing time spent on labor-intensive, repetitive tasks like manual data entry, double-checking, and redundant operations, these technologies free up practitioners to focus on more creative, value-driven tasks. This shift not only enhances efficiency but also fosters a less stressful, more fulfilling work environment.

For example, practitioners could spend more time designing innovative products or refining creative concepts rather than managing tedious details. This transformation echoes a broader trend in the digital era, where technologies like AI are helping to reallocate human effort toward creative and intellectual pursuits. In essence, 3D technologies support the evolution of human work by amplifying creative thinking and reducing the mental burden of repetitive tasks—making the industry not just more efficient but also more human-centric and sustainable.

Until now, the physical fashion world and the virtual fashion world have developed largely independently of one another. While there have been intersections—such as using the same technologies to create CG costumes for live-action films or hiring CG modelers in fashion companies and fashion designers in VFX studios—these instances remain limited. The virtual fashion industry within games and metaverse platforms faces similar challenges. Most virtual garments are designed by platform developers and offered to players. However, gamers increasingly seek trendy, fashion-forward clothing in these virtual spaces, and the supply often falls short of demand.

Although CLO has enabled fashion brands to create a vast number of garments, these garments are not easily integrated into gaming or virtual platforms. Why? Because converting garments for virtual platforms requires significant effort, including:

- Auto-sizing: Adjusting garments to fit various game character sizes.

- Rigging: Ensuring garments move naturally with character animations.

- UV Map Baking: Efficiently creating texture maps.

- Polygon Optimization: Reducing polygon counts to meet game performance requirements.

Recently, we have developed technologies to automate these processes, drastically simplifying the integration of garments into virtual platforms. As a result, it is now much easier for anyone to design clothing for games. Furthermore, these virtual garments can also be produced as physical garments for real-world use.

This creates an entirely new environment where virtual fashion designers can gain recognition, potentially becoming household names. In the near future, we anticipate a world where digital fashion brands evolve into luxury fashion brands, and their designers achieve widespread fame. This merging of virtual and physical fashion worlds is set to create a dynamic ecosystem with endless possibilities for innovation and creativity.

By bridging the gap between physical and virtual fashion, we envision an exciting era where the boundaries between these two worlds blur. This transformation will not only change how fashion is designed, consumed, and experienced but also open up unprecedented opportunities for collaboration, expression, and innovation in the industry.

To realise the long-term vision for a complete “digital twin,” it should be possible for any decision across the extended product lifecycle to be made based on a digital representation of the physical asset that travels across the extended ecosystem, with total trust. Which of those decisions do you think meet that high bar today? And which do you believe has the furthest distance to travel?

Achieving a complete digital twin of a garment requires digitalizing not just the garment itself but all its components, such as fabric, zippers, and buttons. For this to be truly effective, the digitalization process must capture not only the visual and physical properties of these components but also their meta-information (e.g., supplier details). However, due to the complexity of this process, achieving full automation remains a significant challenge.

Before garments can be fully digitalized, it is essential to first digitalize individual components like fabric and trim. However, this task is inefficient if every fashion company undertakes it independently. Components such as fabrics and trims are often shared across multiple brands. If each company creates its own digital version of the same material, it can lead to inconsistencies and duplicated effort, ultimately reducing efficiency across the entire industry.

The most practical approach is for fabric and trim manufacturers to handle the digitalization process at the source. However, not all manufacturers are equipped to do so, and there are many cases where digitalization is not feasible at their end. In such situations, companies can rely on services like Swatchbook, which specializes in digitalizing fabric and trim assets. Alternatively, for publicly available assets, platforms like our CONNECT provide an ideal solution. CONNECT has onboarded numerous fabric and trim suppliers, enabling them to share and sell their digital assets directly on the platform.

For trims, digitalization is relatively easier since they are hardware components, and manufacturers often already have CAD files for their designs. However, fabric digitalization remains more challenging due to the physical nature of the material itself. To address this, we are developing a new device that can easily measure both the visual and physical properties of fabrics. This innovation will make it significantly easier to create digital twins of fabrics, helping to bridge a major gap in the digitalization process.

By facilitating fabric and trim digitalization through specialized tools and platforms, we are working to establish an ecosystem where fashion brands can efficiently access accurate digital assets without duplicating efforts. This will not only save costs but also ensure consistency across the fashion industry, paving the way for a more seamless and scalable implementation of digital twin technology.