Released in The Interline’s DPC Report 2024, this executive interview is one of a nine-part series that sees The Interline quiz executives from major DPC companies on the evolution of 3D and digital product creation tools and workflows, and ask their opinions on what the future holds for the the extended possibilities of digital assets.

For more on digital product creation in fashion, download the full DPC Report 2024 completely free of charge and ungated.

Key Takeaways:

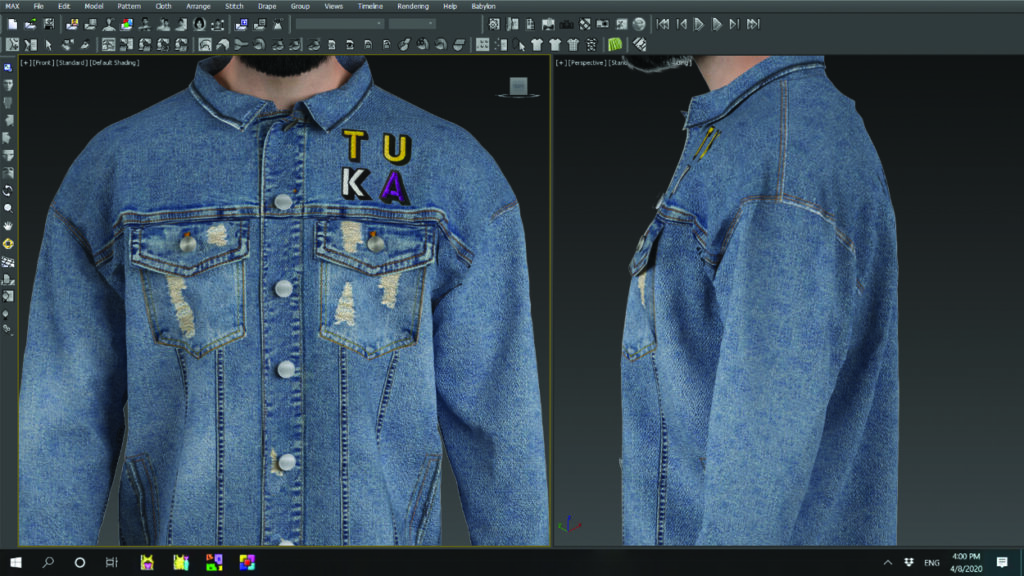

- Cost Savings and Efficiency: DPC tools like TUKA3D can significantly reduce the need for physical samples by up to 70%, leading to substantial cost savings and resource conservation. Digital prototyping accelerates design iterations, enhancing a brand’s ability to respond to market trends quickly.

- Open and Interoperable Systems: Tukatech emphasises open systems, allowing seamless import and export of 3D garment elements across various platforms. This ensures that digital assets remain compatible and accessible, regardless of the software used.

- Digital Design to Production Flow: Tukatech has successfully implemented a fully digital design-to-production flow, integrating 3D design with pattern-making, manufacturing systems, and virtual sampling. This holistic approach minimises the need for physical samples and streamlines the entire production process.

In a difficult climate for fashion (and retail in general) new and ongoing investments in tech and talent-intensive initiatives like digital product creation can be harder to justify. Do you believe the business case for 3D / DPC is strong enough? And how is that business case evolving to meet a changing industry?

Investing in Digital Product Creation (DPC) tools like TUKA3D offers a compelling business case for fashion companies, even amid challenging economic conditions. The evolving landscape of the fashion industry underscores the growing importance of such technologies.

According to Boston Consulting Group, implementing 3D design tools can substantially decrease the need for physical samples by up to 70%. Many TUKA3D users do not make physical samples, conserving resources and reducing costs. Digital prototyping enables rapid iterations, allowing brands to adapt swiftly to market trends and consumer preferences, enhancing competitiveness. By relying on digital samples, companies can reduce material waste associated with traditional sampling processes, aligning with sustainability goals.

Our Patented process, utilizing TUKAcloud, facilitates seamless collaboration between design, production, and marketing teams, ensuring alignment, faster approvals, and reduced operating errors.

The business case for TUKA3D and similar DPC tools is robust. They offer tangible benefits in cost savings, sustainability, operational efficiency, and strategic agility.

As the fashion industry evolves, embracing digital transformation becomes crucial for maintaining competitiveness and meeting market and environmental demands.

A lot of the long-term promise of digital product creation hinges on the assumption that systems, files, and processes will be open and interoperable – allowing companies to go after new opportunities as they emerge, instead of always being beholden to a single vendor. How are you seeing that work in practice? And what do you believe are the keys to maximising compatibility in order to get the most value out of digital assets, platforms, and workflows?

Tukatech recognizes the critical importance of open and interoperable systems in Digital Product Creation (DPC), which empowers companies to seize emerging opportunities without being confined to a single vendor.

In practice, Tukatech has taken significant steps to promote interoperability. Starting with TUKA3D 2022: This version offers an open system that allows users to import and export all main elements of a 3D garment across various fashion 3D systems. This flexibility enables designers to utilize different software tools while maintaining workflow consistency.

We ensure that the 2D patterns are intact and ready for production, that the FABRIC is converted from physical to digital state with ZERO difference, and that there is zero difference between the AVATAR and the actual FIT MODEL.

By providing TUKAforms, life-like fit model clones that can be made using actual 3D scan data, we ensure that avatars are consistent across different platforms. This standardization facilitates accurate fit assessments and seamless data exchange between systems.

Tukatech aims to enable companies to fully leverage their digital assets and remain agile in a rapidly evolving industry by focusing on these areas.

It’s become a bit of a well-worn argument that DPC should be delivering on more than just design and visualisation, and that a 3D garment should be evolving to serve as a product definition, so it can directly drive production. The reality today, for most organisations, is very different: it remains a process of iterative physical sampling, reliant on 3D files being accompanied by flat technical specifications. You’ve told us before that Tukatech’s customers are different and that a fully digital flow – from 3D design to production – is the current state for most of them. What have you done differently to mature that design-to-production flow?

Tukatech’s success in establishing a fully digital design-to-production flow lies in addressing the practical and systemic barriers that often hinder other organizations. Tukatech has created an ecosystem that allows its customers to harness the full potential of 3D product creation by focusing on technology, processes, and education.

Here’s what has been done differently: Tukatech’s 3D solution (TUKA3D) is tightly integrated with its pattern-making software (TUKAcad), ensuring that 3D garment designs are visual concepts and precise, production-ready patterns.

Unlike other platforms, Tukatech’s focus extends beyond rendering. The software outputs detailed technical data, including accurate fabric consumption, measurements, and construction details, enabling direct manufacturing use.

Advanced simulation ensures that garments behave like real-world products, with accurate draping and fit validation. This minimizes the need for physical sampling by identifying issues in virtual prototypes.

Tukatech has prioritized interoperability with manufacturing systems, ensuring that 3D designs seamlessly translate into cutting machines, sewing workflows, and PLM systems.

Tukatech customers are encouraged to rely on virtual samples for decision-making, cutting physical sampling by up to 90%. This is achieved by creating photorealistic renderings and using virtual fit sessions that mimic real-world conditions.

Tukatech’s solutions provide a single source of truth, with all stakeholders, from designers to manufacturers, working off the same digital assets. Tukatech invests heavily in customer training, helping teams understand how to utilize 3D-to-production workflows. This includes workshops on digital pattern-making, fit validation, and virtual sampling.

Recognizing that every organization has unique challenges, Tukatech customizes its solutions to integrate with existing processes, ensuring smoother adoption. Tukatech’s leadership has been vocal about the benefits of digital transformation, creating awareness and pushing the industry toward a more integrated approach.

While many organizations struggle to integrate 3D with production due to fragmented workflows and limited software capabilities, Tukatech has designed its ecosystem to make the transition natural and effective by focusing on practical solutions and providing end-to-end support.

The maturity of Tukatech’s design-to-production flow stems from its holistic approach to technology, integration, and education. By aligning tools with real-world manufacturing needs and empowering customers to embrace digital-first workflows, Tukatech has set a benchmark for what’s possible in 3D/DPC since 2001.

One of the big promises of 3D has always been accessibility and agility – the idea that digital design provides the shortest distance between having a vision and bringing it to life and then testing that new idea with colleagues and even consumers. There’s a similar kind of democratisation going on in production, with the microfactory model gaining more traction, and brands recognising the potential of producing on-demand, as close as possible to the consumer. What role do you see DPC playing in making this model more viable and more widespread?

Digital Product Creation (DPC) plays a pivotal role in making the microfactory and on-demand production model more viable and widespread. By reducing barriers in design, enabling hyper-localized manufacturing, and promoting efficiency, DPC is helping brands realize the promise of democratized production. Tukatech’s early emphasis on micro-factories in 2012 was forward-thinking, and today, Digital twins created using DPC provide highly accurate, production-ready files. These files can be sent directly to microfactories, minimizing the need for manual intervention. On-demand production thrives on flexibility, and DPC supports this by allowing brands to adapt designs based on consumer preferences or feedback without disrupting workflows.

With microfactories strategically placed near consumer hubs, DPC enables localized production by providing digital assets that can be shared instantly. Microfactories, combined with DPC, allow brands to produce personalized products on a larger scale without sacrificing efficiency.

Tukatech has set up hundreds of factories around the globe who followed the concept of selling and then making. We call this REVERSE THE PROCESS (see here for more details).

One of the most significant benefits is for Brands, who can use DPC-generated digital prototypes to gauge consumer interest before committing to production. This ensures that only validated or even sold product designs are produced.

Tukatech’s early advocacy for microfactories underscores the enduring relevance of this model, with DPC driving its future scalability and adoption. Obviously a lot of attention is being paid to AI right now – both standalone and as a new component of the DPC ecosystem. Do you see any use cases where AI is actually making tangible improvements to the way fashion handles design, development, and production workflows? And does AI have a role to play in helping the industry overcome the final hurdle and really commit to using digital samples to replace physical ones for virtual photography?

AI is increasingly proving its value in fashion by streamlining design, development, and production workflows. It holds significant potential to address critical challenges like adopting virtual samples.

TUKAcad APM is an automated Pattern Generation system that allows users to open existing reference blocks, input new measurement data, and automatically create new production-quality patterns updated for the new style.

TUKA3D is integrated with EcoShot from Tronog, a technology that utilizes AI to enhance the realism of digital samples. This addresses a key barrier to adoption: stakeholder skepticism about whether virtual photography can truly replicate and replace the need for physical photoshoots.

We have also introduced an enhancement to the Adobe Photoshop print design plug-in that uses the AI engine to automatically create seamless repeats with the click of a button.

AI is making tangible improvements to design, development, and production workflows and addressing key barriers to adopting digital samples for virtual photography. By enhancing realism, reducing costs, and increasing efficiency, AI plays a vital role in helping the fashion industry fully commit to digital transformation, making the vision of a seamless, sustainable, and agile workflow a reality.

To realize the long-term vision for a complete “digital twin,” it should be possible for any decision across the extended product lifecycle to be made based on a digital representation of the physical asset, with total trust. Which of those decisions do you think meet that high bar today? And which do you believe has the furthest distance to travel?

The vision of a “digital twin” as a complete and trusted representation of a physical garment throughout its lifecycle is ambitious but attainable, with platforms like TUKA3D already advancing certain aspects. However, the degree to which TUKA3D meets this vision varies across the product lifecycle.

Here’s an assessment of where it excels and where it has room to grow, TUKA3D excels in providing accurate visual and functional representations of garments during the design phase. Its ability to simulate fabric drape, fit, and construction allows designers to validate aesthetics, fit, and functionality digitally. Designers and stakeholders can trust that virtual samples in TUKA3D accurately represent what the physical garment will look and behave like, minimizing reliance on physical prototypes.

TUKA3D platform includes detailed fabric libraries with data on stretch, weight, and texture, enabling highly accurate simulations. This helps teams make informed decisions about fabric selection and consumption without needing physical swatches.

Virtual samples generated in TUKA3D are often used for final stakeholder approvals before production. With photorealistic rendering and accurate fit simulations, marketing teams and buyers can confidently greenlight designs for manufacturing.

TUKA3D integrates seamlessly with TUKAcad for pattern-making, allowing accurate calculations of fabric consumption and production costs directly from the digital twin. Though TUKA3D is strong in design, it doesn’t yet fully replicate real-world manufacturing conditions, such as machine tolerances or production variability. Trusting a digital twin to replace physical quality control processes entirely remains a stretch.

These supply chains will need to become more agile, with companies making efforts to reduce excess inventory and minimise the risk of shortfalls. Margin pressures, as well as pressures from governments around the world to reduce emissions and fashion waste, will drive advances in inventory management. New technology will aid these efforts.