Released in The Interline’s DPC Report 2026, this executive interview is one of an eight-part series that sees The Interline quiz executives from major DPC companies on the evolution of 3D and digital product creation tools and workflows, and ask their opinions on what the future holds for the the extended possibilities of digital assets.

For more on digital product creation in fashion, download the full DPC Report 2026 completely free of charge and ungated.

For a while now the broad shape and scope of 3D and DPC strategies have been generally accepted, but now companies are asking some fundamental questions about how far those initiatives should stretch. Some see a clear opportunity to take them further. Others potentially see arguments for either ringfencing them where they stand, or possibly even scaling them back. Technology footprints will always morph over time, but this feels like a deviation from the standard. What’s your perspective, as a company with a very unique vantage point on digital product creation?

There certainly was a period when the fashion industry rapidly accelerated efforts to digitalise workflows in design and prototyping under the banner of digital transformation. Thanks to these efforts, DPC gained attention, and numerous 3D software and related services emerged. As the main objectives of DPC include improving development speed, reducing costs, and promoting sustainability, we believe that this evolution should not stop here but must be further advanced.

The objective is the proliferation of DPC throughout the industry so that its usage becomes the norm. To realize it, we must make the effort to convince the industry that this technology is worth adopting, by making it possible for users to reap the benefits promised by it. Although trends to embrace sustainability and tackle waste have encouraged investment in DPC and with measurable results, there have also been cases where outcomes have fallen short of expectations, especially in the real-life producibility of digital products. I suspect this has been a major factor preventing DPC from catching on. Therefore, the use of DPC must not be limited to within the digital realm, rather it must facilitate smoother integration with real-world production processes. By doing so, the full potential of DPC can be unlocked, leading to further improvements in cost-effectiveness. To that end, establishing an operational framework that seamlessly combines both digital and physical aspects will be key.

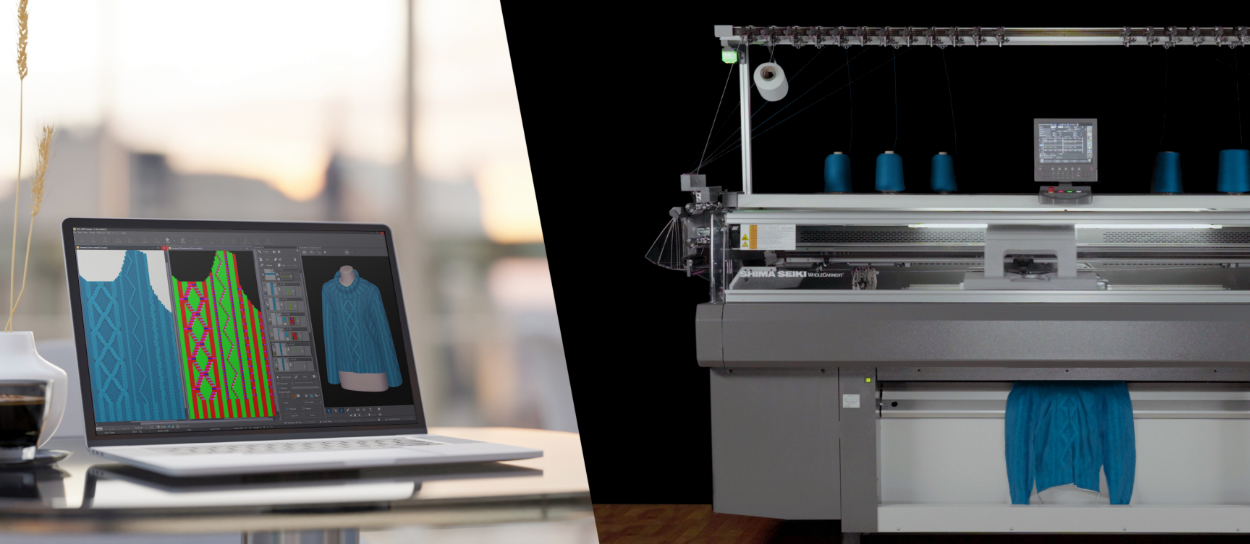

This is where we come in as manufacturer of production machinery. Our mission is to provide a direct link from DPC to manufacturing. Moreover, this is not just about accurately conveying design intentions digitally from studio to factory; suppliers can also take advantage of DPC. We are already seeing this trend among our machine customers, who as suppliers are making proposals leveraging their own expertise in knitting and materials, allowing both sides to accelerate product development and co-create new products through two-way communication based on digital products. We will continue to advance these solutions further to promote automation and labour-savings from product development through prototyping and on to production, thereby contributing to digitalisation and sustainability throughout the entire supply chain.

Most 3D / DPC companies began life selling software, and have spent the majority of their time in the market further developing and refining that software. Some of them have subsequently launched hardware of their own – primarily in material testing – but most are still software-first. SHIMA SEIKI is different in this respect, since the company was founded in 1960s as a manufacturer of textile machinery before getting into DPC solutions. What was the motivation behind that move?

The fashion industry has long operated on a model of mass production, over-stocking and discarding of unsold inventory. This approach generates significant waste and proves unprofitable as a business model. Consequently, product prices have become inflated, creating a vicious cycle where products do not sell at proper prices because consumers wait for bargain sales. Furthermore, the environmental impact is enormous.

One solution we proposed 30 years ago called the Total Fashion System, a design-centric knit production system that used fabric simulations called “virtual samples” to replace actual sample-making. This was back in the day when keywords such as “sustainability” and “SDGs” did not exist yet, so the proposal was purely for the sake of efficiency and eliminating waste from the planning, design and evaluation process in knitwear production. In hindsight, it may well have taken none other than a machine manufacturer that knew first-hand about current problematic areas to arrive at such a solution. As such, SHIMA SEIKI’s Total Fashion System is arguably the first application of commercial DPC in fashion. At around the same time we reduced waste and enhanced efficiency from the production process as well, with the advent of the WHOLEGARMENT® knitting process which could produce a garment in its entirety in three dimensions. From this development arose the need for 3D virtual sampling.

In this way, our motivating factor for DPC technology came about by recognising the inherent problems of the fashion industry from the perspective of a machine manufacturer and resolving to improve the industry at the earliest stage. We have been driven by a strong conviction to utilise digital sampling technology ever since, to transform the fashion business into a sustainable model and have worked tirelessly towards this goal for the past 30 years.

One of the key questions that shapes digital product creation strategies is how closely the output of 3D design, simulation, and visualisation tools captures the producible reality of the garment. What’s your perspective on the importance of this link between physical and digital? And how do you think your perspective on this has influenced the way you build DPC solutions compared to software-first companies?

It is precisely because we are a textile machinery manufacturer with comprehensive expertise in knitting that we can develop dedicated design and simulation functions tailored to the characteristics of knits. A major strength lies in the fact that our digital samples do not merely serve as realistic visualisations, but also seamlessly connect to subsequent production processes. Therefore, our perspective on the link between physical and digital is that of extreme importance.

As a machine manufacturer we examined the entire supply chain, and concluded that if you take the lowest common denominator of a knitted garment—the knitted loop and the yarn—and make that realistic, then the entire simulation of the garment becomes as realistic as it gets. That is why our fabric simulations are based on actual production data for forming knitted loops and begin with the scanning of actual yarn. Furthermore we provide a web service dedicated to digitising yarn by yarn manufacturers from around the world and letting our customers use them in their simulations free of charge. When the garments based on those simulations are physically produced using the actual yarns, they will end up matching the simulations precisely. When comparing realism among fabric simulations, the fact that we use real yarns is almost like cheating, isn’t it (laugh)?

There’s no question that specialisation leads to depth of functionality, and SHIMA SEIKI’s history in building machinery for flat knitting certainly fits that brief, but does it also create any limitations? Is your focus purely on digital solutions for knitted textiles, or do you cater to other product types and market segments as well?

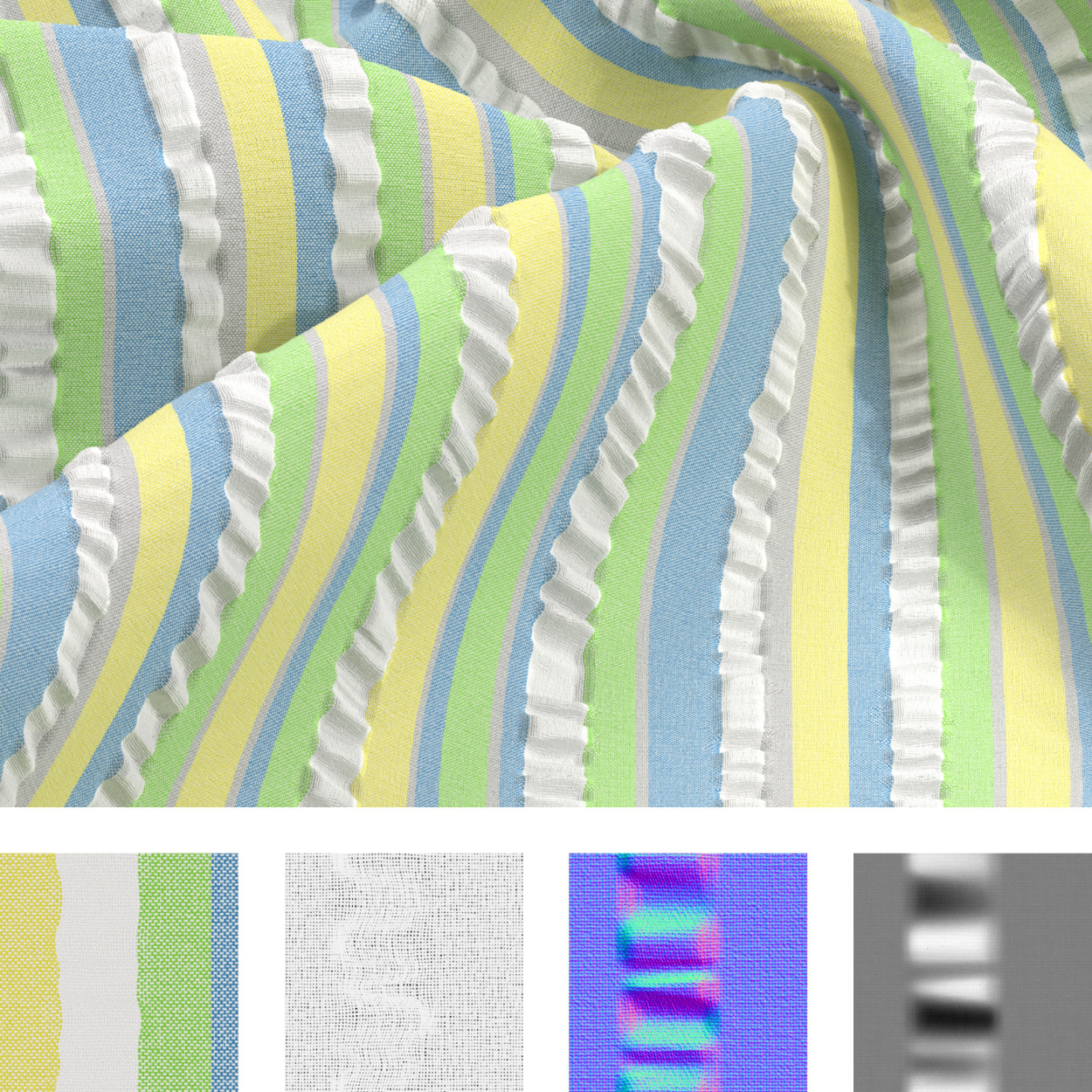

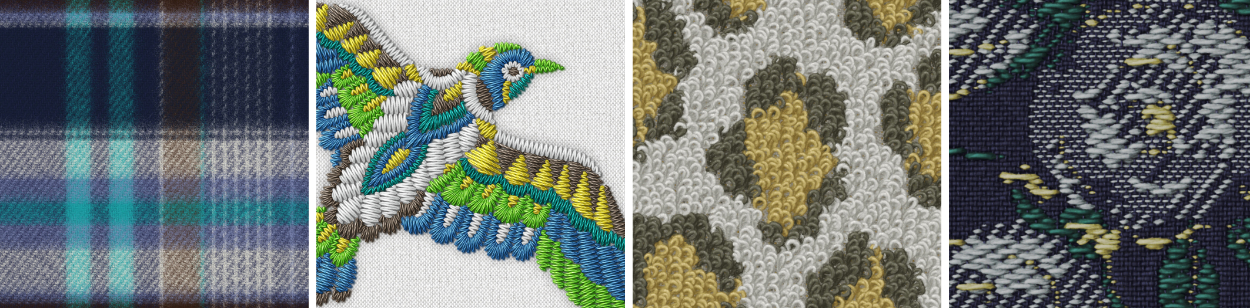

As a matter of fact, fabric design simulation on APEXFiz® covers a wide range of textile applications besides flat knitting, including circular knits, woven fabrics, embroidery, and even pile or towel fabrics. For those areas where we lack production machinery, we collaborate with partner companies in those fields to ensure seamless transition to manufacturing. We also facilitate data exchange with other companies by supporting common formats. As with our knit simulations, our fabric simulations of other types of textiles are also very realistic, and many users opt to utilise APEXFiz® alongside other 3D software.

What’s your perspective on the impact that AI is having on 3D platforms (and on design software for fashion and textiles in general)? Do you see an opportunity to bridge some of the benefits of AI and the grounding required to ensure that every stakeholder is working towards the creation of products that are actually producible?

It is true that advances in generative AI have enabled instantaneous idea generation and concept design, alongside the ability to produce vast quantities of variations. The role of 2D and 3D design and simulation software is undoubtedly changing.

However, creating designs that precisely match the envisioned concept remains challenging for current AI capabilities. Even when generating images that appear realistic, whether that item is producible is an issue, not to mention they often lack the essential information required for production. Achieving a seamless workflow through to production remains challenging for AI on its own.

Moving forward, a hybrid approach combining generative AI for efficient idea generation, design software for concrete design creation, and integration with production will be required. We aim to contribute to digital transformation of the fashion industry by providing solutions aligned with this evolving trend.

What’s the most useful question that companies can ask themselves, right now, to better understand what they want to accomplish next with 3D – whether that’s driven by their own ambitions, or by changes in the market?

Although the use of 3D, DPC and generative AI ought to be improving communication between brands and suppliers, that does not necessarily seem to be the case. Therefore, I would like current DPC software users to ask themselves, “To what degree can digital samples be realised as final products?” Even if many excellent digital samples are created, that is not the goal. If those samples cannot be produced, those efforts are wasted. Moreover, there is a tendency to create an increasingly large number of digital samples simply because they are digital, but that can create an additional burden of having to choose from among so many of them.

As I mentioned in my answer to the first question, we must remind ourselves of our goals in terms of how fashion can benefit from DPC: How much lead time can be reduced across the entire supply chain and how much inventory risk can be minimised.

*SHIMA SEIKI, APEXFiz, yarnbank and WHOLEGARMENT are trademarks or registered trademarks of SHIMA SEIKI MFG., LTD. in Japan and/or other countries.